Category: Rigging Inspections

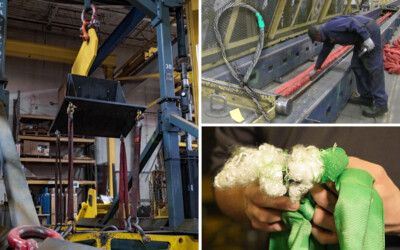

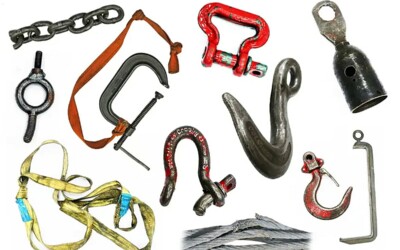

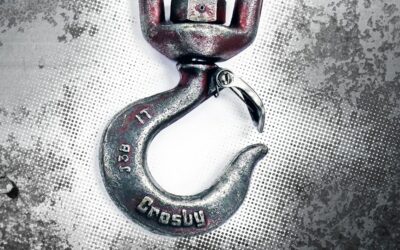

Rigging inspections are required by OSHA and ASME to be performed before use, on a periodic basis, and on a frequent basis according to language in OSHA 1910.184 and ASME B30 standards. Rigging inspections include the thorough evaluation of the condition of lifting slings, including wire rope slings, alloy chain slings, synthetic web slings, synthetic roundslings, high-performance roundslings, synthetic rope slings, and metal mesh slings. It also includes the inspection of rigging hardware including: sling hooks, shackles, eye bolts, manual hoists and chain falls, lever tools, and below-the-hook lifting devices.