Are you in the market for new HMPE (high-modulus polyethylene) Synthetic Rope Slings, but feel somewhat confused after doing some research on different types of lifting and rigging gear?

Because of the time and money you’ll invest in your new slings, Mazzella wants to help you select the correct replacements for your lifting applications. Doing so will allow you and your company to execute safe and efficient lifts with slings in compliance with standards set forth by ASME (the American Society of Mechanical Engineers).

Having been in the rigging business since 1954, Mazzella has the experience you can lean on when ordering new slings. This article is one in a series of many designed to show you how to order the correct slings for your lifting applications.

In this article, you’ll learn the answers to the following questions:

- How many different HMPE synthetic rope sling configurations are there?

- What do you need to know before ordering HMPE synthetic rope slings?

- What types of eyes can HMPE synthetic rope slings have?

- How do you measure the length of an HMPE synthetic rope sling?

- What sling protection is recommended for HMPE synthetic rope slings?

What Factors Do Customers Need To Know Before Ordering HMPE Synthetic Rope Slings?

Many of the same factors that determine your other types of lifting slings apply to HMPE synthetic rope slings.

The main questions you, as an end-user, have to answer include:

- What is the load you will be lifting?

- How much does the load weigh?

- What length of a sling do you need?

- Is there a best sling configuration for your lift?

- Will your slings be exposed to harsh or extreme environmental conditions?

Like other synthetic slings, there’s one major difference for HMPE synthetic rope slings when compared to wire rope or alloy steel chain slings. You have to consider certain aspects of the load to be lifted and the environment in which that sling will be applied, and if they present challenges like:

- Abrasion issues

- Cutting potential

- Melting potential

- Exposure to high-heat environments

What these questions allow our Lifting Specialists to do is figure out all aspects of your lift, or towing application, in order to provide you with the type of sling that best fits your needs. Specifically, there are many types of synthetic ropes that have different strengths, weaknesses, and characteristics. Also, this conversation will help Lifting Specialists figure out if you need abrasion and / or cut protection sleeves.

What Questions Should You Answer Before Ordering HMPE Synthetic Rope Slings?

Our Lifting Specialists welcome the opportunity to come out to your job site(s) to see your application. By answering questions honestly, and combining that with a site visit, it will allow us to provide you the best solution.

Again, being mindful of abrasion, cutting, and melting potential will help Lifting Specialists determine what you need. If you know there are hazards in your lifting applications, asking about sling protection will help you make safer lifts and extend the life of your slings. Knowing what will hold up to your applications and environmental conditions can prevent a catastrophic failure that damages the load, or more importantly, seriously injures / kills workers.

Where Would You Want To Use (and Not Use) HMPE Synthetic Rope Slings?

HMPE synthetic rope slings are good for any environment in which you’re looking to significantly improve your job site safety with lighter and more ergonomic rigging gear.

Years ago, customers started to request HMPE synthetic rope products instead of those made of wire rope or alloy steel chain. This was especially true in the marine, off-shore drilling, and mining industries.

While not the first to use HMPE synthetic rope slings, mining companies wanted to try these products because of the safety aspect. In those early days, HMPE synthetic rope slings were a lot more expensive than they are now. That price decline is a result of increased competition in the supply market.

Originally, there was resistance to the product because it was “soft” or “too light” compared to traditional forms of lifting and rigging gear (wire rope / alloy steel chain). Once customers began seeing the benefits of using these ropes, many of them haven’t gone back to traditional steel rigging gear.

Best-Fit Applications

Oil and Gas Industry

Off-shore operators use HMPE synthetic rope slings to make safer lifts and prevent incidental sparking and fires that could occur with wire rope or alloy steel chain slings.

Coal Mining

Mazzella Lifting Specialists have encountered many companies that run large wire rope winch lines and are trying to replace those because of constant breaks.

Our specialists have found many mining companies are going away from steel just due to safety concerns. Not having the metal components underground is key to preventing several types of workplace injuries.

Mainly, HMPE synthetic rope slings are used to replace chain slings and tow / recovery slings, as well as winch lines on dozers. However, the main hoist ropes must remain wire rope.

Rig Moving

Rig movers in West Virginia and bordering states became interested in HMPE synthetic rope products while using 1.25” or 1.5” wire ropes.

By the time they extended the winch line about 150’, workers were dealing with a cumbersome piece of rigging equipment and broken wires. As they fed the wire rope into the winch, those broken wires exposed workers to severe cuts to their hands.

Also, end-users deal with rust issues, as when a line sits on a winch, it’s exposed to the weather.

Those problems don’t exist with HMPE synthetic rope slings.

Bad-Fit Applications

Although HMPE synthetic rope slings hold up well, especially when you use proper sling protection, there are applications where a wire rope or alloy steel chain product is probably going to work better and be safer.

Most of the time, HMPE synthetic rope slings aren’t the right fit for your job sites because of:

- Melting potential

- Cutting potential

While HMPE synthetic rope slings aren’t easy to cut or melt, once temperatures reach 150°F, the synthetic products start to lose some lifting capacity. You can go up to 140°F, and it’s still at 100% capacity. However, in steel mills, it’s not a good fit because of higher temperatures.

Cutting potential is one of the biggest reasons why companies don’t switch to HMPE synthetic rope slings. Someone who manufacturers steel plates or similar products will need to use another piece of rigging equipment with better resistance to cutting or abrasion. Or you could consider a hybrid sling with the metal components near the cut potential of the load and the HMPE section on top making the sling and below-the-hook load lighter and more manageable.

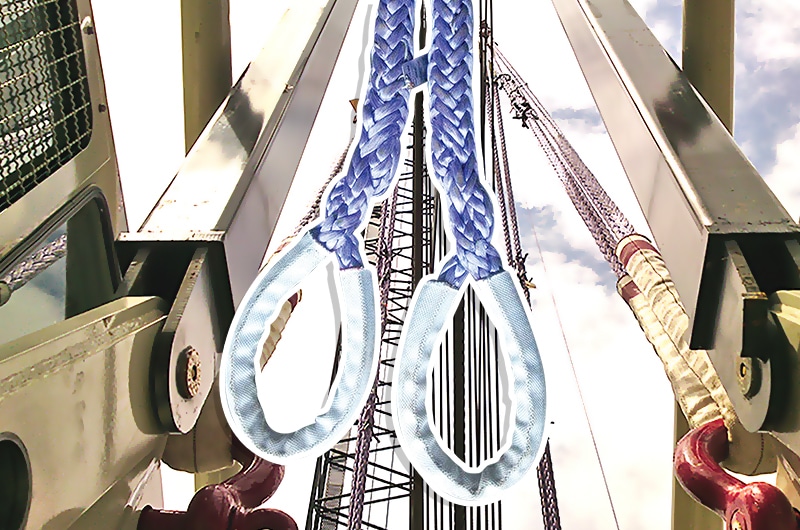

What Are the Different Types of HMPE Synthetic Rope Sling Configurations?

Pretty much any configuration you can have with a wire rope sling or another type of sling, you can have with an HMPE synthetic rope sling.

HMPE synthetic rope slings come in several different configurations, including:

- Single or multi-leg bridle assemblies

- Eyes formed on both ends of the sling

- An endless or infinite loop configuration (similar to a synthetic roundsling)

- With fittings on both ends of the sling

What Types of Eyes Can HMPE Synthetic Rope Slings Have?

Mazzella can make end-users any kind of eye size needed to help you make safe lifts. For example, we have manufactured 3” eyes for specific applications, as well as 3’ eyes for boat face wires.

Also, Mazzella can provide you with synthetic rope slings with soft eyes, thimble eyes, and eyes covered with synthetic cut guards, just to name a few.

Mazzella less commonly manufactures soft eyes with no protection, and instead, puts Cordura®, or another type of protection into the eyes since they will bear the brunt of your lifting applications. Thimble eyes in HMPE synthetic rope slings are rare, but can be used when you need 100% cut protection in the eye.

The drawback is the small cut potential of the metal in the thimble when it comes in contact with unprotected rope. Mazzella goes up a size in the thimble to alleviate the potential contact the synthetic rope would have with the edge of the thimble.

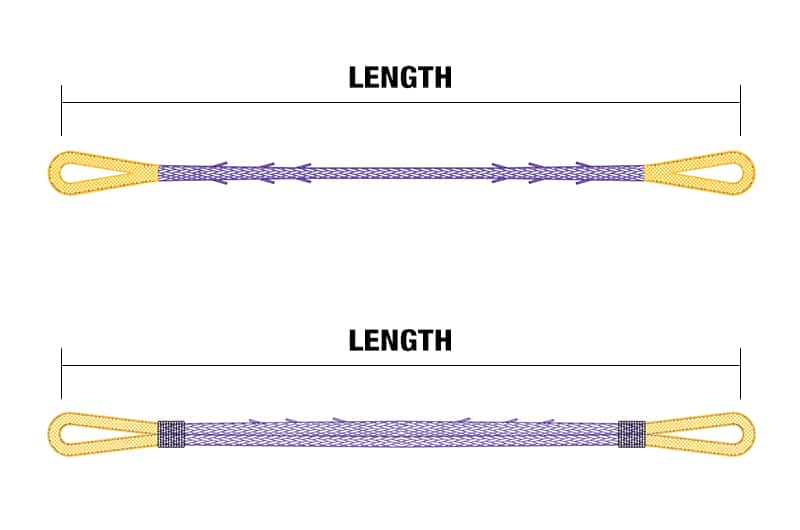

How Do You Measure HMPE Synthetic Rope Slings?

Like other slings, you measure HMPE synthetic rope slings from bearing point to bearing point, which is known as “the reach.”

An eye-and-eye sling length is measured from the top load-bearing point to the bottom load-bearing point. Multi-leg sling assemblies, or single-leg slings with fittings, are measured from the load-bearing point of any rings, hooks, or fittings.

What Sling Protection Is Recommended for HMPE Synthetic Rope Slings?

Mazzella Lifting Specialists recommend many types of sling protection depending on your lifting applications. These include wear pads and tube guards made of:

- Cordura®

- Dyneema

- Spectra

- Kevlar

Tube guards are helpful to keep the eyes and body of the sling safe from damage. Also, you can use magnetic products utilized in wire rope protection to extend the service life of your HMPE synthetic rope slings.

Are HMPE Synthetic Rope Slings the Right Solution For You?

If you want to lift with strong, durable material that doesn’t present similar health hazards to workers as a wire rope or alloy steel chain sling does should it fail, HMPE synthetic rope slings may be the best option for your company.

However, here is what you’ll need to know to order the correct sling for your lifting application:

- Working Load Limit

- Number of legs (single or multi-leg assemblies)

- Configuration

- Length

- Ways to protect slings and loads

If HMPE synthetic rope slings are not a good fit for you, Mazzella offers resources in The Learning Center to help you learn about different types of slings, including:

At Mazzella, we provide ideal lifting solutions—offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We have more than 30 locations across the United States—fully stocked with different sizes and configurations of rigging products for your next project.

Call us at 800.362.4601 or click here to contact a Mazzella Lifting Specialist to learn more about or purchase new slings.

Lifting Slings & Assemblies

Are you looking for lifting slings, including chain, wire rope, synthetic flat web, metal mesh, cordage, and single-path / high-performance roundslings? We can help provide the right sling for your needs!

Additionally, if you need sling assemblies—both large and small, we can manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

Contact us today to get the lifting slings and assemblies you need!

Learn more about lifting slings and assemblies!

Copyright 2022. Mazzella Companies.