Have you struggled to reach that maximum pull strength with some of your end fittings? Having a button installed on your crane ropes may be the answer you’re looking for to give you that maximum pull strength.

What can you do if an emergency Becket or another end fitting will allow you only to get close to maximum pulling strength, but not to 100%? The answer may be closer than you think, as Mazzella can install poured buttons on your wire rope, and that will allow you to reach the maximum pull strength.

Having been in the lifting and rigging business since 1954, Mazzella understands the investment you make in your equipment. We’re here to help you maximize your rigging gear, including your wire rope and cranes.

In this article, we will answer the following questions for you:

- What is a button?

- What does a button do for your wire rope?

- Does a button extend the life of a wire rope?

- What is the installation process for a button?

- Is there a break-in period for buttons?

What Is a Button?

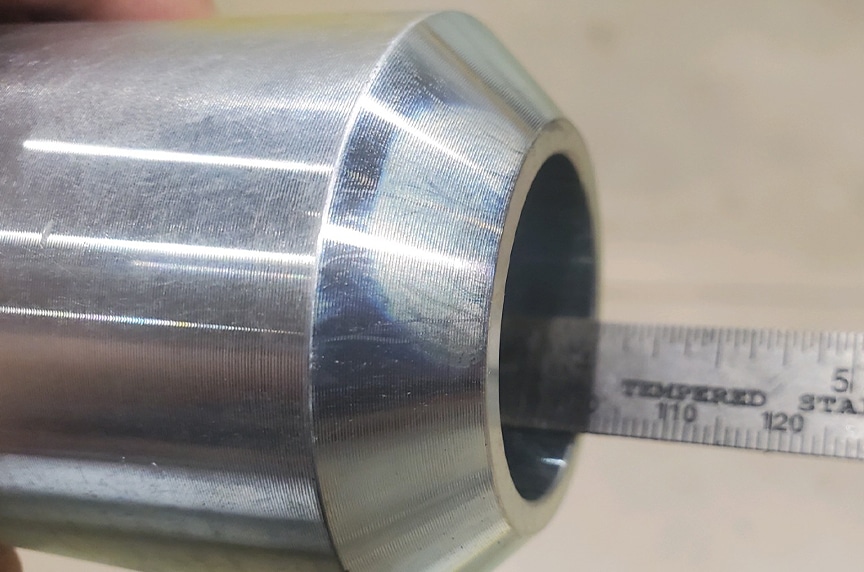

The button, like the Crosby Steel Swage Button, is the end fitting that goes on the end of a high performance crane rope on a quick-reaving crane. It fits into a cup that is attached to the crane itself.

The purpose for that is because with an emergency Becket, it is much more difficult for crane technicians to install in the field. However, Mazzella’s specialists can come out to your job site and put a button on your wire rope. Then, you can run the wire rope through your blocks, and be ready to return to operations quickly.

What Are the Benefits of Using a Button on a Wire Rope?

Using a button on your wire rope instead of other end terminations allows you to have 100% of the line pull (lifting capacity) versus an emergency Becket, where it’s approximately 80% of the line pull. Also, buttons allow you to significantly decrease the amount of time spent reeving your crane blocks.

With an emergency Becket, the rope goes through the end termination, makes a loop, and it has a wedge in-between it. Once the rope goes into that end fitting, a bolt goes through it and attaches to the crane.

Because purchasing new crane ropes is not a small expense, you want to do what you can to maximize the pulling strength. A button allows you to have a straight pull.

Why Are Buttons Gaining in Popularity?

In recent years, Mazzella Button Install Technicians have seen, in increasing numbers, that industries using wire rope have started using buttons. Previously, the Becket was the end fitting of choice to put a rope on a crane.

With buttons, you don’t have an exposed end that you would with an emergency Becket. The Becket goes through, and then, loops around. It comes back out, and you have typically 12” to 18” of exposed rope on the end of the strand.

Beckets are saddled with a clamp. Whenever you’re lifting your blocks up, the Becket can hit that block, which could make the cable open up.

What Is the Installation Process for a Button?

***Remember, Mazzella will only send certified individuals to conduct your button installs. If you go with another third-party company, make sure to ask about your installer’s certifications.

When a technician arrives on site, their first task is to observe the wire rope and locate the bad spot. From there, the technician will go the recommended distance further down the wire rope to make sure there are no other faults or cause for removal from service.

Once the location of the issue is found, our Button Install Technicians take measurements for the button, and take the following steps:

- Insert the wire rope into a stand

- Seize the cable to six times the rope diameter or one full length

- Measure the button

- Determine the measurements for where the button will go

- Cut the rope

- Slide the button onto the rope

A Button Install Technician will wrap a seizing wire around the crane rope near the end of the strand before installing the button. Think of this process like taping up the handle of a baseball bat before using it in a game.

After the button is on the rope, Button Install Technicians will open up every wire individually and put cleaner on it for a minimum of 15 minutes. Once that process is complete, Button Install Technicians will check for symmetry among the wires. Then, the stand is used to run the socket up the crane rope, where it will be checked for levelness.

When those steps are complete, Button Install Technicians will open up and pour in the wire lock above the exposed wires to make sure they are fully covered. This process prevents water from getting into the crane rope and rusting it from the inside out.

Once the curing process is complete, the installer will complete all post-pour examination to confirm it was successful. Then, the cap will be put on the button, and the installer will ensure the wire penetrated all the way through to the bottom of the end termination.

Is the Wire Rope Actually Cut During a Button Installation?

Typically, if a button installation is required on your crane ropes, it’s because riggers and operators have damaged the rope in some way. Sometimes, they’ll need Button Install Technicians to come out and shorten the cable.

However, Mazzella’s process says if we’re going to shorten that cable, we do it from the drum end, not from the socket end.

Are There Any Warnings for Usage of Buttons?

***It is important to note that Mazzella will never swage a button on a used rope. If anyone suggests they can swage a button on a used rope, you should STRONGLY CONSIDER using a different company. Regardless of your decision on a third-party company, always ask for certifications and references.

There are several warnings for the usage of buttons and end terminations on your crane ropes.

Steel Swage Button Warnings

Button lengths and wall thickness are directly related to rope capacity. If a shorter button length is required, the shorter button may not achieve the full holding capacity of the rope. Special size buttons — per your specifications — are available. Ask a Button Install Technician for more details.

S-421T Wedge Socket Warnings

Loads may slip or fall if the Wedge Socket is not properly installed. A falling load can seriously injure or kill workers on a job site. Read and understand these instructions before installing, and do not side load the Wedge Socket.

Apply the first load to fully seat the wedge and wire rope in the socket. This load should be of equal or greater weight than loads expected in use.

Also remember NOT to:

- Interchange wedges between S-421T and US422T or between sizes.

- Assemble an old style 1-1/4″ S-421W wedge into an S-421T 1-1/4″ TERMINATOR™ basket

- Place an old style UWO-422 wedge into a US-422T TERMINATOR™ basket

S-423T Super Terminator® Wedge Socket Warnings

Loads may slip or fall if the Wedge Socket is not properly installed. A falling load can seriously injure or kill workers on a job site. Read and understand these instructions before installing, and do not side load the Wedge Socket.

Apply recommended torque to tensioner and clip bolts, and properly install wire to securely lock tensioner bolt to tensioner. Do not assemble the S-423 Wedge in any brand or model socket basket other than the Crosby S-421T TERMINATOR™.

The size is marked on the socket basket and wedge, so do not interchange wedge between sizes.

For complete warning and application information, see The Crosby Group at www.thecrosbygroup.com.

How Can Mazzella Help You With Button Installations?

By reading this article, you now have a better understanding of what a button is, how it helps you maintain maximum pulling strength, why they are gaining in popularity, and what the installation process is like.

If a button installation is the right fit for you, our certified installers are available 24/7 for in-field OEM socket pouring for all major crane manufacturers. At Mazzella, our installers are retested every six months to make sure they are up to date on their certifications.

Mazzella stocks a large inventory of high performance wire ropes and wire rope products available for immediate delivery.

We stock our various high-performance ropes and products at our many locations in sizes from 1/4” to 3” diameter and 9 mm to 52 mm diameter. Also, we stock both domestic and non-domestic products ready for same or next-day shipment from one of our many service centers.

Email Craneropegroup@mazzellacompanies.com or call us at 800.362.4601 with any questions or to schedule your next crane rope project!

Crane Ropes

One Brand of Rope Will Not Work on Every Machine!

Mazzella stocks a large inventory of high performance wire ropes available for immediate delivery.

We stock our various high performance ropes at our many locations in sizes from 1/4” to 3” diameter and 9 mm to 52 mm diameter.

We stock both domestic and non-domestic products ready for same or next day shipment from one of our many service centers.

Copyright 2022. Mazzella Companies.