Winding Wire Rope

The manner in which wire rope is installed or wound on a drum or shipping reel will, to a large measure, determine the service life of that rope. Improperly wound ropes will cause undue crushing of the rope, doglegs, kinks, excessive abrasion and cutting of the individual wires.

Invariably, in winding wire rope onto a shipping reel or a coiling drum, the rope is wound over the top of the reel or drum. The fact that the rope comes from under the stock reel to wind reversely on top of the shipping reel has no effect on the physical condition of the rope, provided the stock reel is set at least 20 feet, or preferably more, from the rewinding machine.

The rope should be wound “thread lay,” with close, even winding throughout the length of the rope. If wound unevenly, the turns of rope bunch-up, cross wind and are liable to form doglegs, particularly on the more flexible ropes.

Never fill the reel full to the rim or edge of the flanges. If possible, leave a clearance equivalent to at least two layers of rope. This will save injury to the rope when the reel is rolled over obstructions on the ground.

The manner in which wire rope is installed or wound on a drum will, to a large measure, determine the service life of that rope. Improperly wound ropes will cause undue crushing of the rope, doglegs, kinks, excessive abrasion and cutting of the individual wires. Bad spooling also causes uneven application of force and motion. This results in fast fatiguing of the line from the end attachment to the drum.

Precautionary Steps

There are five precautionary steps that should be taken before starting the actual winding of the rope off the coil or shipping reel.

- A check should be made of the drum to determine the condition, size and shape of the grooves. If the drum is a smooth type, then the surface should be checked for straightness and smoothness

- Flanges should be checked to determine the extent of undercutting at the base

- Dirt, grit, filled grease or any other type of debris should be cleaned off.

- Bearings should be checked

- Cracks or breaks in segments of the drum should be reported

Whenever any of these five conditions are observed, the equipment should be removed from service and properly cleaned, repaired or replaced. This recommendation is made not just to improve or maintain good rope life, but to eliminate a potential hazard.

After establishing the satisfactory condition of the drum, the shipping reel is mounted on suitable jacks. The end is attached to the drum using the attachment provided. A tension should be induced into the line by providing some means of braking the shipping reel. A tight winding is imperative, particularly if multiple layer winding is required.

When winding a rope onto a grooved drum, the groove will properly guide the rope. If the rope is to be rewound on a smooth drum, then a helper should guide the rope, making sure each turn is winding tightly against the adjacent turn.

A lead or brass hammer is useful in tapping the line over as it is being wound. Do not use a steel head hammer or pinch bars. These can readily cause damage to the lines.

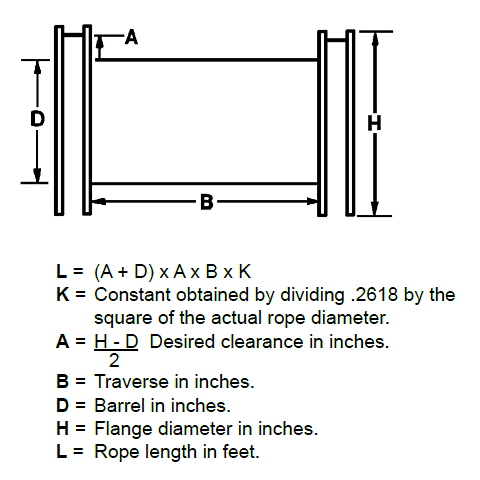

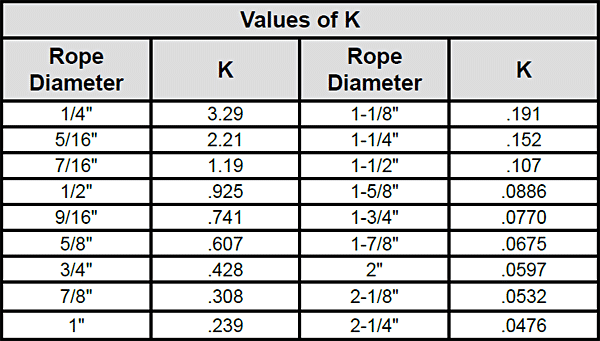

Calculating Drum Capacity

The length of rope that can be wound on a drum or reel may be calculated as follows. L = the length of the rope in feet. All other dimensions are in inches.