Description

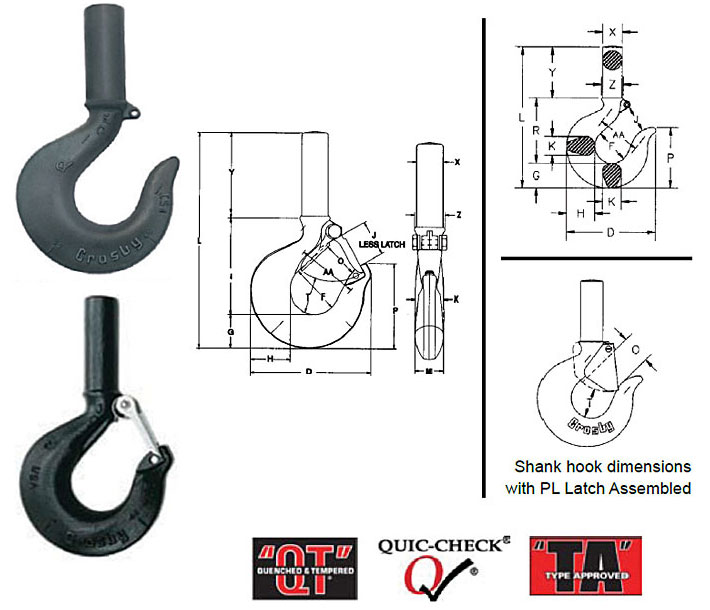

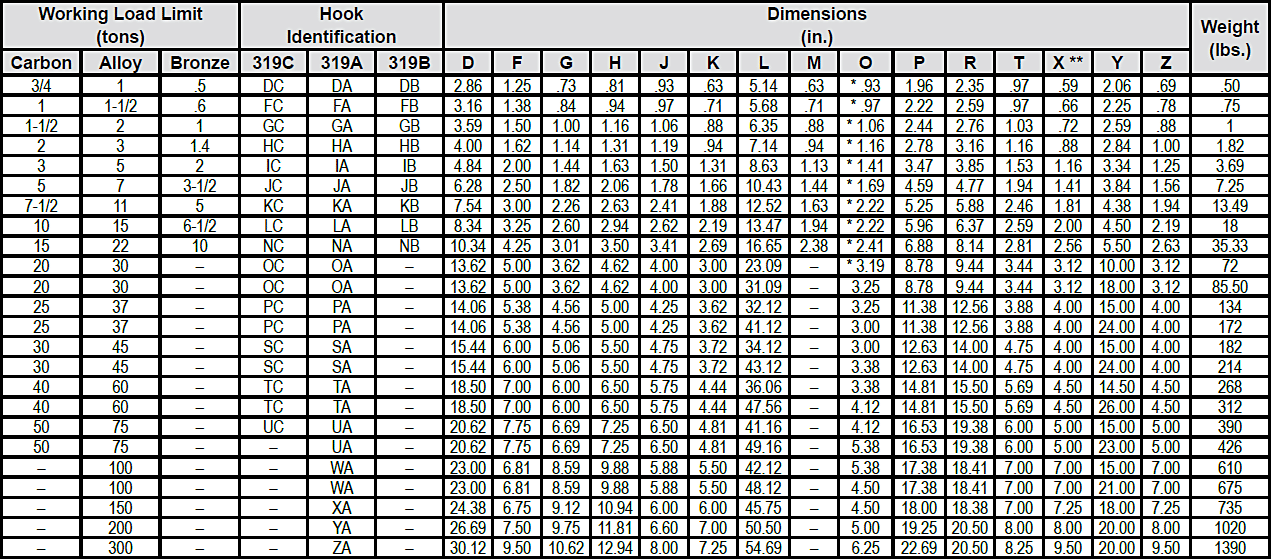

* Dimensions shown are for S-4320 Latch kits. Dimensions for sizes 20 ton carbon and larger are for PL Latch Kits.

** Dimension before machining (as forged).

Note: Proof load is 2 times Working Load Limit. All carbon hooks—average straightening load (ultimate load) is 5 times Working Load Limit. Alloy eye hooks 1 ton through 22 ton—average straightening load (ultimate load) is 5 times Working Load Limit. Alloy eye hooks 30 tons through 60 tons—average straightening load (ultimate load) is 4.5 times Working Load Limit. All Alloy shank hooks- average straightening load (ultimate load) is 4.5 times the Working Load Limit. All Bronze hooks—average straightening load (ultimate load) is 4 times Working Load Limit.