Fall Protection for Roofers: Systems, OSHA Regulations, & Best Fits

Are you looking for a better fall protection system to make working conditions safer for your roofers? Here, we explain different types and configurations of fall protection systems, OSHA regulations, best fit applications, and common problems for end-users.

Going home safely at the end of every workday is something people who don’t work in the construction or roofing businesses can take for granted. But for those working at height, focusing on safety and fall protection are very important parts of every-day life.

Working at height adds unique challenges and increased levels of danger for construction crews and roofers, and there needs to be safety systems in place that will help protect them should a fall occur.

Fall protection is important for roofers, who not only work at height, but do so often while working at steep angles where one slip could prove catastrophic.

There are different types of fall protection systems available for roofers, but with each, the goal remains the same: keeping everyone safe so they can go home at the end of every shift.

In this article, you will learn about several fall protection systems for roofers, including:

- Components

- Configurations

- Best practices

- Best fit applications

- Common problems you might encounter

- OSHA regulations and enforcement

Fall Protection Kits

Simple Compliance

Think of this option as fall protection made easy.

You have a standard fall protection kit in a five-gallon bucket or gym bag, which in addition to fall protection companies, can be purchased at major retailers for around $100, including:

- Home Depot

- Lowes

- Amazon.com

The kits fulfill the needs of the ABC’s of fall protection (Anchorage Point/Body Wear/Connecting Devices).

If a bucket is too cumbersome to take on a job site or takes up too much space in your truck, Mazzella and other outlets offer kits that come in soft bags that are of similar size or smaller than your typical gym bag.

What is Included?

Typically, fall protection kits include a:

- Full body harness

- Reusable metal anchor

- Lanyard

- Double Lock Hook

- Rope grab

A full-body multi-dynamic harness is standard for roofing fall protection kits. They’re lightweight, especially if you don’t want to carry the added weight from padding. If you’re working in a warm climate, and are concerned about the effects heat can have on your health and safety, you may want a harness with smaller amounts of padding.

Also, you could upgrade the harness if you wanted one with more padding, or if you need an extra-large or extra-small size.

A vertical lifeline assembly comes with a 25’ or 50’ rope. There are some larger ones in the market that go up to 100’, but your standard kits run a 25’ or 50’ rope. The rope features a snap hook on one end and a knob on the other, so you can adjust it as needed.

The rope grab comes preinstalled on the system, and it attaches to the back D-ring of your harness. You can work your way through the ropes, and if you should fall, it will arrest your fall. The rope grab does have a shock pack on it, which is your energy-absorption device. In the case of a fall, it will deploy and elongate out of the shock pack.

Proper Fit is Everything

The harness that comes in these kits are the standard small, medium, and large universal. However, fall protection kit producing companies offer harnesses in XL, 2XL, and 3XL.

You want to make sure your workers are properly fitted. It is incorrect to assume everyone can fit in the same harness. You’ve got to make sure the harnesses are properly fitted because if you do take a fall and the fit is improper, it can lead to serious injuries, and/or death.

Removal from Service

These kits are one-use systems, and you’ll want to remove it from service if it is worn during a fall. The full-body harness will have load indicators on them, and those will likely be tripped during a fall.

With the majority of these components, you’ll want to remove them from service. With some of the larger systems, you may not have to remove all components from service. It just may require a competent person inspection, but the products in the kits will need to be removed from service.

Calculating Fall Distance

Occupational Safety and Health Administration (OSHA) requires that potential free fall distances will never exceed 6’ (1.8 m) when using personal fall protection. Careful consideration must be given to the way that a fall arrest system is selected and rigged so that a 6’ fall distance is not exceeded. A qualified person must select the components, materials, anchorage and anchorage connects to match the system application, the work being done, workplace hazards, and the environment.

You should always follow the manufacturer’s recommendations when connecting harnesses, lanyards, or retractables so the deceleration distance and elongation are accounted for when calculating total fall distance.

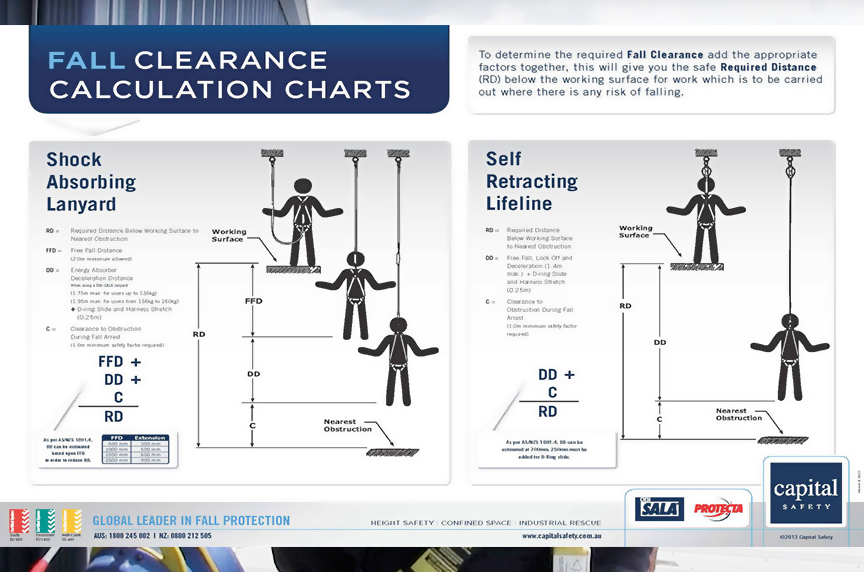

Total fall distance is the total distance of a free fall, plus the additional distance encountered during deceleration. When calculating total fall distance for an employee working at height, all of the following factors must be considered:

- Length of lanyard/Self-retracting lifeline – The actual measured length of the lanyard or retractable device that the worker uses to connect their harness to an anchorage point.

- Deceleration/Free fall distance – OSHA’s maximum allowable deceleration distance is 3.5 feet, which accounts for dynamic elongation of the energy absorber.

- Height of worker – The worker’s height is another critical factor that must be accounted for to consider the total fall distance.

- Distance from the worker’s feet to the harness D-Ring – Accounts for how much the harness will stretch when supporting the worker.

- Safety factor – Allow for an additional safety factor of 3’ (1 m) below a fallen worker’s feet.

Which system you use is job site specific. You have to create a safety plan by looking at the job site, understanding how high you’re working and the equipment you’re using before choosing an appropriate fall protection system.

Kit systems are designed more for fall restraint than fall protection, so if that system is set up the right way, it’s not going to allow you to come off the roof. If you fall, it’s going to lock up, and you’re going to fall on the roof surface, not off the side.

***You shouldn’t have enough rope out where you create a swing fall or you freefall off the roof. Also, you should never tie off to an end that allows you to go past the edge of the roof.

Counterweight Fall Protection Systems

For customers who don’t want penetration on their roofs because they’re worried about it being sealed and leaking, especially if it’s a bonded roof, there are non-penetrating counterweight fall protection systems.

These systems are used for flatter roofs, and there’s also counter-weighted skid carts that act as a tie-off point. They’re made specifically for people to tie off to, and sometimes, have multiple tie-off points. It can be set up for fall restraint or fall protection.

The counterweight systems can be temporary setups. If you have an HVAC (Heating, Ventilation, and Air Conditioning) system that you’re going to work on, and it’s close to the edge of the roof, a counter-weighted guard railing can be put up between the unit and the edge of the roof.

The guardrail system can be moved around on the roof from application to application.

Mazzella FHS Fall Protection experts encourage customers to go over those job site details ahead of time so they can help you find the system that best addresses your needs.

Permanent / Fixed Fall Protection Systems

If you need more substantial fall protection, you may need a permanent rooftop system. These permanent systems are designed by a professional engineer, and a trained crew will install them onto the roof surface.

There is a horizontal lifeline that can be attached to the roof surface and allow numerous workers to tie off.

Mobile Fall Protection Systems

If you don’t want to make adjustments to your roof surface, mobile fall protection could be your solution.

Malta Dynamics produces a device known as “The Grabber,” which is a non-penetrating system generally placed on the ground instead of the roof surface. It’s a mobile fall protection system unit that can boom 34’ into the air and provide tie-off for up to five workers depending on the model.

If you’re working on a roof, you would put it over the gutters and not boom it over the top of the center of the roof because your fall hazard is off the roof.

If your roofers are working on the edge, and they take a fall off the roof, you don’t have to worry about the lifeline coming in contact with an edge.

Mobile fall protection systems are both convenient and safe. These systems get trailered onto your job site with a pick-up truck and are set up in minutes.

The system’s construction and design allow for some give depending on the weight you drop on it, but with The Grabber, a Class B self-retracting lifeline is required. The maximum arresting force is 900lbs.

Training

Basic Systems

Typically, on most of these systems, someone can receive the proper training in one hour.

In large groups, Mazzella FHS Fall Protection specialists will require more time because they’re teaching how to don the harness properly and fit-testing the workers who will be using the equipment.

Fall Protection Kits

With the kit systems, on-site training isn’t necessary because it is built for you to buy off the shelf, have on your person, and then, know how to use it just by going through the owner’s manual or reviewing an online video.

Training sessions for the roofing kits require you to learn:

- How to conduct the pre-use inspection

- Proper donning of the harness

- Proper usage

The Grabber

When Malta Dynamics trains end-users on The Grabber, they assume the end-users know fall protection, are properly trained to use the harness, and have at least some of the background knowledge required to properly use the product.

This training is more equipment-specific.

Malta Dynamics uses a classroom session to go over a PowerPoint presentation, and then, there is hands-on training where end-users will run the boom up and down, have workers tie off to it and show them best practices and best uses.

The typical length of a class is 2-3 hours depending on the size of the group.

Best Fit Applications

Fall Protection Kits

When you and a number of workers are operating on a small roof, and it’s got a peak or pitch, you want to use a roofing kit instead of a mobile fall protection system. Mobile fall protection systems can be used for residential construction, but based on our fall protection experts, it’s designed more for commercial use.

A lot of general contractors who are working on warehouses or big remodels of buildings should look at a mobile fall protection system like The Grabber, instead of a kit system.

The best use for the kit system is as fall restraint. If you know the roof’s edge is 10’ from the anchor point, you need to have your rope grab adjusted to 6’ or 7’ so you physically can’t fall over the edge.

According to OSHA and the Hierarchy of Controls, if you can remove the hazard or work in fall restraint, those would be “best” or “better” options than fall arrest.

Mobile Fall Protection

A mobile fall protection system is ideal for a two-story building with gutter work, fascia work, or window work because you’re working over the edge of the roof.

Working with HVAC close to roof edges would be another instance where a mobile fall protection system would be a good option for workers to use.

Common Problems for End-Users

Comfort

Our experts see roofing companies and contractors providing safety equipment for the workers, but what happens sometimes is workers feel like it slows them down.

Our fall protection experts often hear that temperatures get hot/humid in the summer months, and workers want to spend less time on hot surfaces and feel their jobs take longer when carrying the added weight of a fall protection system.

Also, not wanting to wear the harness or other fall protection gear could be attributed to the fact that workers have been on the job for years and not fallen.

***Remember, it only takes one fall by even an experienced worker for a catastrophic injury or loss of life to occur, and it could be mitigated with the use of a fall protection system.

Waiting for Something to Happen

According to OSHA, falls lead to the highest number of fatalities in construction, but sometimes, our experts have found roofing companies have been fined multiple times for inadequate fall protection systems. It’s almost as if they’re building those fines into the cost of doing business.

You don’t want to be the company that has something catastrophic happen or be fined heavily for breaking safety regulations when the hazard easily could have been removed or prevented in the first place.

Product Awareness

Our experts and partners have found one of the biggest reasons for workers not wearing harnesses often include a lack of product knowledge or training.

End-users know they need:

- To wear the harness, but don’t know how to wear the harness

- An anchor point, but don’t know how to install an anchor point

- Work fast in hot environments, but harnesses and equipment might slow them down

Proper training starts at the top with management embracing the idea and working in conjunction with their employees to make job sites as safe as possible.

You’re one shortcut away from hurting yourself, your family, and your employer. If you do take a fall off of a roof, and had the opportunity to wear a body harness, but didn’t because you felt it was an inconvenience, that one split-second decision could have lasting results. ***Remember that safety is not just a cost. There are benefits both to end-users and companies to having a safety plan in place. If a fall does take place, companies are facing an expenditure of hundreds of thousands of dollars in medical care, legal situations, and fines.

OSHA Fall Protection Regulations

In accordance with OSHA 1926.503(a), employers must provide fall protection training for all workers who may be exposed to fall hazards. The training must be conducted by a competent person, and include information on how to recognize fall hazards, and on what procedures to follow to minimize them.

Training must address how to inspect, erect/disassemble, and maintain the fall protection equipment involved in the work. Retraining is required when previous training becomes obsolete due to changes in work conditions, fall protection systems, or equipment. Also, retraining is required when worker performance indicates a need for it.

Employers are generally responsible for providing fall protection if workers are exposed to a fall of 6’ or more to a lower level.

Why Training is so Important

According to OSHA Publication 2056, there are nearly 6,000 workplace fatalities in the United States and 50,000 deaths due to workplace-related illnesses each year. Also, there are 5.7 million non-fatal workplace injuries, and those injuries alone cost U.S. businesses over $125 billion annually.

Falls are the leading cause of deaths in the construction industry, and most fatalities happen when employees fall from open-sided floors and through floor openings. Falls from as little as 4’ to 6’ can cause long-term time away from work, or death, which means all open-sided floors and platforms 6’ or more in height must be guarded.

Those who have experience using fall protection equipment typically can don a harness in 30 seconds, and that is time well spent because it could prevent you from experiencing a catastrophic event.

Wrapping it Up

Working at height is serious business, and whether you’re a supervisor, contractor, foreperson, or worker, safety is everybody’s responsibility.

After reading this article, you have a starting point for your roofing fall protection plans, as you learned about:

- Various systems available to your company

- Components, configurations for the systems

- Best fit applications

- Regulations

- Importance of using fall protection systems

It is important to remember that these are only a few of the fall protection systems available for your company to utilize.

At Mazzella FHS, we want the opportunity to help you ensure the safety of your workers by educating you on the fall protection systems available, and how they will benefit your company.

Call us at 800.362.4601 or click here if you need solutions or training for your workers at height!

We are a master distributor for Ultra-Safe, Capital Safety, 3M, Honeywell Miller, Gorbel, Tractel, and Rigid Lifelines … just to name a few. We also build custom fall arrest and fall restraint solutions in-house. We are able to provide the best products for the best price to meet your specific fall protection needs.

Copyright 2021. Mazzella Companies.