For boom hoist ropes on mobile cranes in particular, proper and timely inspection is the most important aspect for safe use. Although improper use or maintenance can cause a wire rope to wear out prematurely, proper and timely inspection will ensure that the rope is removed from service before it becomes unsafe.

Inspection procedures and broken wire removal criteria are available from several sources. ASME B30.5 Safety Standard for Mobile Cranes is the one of the most recognized sources for this information. The Wire Rope Technical Board publishes a Wire Rope Users Manual that also contains this information. These documents provide all the information necessary to develop an inspection procedure to make sure inspections are done at the proper frequency and the rope is retired at the proper time.

It may seem to be a rather simple task to inspect a wire rope. However, there are several important issues that must be understood and followed to conduct a proper wire rope inspection. These key issues are:

- Why and how boom hoist wire ropes wear out

- How to inspect

- Where to inspect

- Retirement criteria for boom hoist ropes

- Special considerations

Why and How Boom Hoist Wire Ropes Wear Out

Boom hoist ropes can be used at a combination of a low design factor (minimum of 3.5:1) and a smaller bending ratio (15:1) than other operating ropes on a crane. Ropes run at 3.5:1 design factors and 15:1 bending ratios will wear out much faster than ropes operating at 5:1 factors and 18:1 ratios. Additionally, boom hoist ropes are subjected to their highest stresses when picking the boom off the ground. When the boom is on the ground, only the first layer of rope is typically on the drum. Therefore, that first layer is subjected to the highest crushing stresses when the boom is being raised. Broken wires can develop due to these crushing forces, especially at the cross over and step up points on the drum.

If the crane is doing duty cycle work with constant movement of the boom, that at times may include moving the boom with a load on the main hoist, the rope in the boom hoist reeving is subjected to severe bending stresses. In these cases the bending stresses will cause fatigue wire breaks and the rope will have to be removed due to exceeding the ASME B30.5 broken wire removal criteria.

Remember, if the boom hoist rope is reeved 18 parts, one cycle of lifting and lowering a load can cause up to 32 bends of some sections of rope in the reeving but only two bends of the rope on the drum.

Depending on the application, a boom hoist rope can either wear out on the drum from crushing or in the reeving from bending fatigue, depending on which is the most highly stressed location. Experience shows that the inspector needs to know the history of the crane and understand the application to know what to expect.

Another important aspect of boom hoist rope bending fatigue is wire break behavior if using synthetic sheaves. Synthetic sheaves tend to allow wire breakage to develop in the interior of the rope rather than the exterior of the rope due to a different stress pattern. With steel sheaves, the highest contact stresses occur at the outside wire to steel sheave contact point. Therefore wire breaks develop on the exterior of the rope and are more easily detected by visual inspection. With synthetic sheaves the highest contact stresses are shifted to the interior of rope causing wire breaks at either the strand to strand or strand to the independent wire rope core (IWRC) contact point. These wire breaks are much more difficult to detect by visual inspection.

How to Inspect

The ASME B30.5 Standard requires all rope expected to be in use during a work shift to be inspected daily using the proper tools, like the Mazzella Crane Rope Inspection Toolkit. This means the entire length of the boom hoist rope as any lifting and lowering of the boom requires the entire length of the rope to be used.

Just looking at the rope on the drum is not enough. Access to the entire length of rope is critical for a good inspection. The inspection must be conducted in sufficient light and the inspector must be in close proximity to the rope. The use of a set of binoculars or other methods of magnification is not sufficient to inspect the rope 20’ or 300’ above the inspectors head.

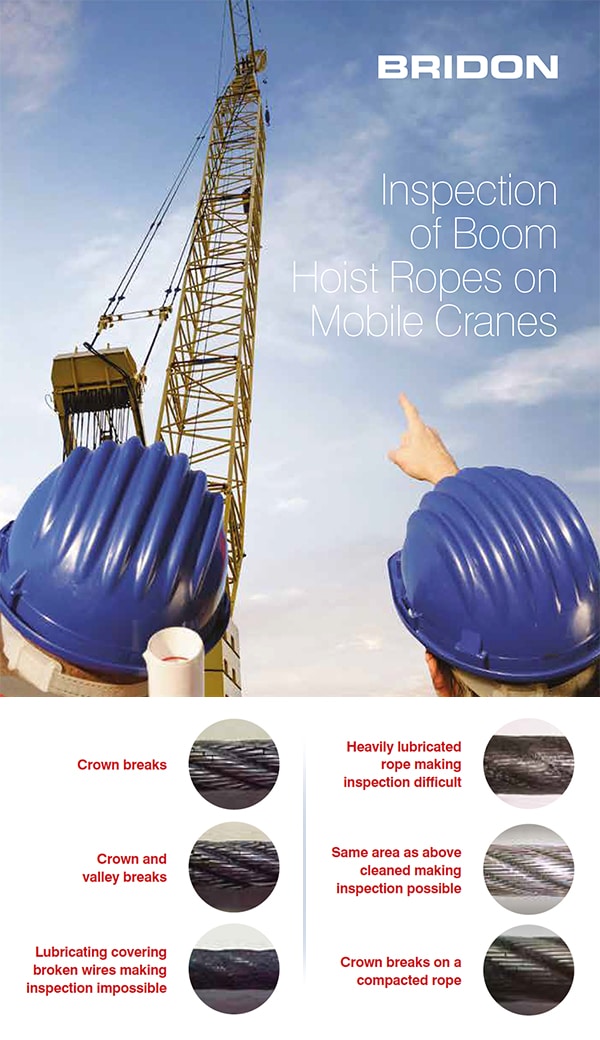

The rope surface must be clean. If the rope surface is covered with a thick or dark coating of lubricant the rope cannot be properly inspected and must be cleaned in order to make a proper inspection.

Where to Inspect

Although the entire length of the rope has to be inspected, there are four critical areas where broken wires can be expected to develop depending on type of reeving and application.

The drum cross over and step up points are the high stress area where crushing damage can be expected.

If the rope is doing a job requiring a significant amount of booming then the rope in the reeving must be inspected for wire fatigue breaks.

If the rope is reeved to a double drum with an equalizer sheave, then the rope operating on the equalizer sheave is a wear area and needs to be inspected.

Wire breaks in the area of the equalizer and in the reeving can be either exterior or interior (valley breaks) and the inspector must look closely for both types of breaks.

What to Look For

Broken wires and damage are the major problems associated with boom hoist ropes. Crushing damage and broken wires at cross over points and step up points are relatively easy to see.

Wire fatigue breaks at the equalizer sheave or in the reeving can be more difficult to see and it is important that extreme care is taken when inspecting these areas of the rope.

Compacted strand ropes and compacted ropes can also be more difficult to inspect as the broken wire ends may not separate to the same extent as conventional ropes and a broken wire may only look like a crack across the axis of the wire. It may be necessary to take the load off the rope and bend the rope by hand in these areas so that wire breaks are more visible. A good method to use when wire fatigue breaks can be expected is to compare rope diameter in an unworn section to the diameter in the worn area. When the rope diameter is reduced by 3 or 4% from the unworn diameter, wire breaks can be expected to develop. Another method is to look for red rust (oxidized metal particles) between the strands. This is an indication of internal wear that could lead to wire fatigue breaks at either the strand to strand or strand to IWRC contact points.

Retirement Criteria for Boom Hoist Ropes

The following are retirement criteria for boom hoist ropes:

- Three broken wires in one strand or six broken wires in one lay

- Since Rotation Resistant ropes are allowed to be used as luffing jib boom hoist ropes, retirement criteria for these ropes is two broken wires in 6 rope diameters or four broken wires in 30 rope diameters

- One valley break

- Kinking, crushing, birdcaging or any other damage resulting in distortion of the rope structure

- Heat damage

- Corrosion

Note: Always refer to the latest edition of ASME B30.5 to confirm retirement criteria

Special Considerations

It must never be assumed that if the outside layers on the drum are in good condition the entire rope is in good condition. In many cases where the rope on the drum was in excellent condition with no broken wires, the rope in the reeving was found to be completely deteriorated.

Never assume that because the rope on a particular model crane typically wears out on the drum that every rope on that same model crane will do the same thing. The manner in which the crane is being used has a significant influence on whether the rope will wear out on the drum or in the reeving.

There are examples where a boom hoist on a particular model crane lasted three years on a job where there was practically no boom movement. Conversely, the same make and model crane on a job where the crane was doing duty cycle work with significant boom re-positioning and raising the boom with a load on the hoist rope, the boom hoist rope lasted 6 months or less.