Are you in the market for a new chain hoist that can stand up to the most difficult tasks under the toughest conditions?

Are your current chain hoists too old, and it’s becoming more difficult/costly to repair, or something easier to use and with a higher capacity is needed to increase productivity and efficiency?

The Harrington NER 3 Phase Electric Chain Hoist may be the answer you’ve been looking for all along.

For more than 150 years, Harrington Hoists, Inc. has been providing end-users with solutions for their lifting and rigging needs, and their most popular product was designed to hold up to difficult conditions with quiet operation, and minimal vibration.

There is a two-fold benefit to the Harrington NER 3 Phase Electric Chain Hoist design, as it reduces fatigue on workers and extends the life of the product.

In this article, we’ll answer the following questions about the Harrington NER 3 Phase Electric Chain Hoist:

- What is the background/design of the Harrington NER 3 Phase Electric Chain Hoist?

- How much training is required to use the Harrington NER 3 Phase Electric Chain Hoist?

- How does a Variable Frequency Drive (VFD) help maximize productivity?

- What’s the lifecycle of the Harrington NER 3 Phase Electric Chain Hoist?

- What are the best and bad fits for the Harrington NER 3 Phase Electric Chain Hoist?

- What is the maintenance and service class for the Harrington NER 3 Phase Electric Chain Hoist?

- How difficult is it to replace Harrington NER 3 Phase Electric Chain Hoist parts that wear out?

- What technology/features does the Harrington NER 3 Phase Electric Chain Hoist offer end-users?

- What other NER hoists does Harrington make?

- How do I find replacement parts for NER hoists?

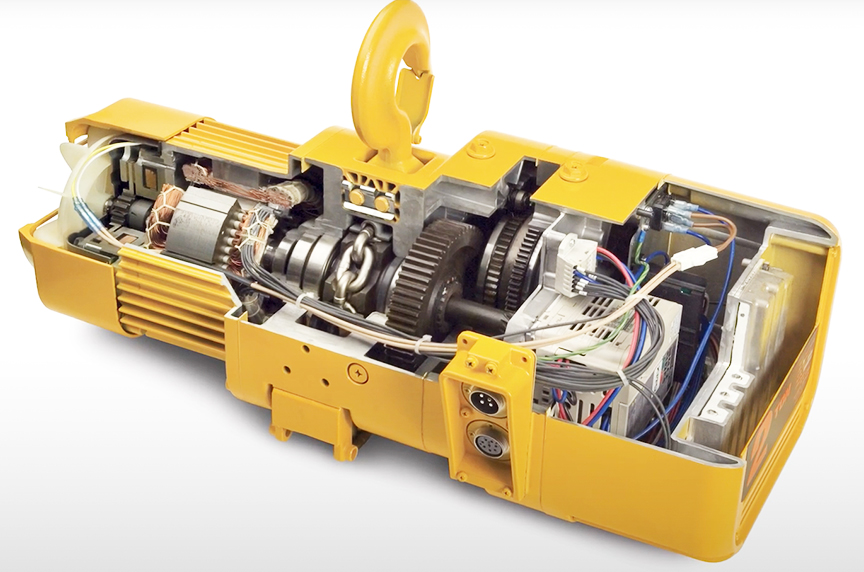

What Is the Background/Design of the Harrington NER 3 Phase Electric Chain Hoist?

For Harrington Hoists to build a solution, the company first had to identify a problem.

In 1998, Harrington rolled out its first NER hoist series, the “NER 1,” with the goal to create the most durable, efficient and end-user friendly chain hoist on the market.

Between 1998 and 2008, the market changed slightly, and end-users created a demand for dual-speed Variable Frequency Drive (VFD) hoists. In response to this demand, Harrington built and released the NER 3 Phase Electric Chain Hoist.

All of Harrington’s dual-speed hoists, including the EQ / SEQ Electric Chain Hoist, come standard with the Variable Frequency Drive. Also, Harrington worked to create a fail-safe brake.

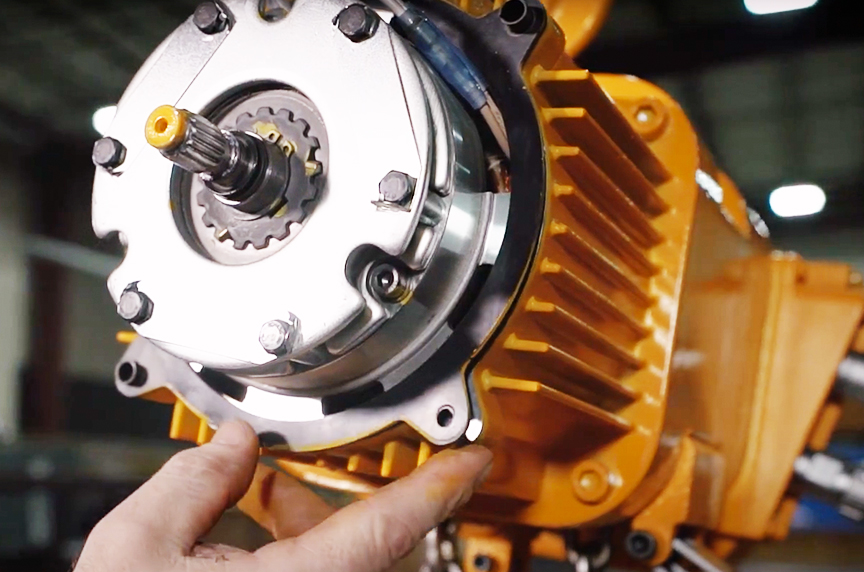

Harrington changed the braking mechanism from a pull rotor brake, which was featured in the “NER 1” series to The Guardian Smart Brake. The Guardian Smart Brake relies on an electrical current, so when there’s no current going to the hoist, the brake won’t engage.

If the power ever goes out, The Guardian Smart Brake will make sure the load is not dropped.

How Much Training is Required to Use the Harrington NER 3 Phase Electric Chain Hoist?

Harrington has learned from end-users that the NER 3 Phase Electric Chain Hoist is much easier to use than any contactor hoist.

With the Variable Frequency Drive, operating the hoist is a smooth process. Initially, when starting your lift or beginning your pull, if there’s a contactor, the hoist will jog. The VFD provides a much smoother solution and will have much softer stops and starts.

What Is the Benefit of Having a Variable Frequency Drive?

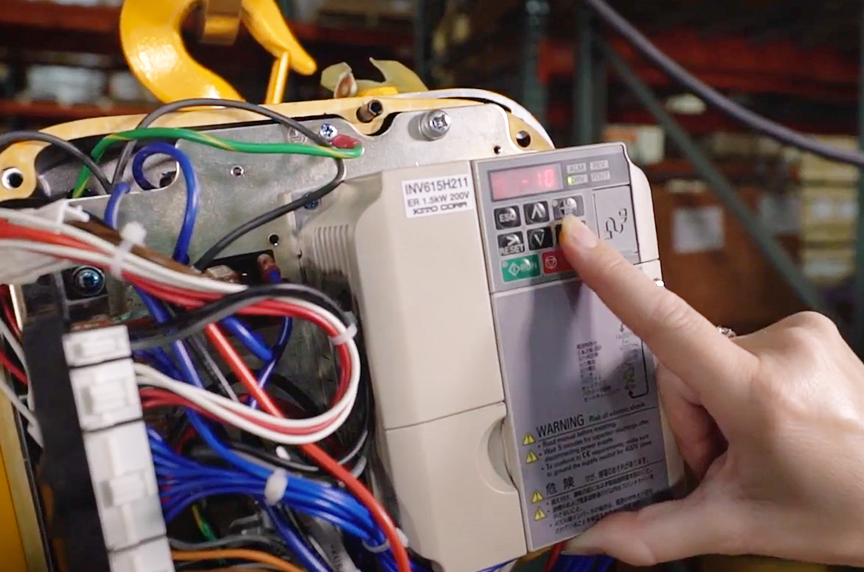

End-users can make adjustments to the speed of the VFD themselves.

As long as the workers making the adjustment have a man lift to get to the height of the hoist, they’ll be able to remove the control cover of the lifting device and make the change. The VFD is visible and easy to change.

If you’re concerned about doing something incorrect when attempting to adjust the VFD, Harrington has several videos on their YouTube channel that they recommend watching before undertaking repairs in the field.

What Is the Lifecycle of the Harrington NER 3 Phase Electric Chain Hoist?

Harrington heads to market with the goal of having their hoists last 10+ years.

A good testament to Harrington’s product designs is a number of “NER 1” hoists are still in use around the country. Harrington still manufactures parts for the “NER 1” because it’s still usable in the field.

Like the “NER 1,” the NER 3 Phase Electric Chain Hoist still is commonly used in the field.

Because the first and second series remain in use, Harrington still is unsure of the actual lifecycle of the product.

In addition to the years of service, the NER 3 Phase Electric Chain Hoist is designed to complete 2 million cycles before needing to be replaced. The average hoist’s lifespan is about 1.6 million cycles, so Harrington is pushing to get its longevity past that 2 million mark.

What Are the Best Fit Applications for the Harrington NER 3 Phase Electric Chain Hoist?

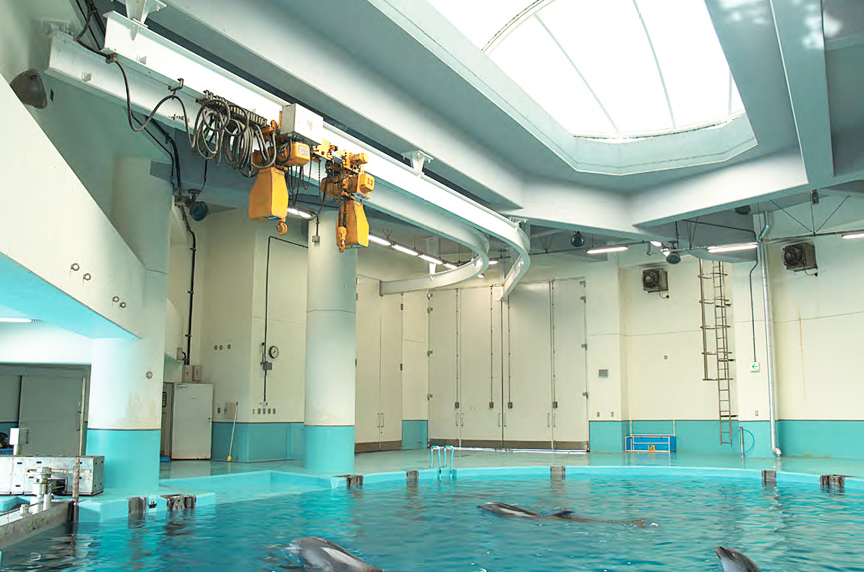

Harrington’s NER 3 Phase Electric Chain Hoists fit well inside manufacturing plants, as well as with industrial applications.

These hoists are IP55 gasket-lined, and they’re designed to handle extreme conditions as it relates to dust and water.

Environments where the Harrington NER 3 Phase Electric Chain Hoist would work well include:

- Mills

- Foundries

- Pulp manufacturers

- Paper manufacturers

- Automotive applications

For more demanding applications, the Harrington NER 3 Phase Electric Chain Hoist is indoor and outdoor-rated, so they could be used on an outdoor jib crane.

When people unfamiliar with Harrington make inquiries with the company, the product specialists ask for the absolute worst working conditions possible. Harrington wants to know what your harshest environments look like, so their representatives can understand what products would best fit your needs.

Be prepared to answer the following questions on a consultation:

- Is your operating space dirty?

- Are the working conditions dusty?

- Is your operating space wet?

- Are your hoists under constant use?

Harrington wants to place a hoist there first to show end-users how the product will operate in those adverse conditions, which develops a trust with the company and loyalty from the customer.

What Do IP Ratings Mean?

The first number refers to levels of protection from solids:

0: Not protected

1: Protected against objects up to 50 mm in diameter (i.e. equivalent to the back of the hand)

2: Protected against objects up to 12 mm in diameter (i.e. fingers or similar objects)

3: Protected against objects up to 2.5 mm in diameter (i.e. tools, thick wires)

4: Protected against objects up to 1 mm in diameter (i.e. most wires, screws)

5: Dust protected

6: Dust tight (complete protection from contact)

The second numeral addresses liquid protection:

0: Not protected

1: Protected against dripping water

2: Protected against dripping water when tilted up to 15 degrees from normal position

3: Protected against spraying water

4: Protected against splashing water

5: Protected against water projected from a nozzle

6: Protected against powerful water jet spray

7: Protected against water submersion up to 1 meter

8: Protected against submersion

By being IP55 rated, the Harrington NER 3 Phase Electric Chain Hoists are dust protected and protected against water being projected from a nozzle.

<!–[if lte IE 8]><![endif]–>

hbspt.cta.load(3336966, ’31faf022-9313-4b38-8ac8-a0743eb5eaf3′, {“region”:”na1″});

hbspt.cta.load(3336966, ’31faf022-9313-4b38-8ac8-a0743eb5eaf3′, {“region”:”na1″}); What Are Bad Fit Applications for the Harrington NER 3 Phase Electric Chain Hoist?

Saltwater Applications

Many of Harrington’s manual products are good for any saltwater application because of its work with the shipbuilding industry. The Harrington NER 3 Phase Electric Chain Hoist can be used in those applications as well because it can keep out the saltwater.

However, Harrington has found that using the NER 3 Phase Electric Chain Hoist in saltwater applications limits the life of the product, even those it outlasts many competitors’ offerings.

High Explosive Industries

Harrington doesn’t yet have a product that is explosion proof.

The NER 3 Phase Electric Chain Hoist is not an explosion-proof product.

What Is the Maintenance and Service Class for Harrington NER 3 Phase Electric Chain Hoist?

With every hoist purchased, Harrington sends end-users an owner’s manual. Every box shipped containing a Harrington product will include an owner’s manual. The owner’s manual will tell end-users how to determine the maintenance schedule for each of their products.

As the owner of the hoist, you have to figure out which of the following classifications you fall under:

- Normal Service

- Heavy Service

- Severe Service

Normal service is defined as operations with randomly distributed loads within the rated load limit or uniform loads less than 65% of the rated load limit for more than 25% of the time.

Heavy service is defined as operations within a working load limit which exceeds normal service. That is classified as hoists whose lifts exceed 65% of the rated load for more than 25% of the time or randomly distributed loads for over 25% of the time.

Severe service involves normal service and heavy service under abnormal operating conditions like weather or constant running.

Inspection Requirements

Once you determine what service classifications your hoists fall into, there are two kinds of inspections:

- Frequent inspection

- Periodic inspection

Frequent inspections are performed by an operator or other designated person at the facility:

- For normal service, frequent inspections would be needed monthly

- Under heavy service, weekly to monthly

- For severe service, daily to weekly

Periodic inspections are performed by designated persons. Harrington partners with Mazzella to provide these services. These inspections occur:

- At least yearly for normal service

- At least semiannually for heavy service

- Quarterly for severe service

If you need your hoists repaired, you can contact Mazzella, which is a Harrington repair center, or speak with Harrington directly if you’re not sure who does repairs in your area.

By tracking the serial number of the product, Harrington can determine who the customer purchased the hoist from and guide you to that distributor first. If that company doesn’t do repairs, Harrington would put you in contact with a service repair center in your area.

What Are the Unique Design Features & Technologies of the Harrington NER 3 Phase Electric Chain Hoist?

Load Capacity

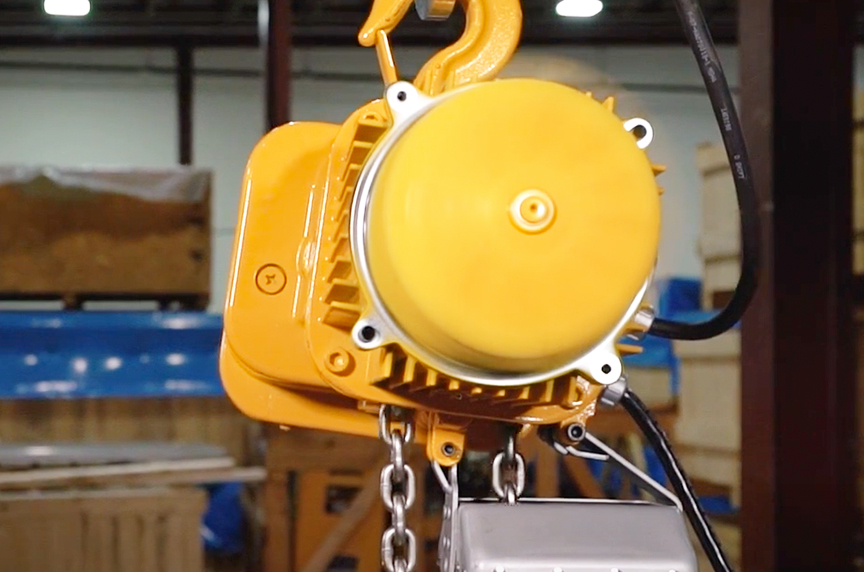

These NER 3 Phase Electric Chain Hoists are offered in 5-ton or 8-ton models in normal capacity range. Also, there is a 20-ton model for large capacity range. They are available with a hook mount, as well as a push-pull trolley, hand-geared trolley or motorized trolley.

Adjustable Speed

The dual speed VFD comes with a 12-to-one ratio as far as speed adjustment. Within that VFD, there’s an overload limiter and thermal motor protection. In a lot of our competitors’ hoists, there is a different part that could break, which would require additional repair.

Durability

Like the Harrington RY Electric Wire Rope hoist, all NER hoists are totally enclosed, fan-cooled, H4 classified, and with a 60-minute motor, which is able to achieve over 300 starts per hour. The NER 3 Phase Electric Chain Hoist has been tested and can achieve 360 starts per hour, which is the industry leader.

Pendant Controls

The plug-and-play pendant and power supply is another unique feature, especially if your pendant is damaged or not operating properly. All you have to do is unscrew the current pendant, and if you have one on the shelf or Mazzella ships a replacement, you can plug it in and be back operating with minimal downtime.

Nickel-Plated Chain

The Harrington NER 3 Phase Electric Chain Hoist features a nickel-plated chain with the smaller pitch design that adds additional strength. Also, it creates a deeper pocket groove inside the hoist, and Harrington can supply an extra pocket for some more surface contact and additional strength. Because of the smaller pitch, Harrington was able to design the hoist around the pocket wheel.

When Harrington created the NER 3 Phase Electric Chain Hoist, they made a change to a smaller chain. That gives end-users additional headroom when compared to the “NER 1” series hoists.

The nickel plated chain requires no electrification in order to have the plating adhere to the metal. Whenever you have electrification to plate the chain, it can make the chain susceptible to hydrogen embrittlement, which can make it less safe.

Cast Iron Chain Guide

The NER 3 Phase Electric Chain Hoist also features a one-piece cast iron chain guide.

The chain guide can be repaired fairly easily. You simply remove four bolts and the chain guide comes out, eliminating the need to break the hoist’s body to open.

Also, it allows a tolerance for some real-world applications. Harrington understands every hoist should be lifting in a straight up-and-down fashion. Also the company understands that in the real world, sometimes angle pulls do occur. This cast iron chain guide does allow for a certain tolerance.

Harrington doesn’t suggest you angle pull with their hoists.

10-Year Warranty

Harrington’s 10-year warranty on the Guardian Smart Brake is an industry leader.

If you have a Guardian Smart Brake that needs to be replaced within 10 years of the date of purchase, Harrington replaces it, and covers all the costs.

Smart Limit Switch

One feature Harrington offers that isn’t standard is a smart limit switch.

Rather than worrying about a new operator running the hook into the hoist, you can set the smart limit switch strictly through the pendant. It’s an easy way to program it.

You can set points for the upward motion, and also, set points on the downward travel. If you don’t want your hook running into some type of plating dipping tank, you can set it to stop right before it hits that level.

What Other Types of NER Hoists Does Harrington Manufacture?

Harrington offers multiple hoists that are under the NER model. However, they’re specific for two different industries.

Harrington has a food-grade hoist, which is available for use in the food industry, and also, in pharmaceutical facilities. The capacity runs between a ¼-ton to 2-ton. It has food-grade oil for lubricant, a white epoxy paint on the body and hooks, and stainless steel and nickel-plated components.

Also, Harrington has a model built for the entertainment industry, TNER, which stands for Theater NER. These hoists have a unique chain guide that allows it to operate with the load chain from the top. It’s IP55 rated, just like the rest of Harrington’s NER hoists.

Especially with outdoor applications, when these shows are complete, competitor products will need to be pulled apart and aired out. With Harrington’s being IP55 rated, there’s no need for that. They do have a plug-and-play voltage changer on the spot. They’re designed to fit in road cases for the entertainment reading companies.

How Do I Find Replacement Parts for NER Hoists?

The end-user cannot purchase replacement parts directly from Harrington, as it only sells products through distributors.

Mazzella is a master parts distributor for Harrington and carries many products to fulfill customer needs.

For any further questions, you can contact your local sales representatives. If you go to Harrington’s website under the “Resources” page, there is a “How To Buy” link. You can type in the first three numbers of your zip code, and it’ll pull up the information for the local territory representative.

Next Steps

The Harrington NER 3 Phase Electric Chain Hoist was engineered with the latest and most innovative technology to help improve workers’ health, as well as extend the lifecycle of the hoist itself.

That technology allows for:

- Varying load capacities based on the model in use

- Easy adjustment of speed in the Variable Frequency Drive

- Product durability

- Specially plated chain for added strength/increased surface contact

- Improved chain guiding

After reading this article, look at the chain hoists you’re using and see if the Harrington NER 3 Phase Electric Chain Hoist could improve your efficiency.

Call us at 800.362.4601 or click here if you need hoist units or parts!

<!–[if lte IE 8]><![endif]–>

hbspt.cta.load(3336966, ‘2bda6101-2ff0-4331-8f26-0b8fb85907f0’, {“region”:”na1″});

hbspt.cta.load(3336966, ‘2bda6101-2ff0-4331-8f26-0b8fb85907f0’, {“region”:”na1″});

❯ Hoists & Hoist Parts

We are your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications. We are also one of the largest authorized stocking master parts depots for Columbus McKinnon (CM) Companies and Harrington.

Copyright 2021. Mazzella Companies.