Description

Every McKissick® Roll-ForgedTM sheave starts as a single piece of AISI C-1035 carbon steel plate.

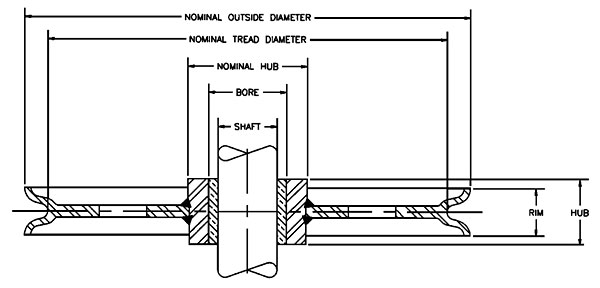

Utilizing a “time proven” proprietary roll forging process that adds extra strength to the critical groove section, the sheave is formed from a precision flame cut blank. The hub is then pressed into place with complete metal-to-metal contact and secured with a deep penetrating weld to ensure proper fit and longer life.

Before the McKissick® name is added, each sheave is thoroughly inspected to meet applicable industry and Crosby® quality standards.

Connect with our specialist today! We will help you answer any questions you may have and assist you in completing your project.