Description

Advantages of Bolted Ladle Hooks:

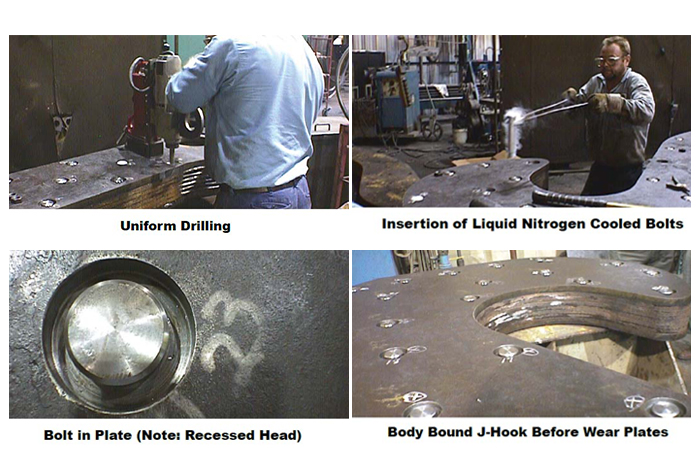

- Body bound high-strength shoulder bolts are utilized in place of the current practice of rivets. The quantity of bolts meets the same requirements as rivets per AISE Technical Report No. 7.

- The material and strength of the bolts can be compared to rivets as follows: Bolts—AISI 1045, Ultimate = 86,000 psi min., Yield = 54,000 psi min. Rivets—ASTM A31, Grade A, Ultimate = 45,000 psi min., Yield = 23,000 psi min.

- Torqued high-strength bolts pull laminated plates tighter together than the existing practice of rivet installation.

- Body bound bolts do not allow shifting between plates. By comparison, holes for rivets are 1/16″ greater in diameter than the nominal diameter of the rivet.

- Reuse of existing riveted ladle hook plates can be performed by installing larger body bound bolts sized for each specific application.

- Dismantling and subsequent repair of bolted ladle hooks is much easier than for riveted hooks, reducing the overall cost.

- Current experience with bolted ladle hooks has resulted in an expected service life increase of 4 to 5 times that of riveted hooks.