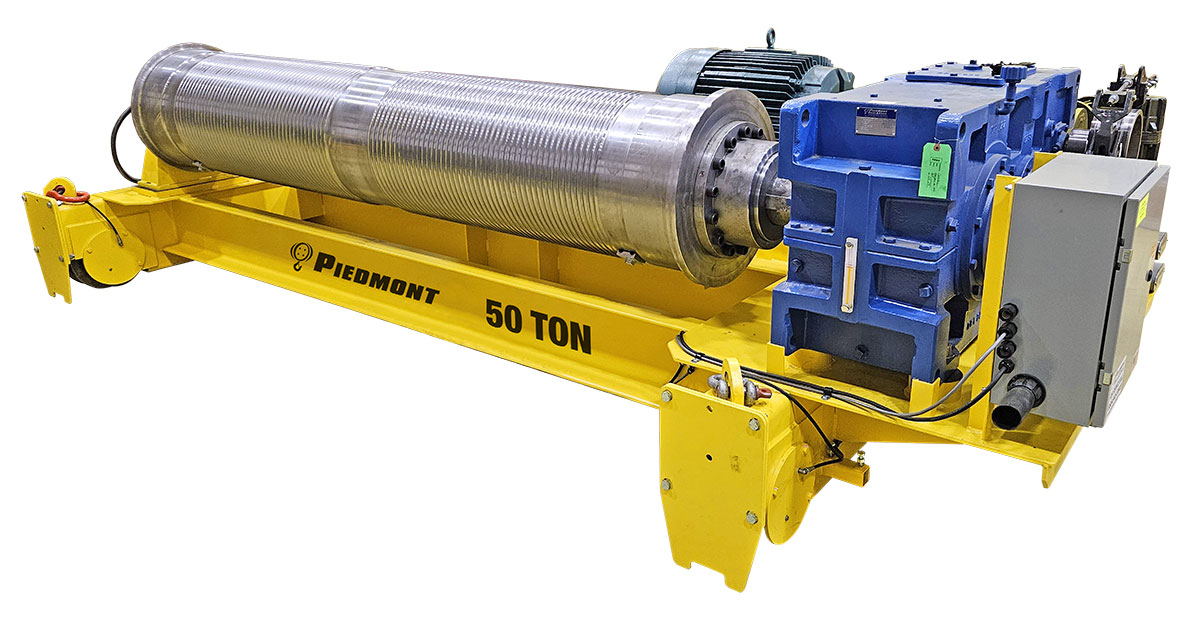

CE Custom Engineered Built-Up Hoists

Capacity: 5 tons to 250 tons

Service Class: CMAA Class D standard. Available through CMAA Class F

Industries: Heavy manufacturing, steel service, hot metal, aerospace, defense, foundries, paper mills

Trolley Frame: One-piece welded structure with load girts, heavily ribbed and gusseted to resist vertical, lateral, and torsion stresses. All areas which do not require openings for operation are fully decked, making all equipment readily accessible from the top of trolley. Lifting lugs are also provided.

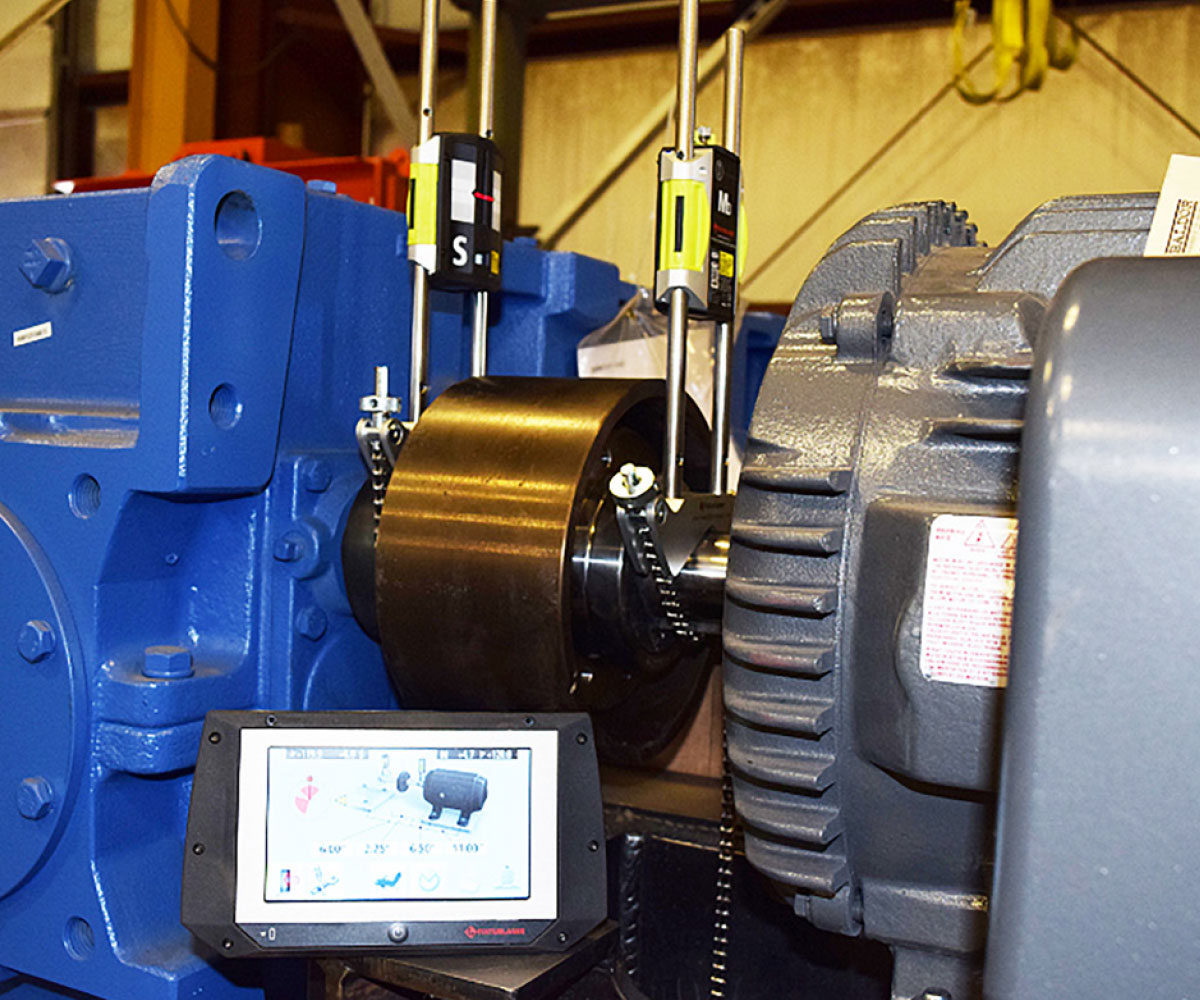

Hoist Reducer: High quality cast iron (steel available) gear case is foot-mounted and horizontally split. Helical gears are alloy steel, carburized to 60Rc, then finished ground to meet AGMA class 12 standards. Shafting is heat-treated, high-alloy steel mounted on spherical roller bearings. Splash lubricated and provided with dual lip oil seals. Other features include oil level dipstick, inspection access cover, air breather, magnetic drain plug, and lifting lug.

Hoist Motor: Standard motor is a foot-mounted vector motor, continuous duty rating with Class H insulation, thermostats, and encoder. Fully flexible geared coupling used at motor output shaft. Lifting eye and easily accessible junction box are also provided.

Hoist Brake: Foot-mounted shoe brake is standard. Disc, hydraulic disc, and multiple brakes are optional.

Hoist Drum: Welded steel construction. 1/2 depth grooving and fleet angles designed to minimize wire rope wear and extend rope life. Left-hand and right-hand grooving for true vertical lift.

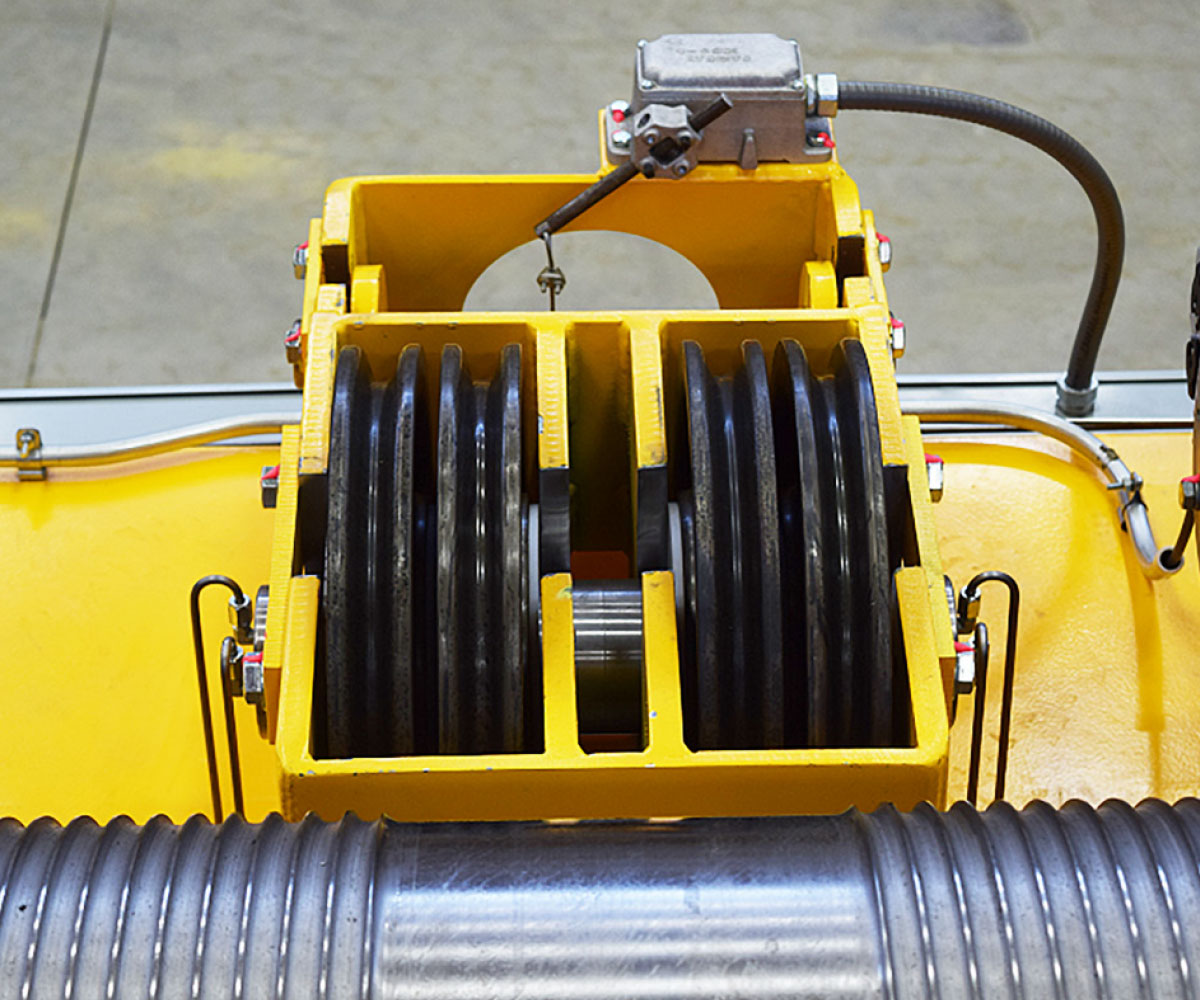

Upper Sheaves: Located above trolley deck for easy access. Equipped with anti-friction bearings. Running sheaves offer minimum 20:1 cable ratio. Idler sheave ratio is a minimum 12:1.

Wire Rope: 6×37 IWRC EIP steel – designed for hoisting service. Sized for a 5:1 safety factor.

Lower Block: Heavy one-piece steel weldment. Sheaves are enclosed and fully guarded for added operator safety. Forged alloy or cabon steel hook is mounted on a roller thrust bearing for 360° rotation. A spring-loaded safety latch is also provided.

Limit Switches: Each hoist is provided with a weight-operated upper limit and a rotary upper-geared and lower-geared limit switch. Overload protection is standard on all Flux Vector applications.

Trolley Trucks: Rotating axle wheels supported on spherical roller bearings mounted in modified MCB housings. Fabricated structural box sections and accurately machined for trouble-free operation. Double flanged wheels are C1045 steel and flame-hardened to 425 BHN available up to 600 BHN. Lubrication fittings, rail sweeps, and bumpers are provided.

Trolley Drive: The drive consists of an integral brake motor mounted on a helical reducer. The drive unit is shaft-mounted on the drive axles and is splash-lubricated in an oil-tight gear case. Standard features include continuous duty, Class F insulation, and motor thermostats.

Accessories: Auxiliary hoists, flame-hardened drums and sheaves, centralized lube systems, outdoor and hazardous locations, weigh systems, power limit switches, over wrap limits, base-mount design, stainless wire rope, rotating lower blocks, anti-sway reeving, operator cabs, mill-duty brakes, hook rotation blocks, hydraulic bumpers, custom-forged hooks, hand railings, coupling guards, tie-off points (fall protection).