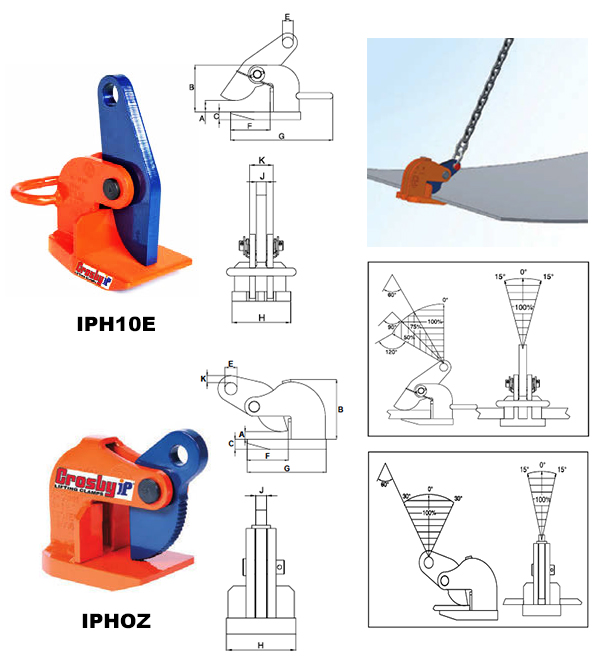

Description

For Horizontal Lifting and Transfer

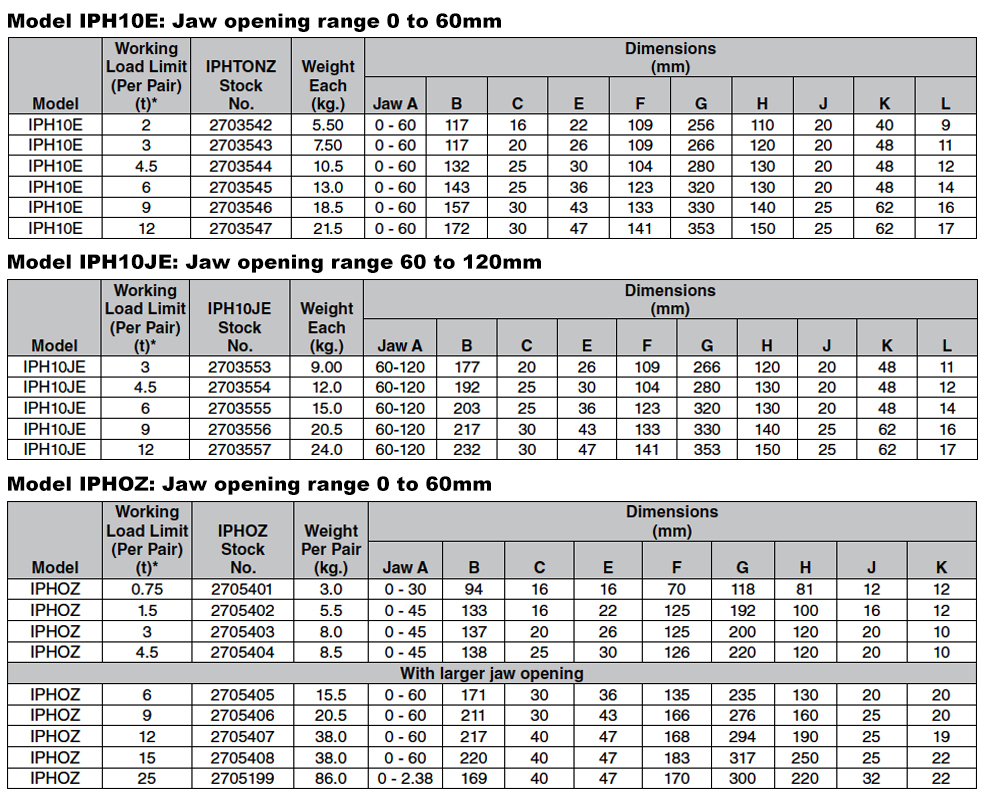

- Available in capacities of .75 thru 25 metric tons.

- Wide variety of jaw openings available: 0 to 120mm.

- Welded alloy steel body for strength and smaller size. Forged alloy components, where required.

- Equipped with handle for easy placement.

- Individually Proof Tested to 2 times the Working Load Limit with certification.

- Company name (CrosbyIP), logo, Working Load Limit and jaw opening permanently stamped on body.

- Each product is individually serialized, with the serial number and Proof Load test date stamped on body. Serial number is included on the test certificate with maintenance and warranty logbook.

- Maintenance replacement parts are available.

- Manufactured by a ISO 9001 facility.

- All sizes are RFID EQUIPPED.

* Design Factor based on EN 13155 and ASME B30.20.

Call Mazzella for your clamp repair or inspection needs!

All brands and capacities … including, but not limited to Renfroe, The Crosby Group, Campbell, CM, SuperClamp, and Terrier. Contact your local Lifting Specialist to arrange for pick-up of your lifting clamps for inspection and/or repair!