Efficiencies of Common Rope Splices, Knots, Bends, and Hitches

Better understand exactly what to expect from ropes which have been spliced, knotted or hitched.

This page has been compiled so that both our own personnel and those of our customers can better understand exactly what to expect from ropes which have been spliced, knotted or hitched.

All of the efficiencies listed herein either correspond with or take precedence over previously published figures.

Efficiency of Splices

Before discussing individual splices, it should first be understood that we have traditionally based our published rope strengths on tests using an eye splice at both ends. When tested, the ropes invariably part at the splice.

This may seem conservative, on our part, since a straight, unspliced line will have greater strength. However, it is hard to conceive an actual “in use” application where sufficient force can be applied to reach the breaking point without some sort of splice, knot or hitch being utilized. Occasionally, where small ropes may be tested by securing both ends with several turns around a post or cleat, break strengths at slightly higher than eye-spliced results may sometimes be achieved.

As you will see, in certain cases, obtainable splice efficiencies may sometimes suggest the desirability of using a slightly smaller diameter continuous length of line for a larger diameter, which must be long or short spliced.

Instructions for making the various splices are shown in specific brochures and booklets, which deal with the proper use of rope.

The test data were compiled using rope constructed of Nylon, Dacron, Polypropylene, Manila and P/D combinations. Percentage of efficiency varies little for ropes of dissimilar compositions used in the same type of splice.

Three Strand Construction

Eye Splice—As previously noted, our published strengths are based upon tests in which the rope is Eye Spliced at both ends. Therefore we can, for comparison purposes, consider this splice to be 100% efficient.

Besides being more closely related to actual field use, this splice is most convenient for test purposes since it offers the longest method of attachment.

It should be noted that only Eye Splice, either with or without a thimble, should be seized with marline or wrapped with tape for longer wear. When using a thimble for an Eye Splice with synthetic fiber rope, it is advisable to use an eared thimble for greater security.

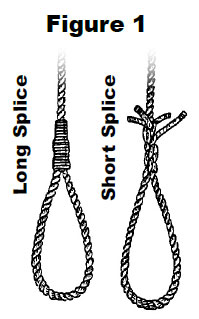

Short Splice—The Short Splice, which is used to join two ends, is essentially the same as the Eye Splice. If the splicer uses the same number of tucks back in each direction and tapers the splice in a manner similar to the Eye Splice, the efficiency, of the Short Splice will be very close to that of the Eye Splice (See Figure 1). The only disadvantage to the Short Splice is that it greatly increases the diameter of the rope at that point so that it may not pass through rings or over sheaves.

Long Splice—You will note in Figure 1 that Long Splices do not afford the strength of the Short Splice. However, the Long Splice causes a smaller increase in diameter. Properly tucked and well pounded down, the Long Splice will often run satisfactorily over sheaves.

If ordered from our mills, care must be taken in terminology to avoid confusion with the Long Blind Splice, listed below. In the Long Splice, strands are not divided, but are tucked back over and under in both directions.

Long Blind Splice—Sometimes called the “Transmission Splice”, the Long Blind Splice sacrifices a great deal of strength in order to preserve a constant bulge-free diameter.

The mating strands are divided in half and recombined. This introduces points of seriously reduced strength. The Long Blind Splice should never be used except where the reduced strength is acceptable.

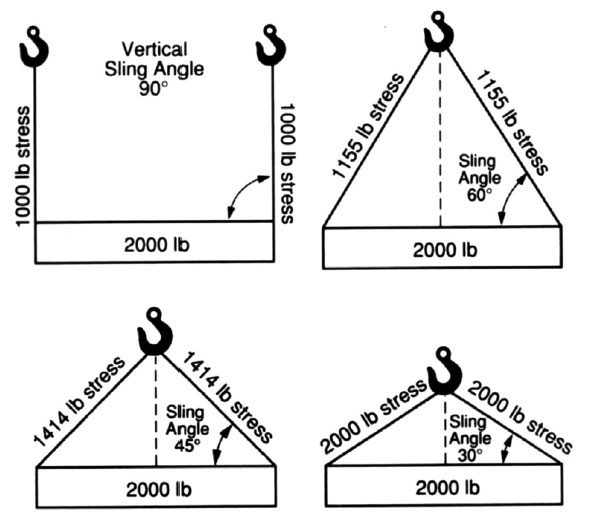

Effect of Sling Angle on Sling Load

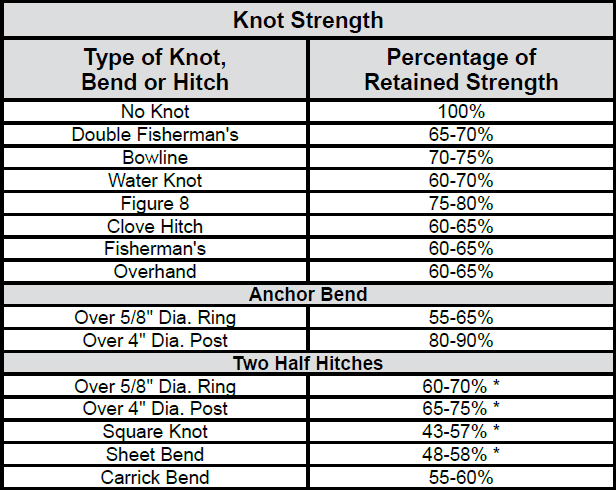

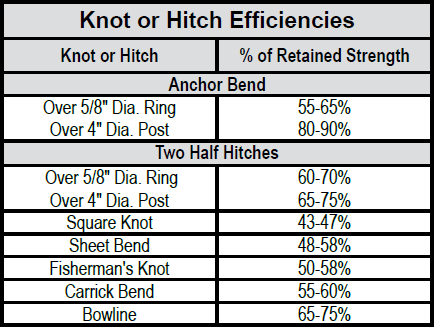

Effects of Knots and Serve Bends on Rope Strength