Description

For Corrosive or High Temperature Applications

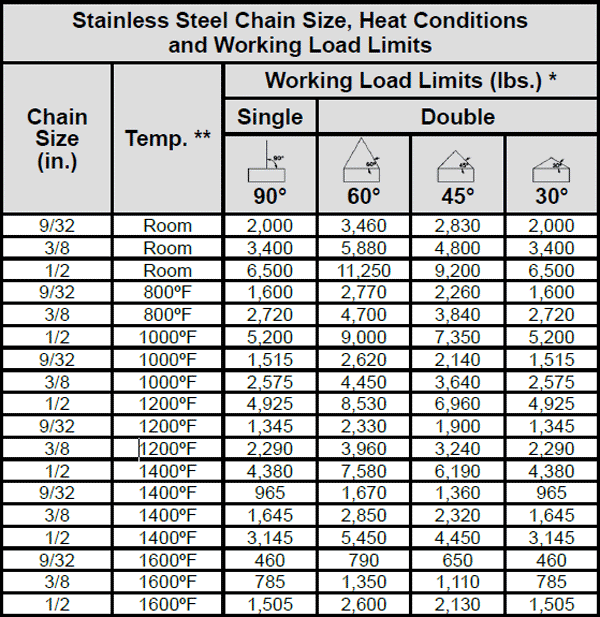

Note: Although the only chain recommended by NACM, ASME and OSHA for overhead lifting is Alloy Chain (Grade 63, Grade 80 and Grade 100), there are occasions when use of Non-Alloy chain with a lower working load limit will provide superior longevity in service. Type 347 Stainless Steel Chain is the preferred lifting chain in some corrosive and elevated temperature environments where the effects of corrosion or extreme heat can have an effect on Grade 63, Grade 80 and Grade 100 chain.

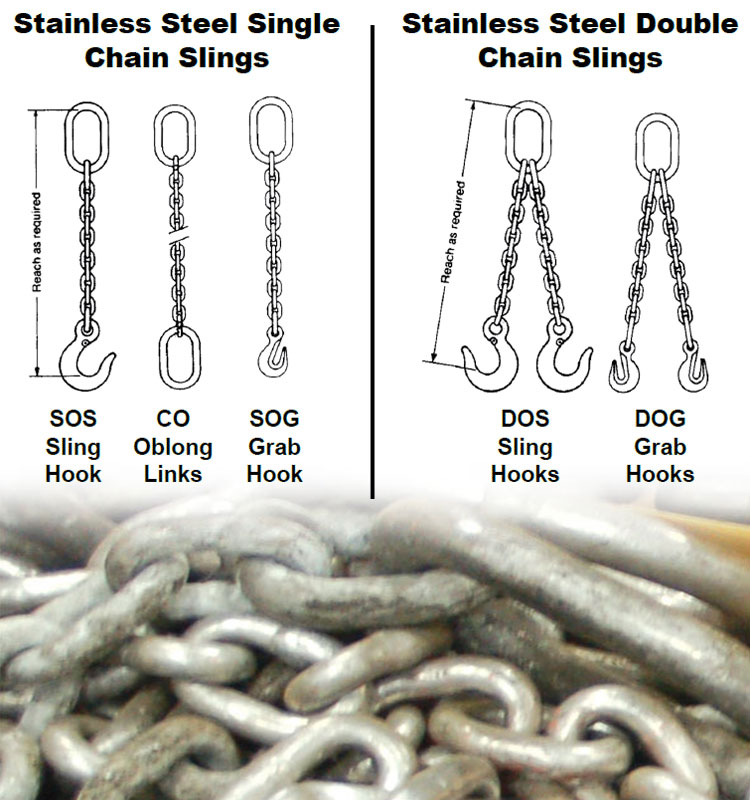

Type 347 chain is available in running lengths, as well as single, double, triple and quad branch sling chains. Sling hooks and grab hooks are available. Chain is embossed SSTL.

Corrosion Resistance:

Good: Food service, sterilizing solutions, most organic chemicals, many inorganic chemicals, dye vats, nitric acid, fresh and salt water, weak sulfuric acid

Poor: Strong sulfuric acid, hydrochloric acid, chloride salts, halogens (fluorine, bromine, iodine and chlorine)

High Temperature Properties

Retains considerable strength at temperatures up to 1600°F. The maximum recommended temperature for continuous service is 1000°F and for intermittent service 1600°F.

* WARNING: Working load limit is not to be exceeded.

** For long-term exposure at temperatures over 1000º F., creep strength or stress-rupture strength may determine the safe load limits.

For triple branch and quad branch working load limits, multiply the double branch values by 1-1/2.