5-5 | Best Practices for Maintaining High Performance Roundslings

<p>The best way to help extend the life of a high performance roundsling, and help to ensure that it stays in service, is to properly maintain it during and in-between each use. Inspections are easier to perform—and probably more thorough—when slings are easily accessible and organized, kept off of the ground, and stored in a cool and dry environment.</p>

The best way to help extend the life of a high performance roundsling, and help to ensure that it stays in service, is to properly maintain it during and in-between each use. Inspections are easier to perform—and probably more thorough—when slings are easily accessible and organized, kept off of the ground, and stored in a cool and dry environment.

Hang your slings or keep them in a designated locker or rigging box where they are off of the ground and will not be subjected to mechanical damage, corrosive action, moisture, or extreme temperatures.

Temperature

Some synthetic yarns do not retain their published breaking strength above 140°F (60°C). The high performance roundsling manufacturer should be consulted for the temperature range of the roundsling selected for use.

Chemically Active Environments

The strength of high performance roundslings, and their fittings, may be degraded by chemically active environments. This includes exposure to chemicals in the form of solids, liquids, gases, vapors, or fumes. The sling manufacturer or Qualified Person should be consulted before slings are used in chemically active environments.

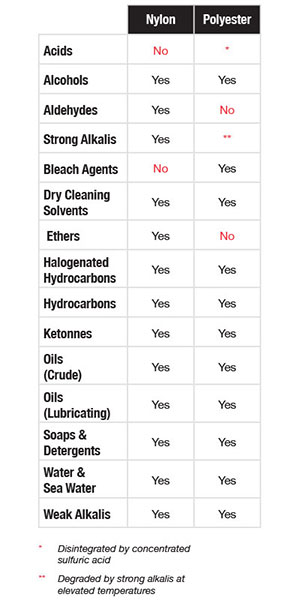

Polyester and nylon webbing materials have different chemical resistance properties. Please refer to the chart below for guidelines on polyester or nylon roundslings in specific chemically-active environments.

Sunlight and Ultraviolet Light

The strength of high performance roundslings is degraded by exposure to sunlight and ultraviolet light. The sling manufacturer or a Qualified Person should be consulted for additional retirement or inspection requirements.

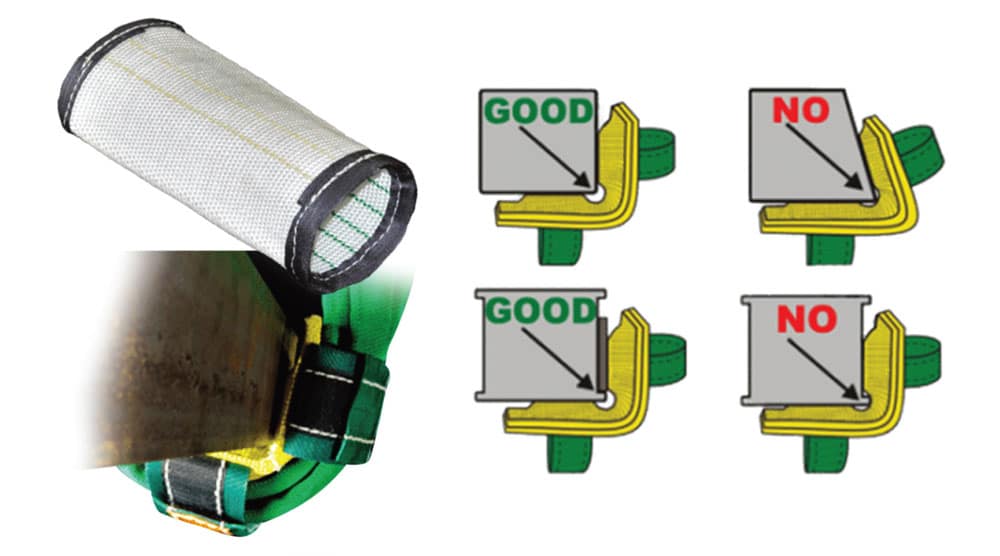

Edge and Cut Protection

Synthetic lifting slings are most susceptible to cuts, rips, abrasion, and tears. Corner protectors, wear pads, or edge guards should be used to protect roundslings against abrasion and cuts when lifting materials with edges. Edge protection and cut protection should be used on all edges and corners—even the ones that aren’t load-bearing surfaces.

Additional material, stitching, finishing, wear pads, or coatings can also be added to high performance roundslings during the manufacturing process to help improve the durability of the sling.

Keep Your Slings Clean

Continual exposure to dust, dirt, and moisture can degrade the materials over time and shorten the life expectancy of the product. Wipe grease or oil off of your slings and try to keep them clean of dirt, or other particulates which can break down the sling material over time.

Please note that synthetic slings should never be cleaned in a solvent tank used to degrease other equipment or machined parts. The chemicals used in a solvent solution can degrade the nylon or polyester fibers over time, which will affect the integrity of that lifting sling.