Wire Rope End Terminations: Sockets, Wire Rope Clips, and Splices

Are you confused about the difference between a swaged socket and a spelter socket? Need to know what type of wire rope clips you should be using? In this article, we walk you through the different types of fittings and splices used to terminate the end of a wire rope cable or sling assembly.

As a rigger or end-user of wire rope, it’s important to understand the types of terminations, or treatments, that can be used at the ends of a length of wire rope. These terminations are usually made by forming an eye or attaching a fitting, and are designed to be a permanent end termination on the wire rope where it connects to the load.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

In this article, we’ll explain what some of the following terms mean and how the can be used to terminate the end of a wire rope cable:

- Wire rope sockets—spelter sockets, swaged sockets, and wedge sockets

- Wire rope clips—U-bolt wire rope clips and double saddle wire rope clips

- Eye splices—mechanical (Flemish) and hand-tucked splices

- Wire rope end termination efficiencies

When you understand the construction and specifications of the wire rope you need, as well as the right type of end termination you need, you’ll be able to select the best performing and longest-lasting wire rope for the job at hand.

Types of Wire Rope End Terminations

There are essentially two techniques that can be used to create a termination on a length of wire rope or cable:

- You can form an eye, or loop, in the wire rope

- You can attach a fitting to the end of the wire rope

Eyes, or loops, can be created at one end of a length of wire rope by using a mechanical splice with a swaged sleeve, a hand-tucked splice, or wire rope clips.

Fittings can be secured to wire rope by swaging, by pouring molten zinc or a resin that bonds to the wires, or by using a wedging arrangement.

Types of Wire Rope Sockets

Socketing is the process of attaching a termination fitting to the end of a wire rope cable.

A socket can be attached to the end of a wire rope cable using a variety of different methods, including:

- Hydraulic pressure

- Pouring molten or epoxy material

- Using a mechanical wedge

When considering a poured or a swaged socket, note that both types are available in either an open or closed design.

Open Sockets vs. Closed Sockets

An open socket has a pin or bolt that can attach the wire rope assembly to another type of fitting, or possibly a hook block.

A closed socket fitting has a hole in it that is designed to accept a pin or bolt

Swaged Sockets

A swaged socket is applied to the end of a wire rope cable and is then forced into place using special dies and a hydraulic machine called a swager. When properly applied with the correct sized fitting, swaged sockets have an efficiency rating of 100% of the breaking strength of the rope.

Swaged fittings are more resistant to wire fatigue at the point where the cable and socket come together.

However, swaged sockets are not recommended for use on fiber core or lang lay wire rope cables.

Spelter / Poured Sockets

A poured socket, commonly referred to as a spelter socket, attaches a termination fitting onto the end of a wire rope cable by pouring molten zinc or resin into a socket that then hardens and holds the fitting onto the end of the cable.

Poured sockets are one of the most efficient types of wire rope end attachments—delivering 100% efficiency of rope breaking strength.

Due to the rigidity of this type of termination, the wires of the rope are subject to fatigue where the wires enter the socket, if the poured socket is subject to constant vibration.

Wedge Sockets

Wedge sockets secure the rope to the end attachment by passing it around a grooved, wedge-shaped piece of steel and pulling it down under load into the bowl of the fixture.

Wedge sockets are popular because they can be installed in field and adjusted in field – providing 80% efficiency of rope breaking strength. Wedge sockets are popular in applications where the wire rope may be subjected to abuse and abrasion—particularly in construction and mining applications.

Wedge sockets allow the end-user to adjust the length of a wire rope cable if exact and matched sets of crane cables are not available.

Wire Rope Clips

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80% efficiency of the rope breaking strength.

However, the use of wire rope clips is heavily regulated by ASME B30.26 Rigging Hardware. When using wire rope clips, the end user must account for the following:

- When using U-bolt wire rope clips, the saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—NEVER SADDLE A DEAD HORSE!

- Use at least the minimum number of clips as recommended by the manufacturer or a Qualified Person

- All wire rope clips shall be tightened to the torque recommendations of the manufacturer or a Qualified Person

- After installation, the connection shall be loaded to at least the expected working load. After unloading, the wire rope clips shall be re-tightened to the torque specifications of the manufacturer or a Qualified Person.

U-Bolt Wire Rope Clips

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

Forged Wire Rope Clips

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable Wire Rope Clips

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Double Saddle Wire Rope Clips

Double saddle wire rope clips consist of two saddles, each with a leg, and two nuts—one used on the top and one on the bottom. Double saddle wire rope clips can be used in either direction, so they take the guesswork out during installation when applying to the live end and the dead end of a piece of wire rope.

Wire Rope Splices

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound and then the wire is bent around, and the unwrapped strands are then weaved back into the wire rope to form an eye.

There are two types of splices that can be used to form an eye on the end of a wire rope:

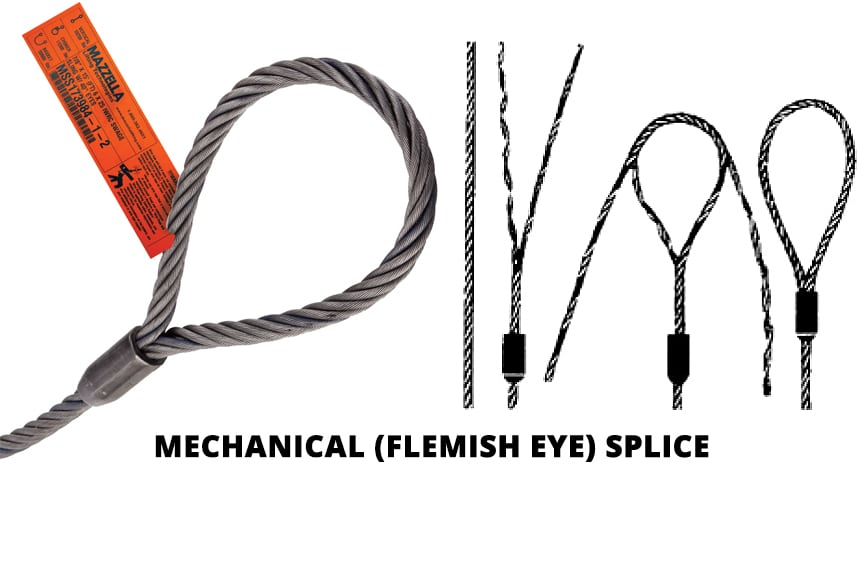

Mechanical (Flemish) Splice

A Flemish eye splice is created when the wire rope is opened, and the strands are laid out into two parts. The two strands are looped in opposite directions and then laid back together—forming an eye, or loop, at one end of the wire rope cable. The strands are then rolled back around the rope body and a metal sleeve fitting is slipped over the splice and swaged using hydraulic machinery. This splicing method provides the most efficient use of rope capacity and is highly economical.

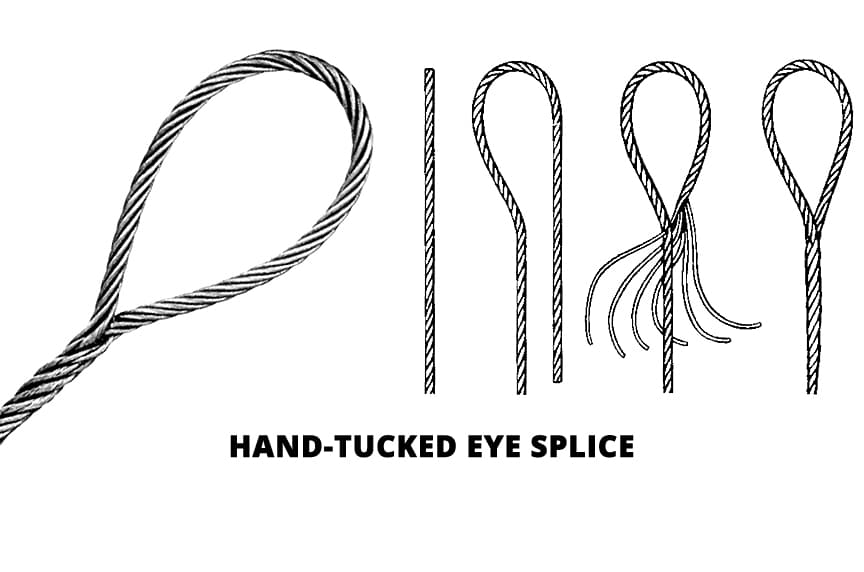

Hand Tucked Splice

A hand tucked splice is formed when the shorter “dead” end is tucked into the longer “live” end of the wire rope—forming an eye. These types of splices allow for easy inspection of the wire rope wires and strands.

Use of Thimbles in Eyes of Wire Rope

When the end of a rope is turned back and formed into an eye, a thimble is often used to keep the shape of the eye, prevent the rope from being crushed, and keep the rope from being bent at a diameter smaller than the rope manufacturer’s recommendations.

Efficiencies of Wire Rope End Terminations

The table below will explain the efficiencies of the different types of wire rope end terminations for both independent wire rope core (IWRC) and fiber core (FC) wire rope configurations. Rope efficiency is described as the ratio of a wire rope’s actual breaking strength and the aggregate strength of all individual wires tested separately—usually expressed as a percentage.

| IWRC | FC | |

| Hand-Tucked Splices | 80–90% | 80–90% |

| Mechanical Splices | 90–95% | 90–92.5% |

| Swaged Steel Fittings | 95–100% | 90–95% |

| Poured (Spelter) Sockets* | 100% | 100% |

| Wire Rope Clips** | 80% | 80% |

| Wedge Sockets | 75–90% | 75–90% |

*Spelter sockets in smaller rope sizes (usually less than 7/16”) may not always develop 100% efficiency and are not recommended by some rope manufacturers.

**When properly applied and maintained per clip manufacturer’s recommendations.

Wrapping it Up

When you need to order a replacement wire rope, understanding the right type of end termination will help to make sure you get a direct replacement rope so you can get your project back on track. We hope this article gives you a better understanding of terms related to sockets, wire rope clips, and eye splices and that you understand what type of end termination may be best for your application.

At Mazzella, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

If you’re looking for a standard or custom-specified wire rope or cable assembly for your next project, contact a Lifting Specialist at a Mazzella location near you.

Wire Rope Assemblies & End Fittings

Are you looking for a custom assembly or end fitting for your wire rope? We can produce any assembly to fit your specifications precisely.

Call us at 800.362.4601 or click here if you need wire rope assemblies or end fittings!

Copyright 2019. Mazzella Companies.