Why Did HMPE 12 Strand Ropes Become Popular in the Rigging Industry?

How did HMPE 12 Strand ropes become popular in the rigging industry? By providing safer lifts without sacrificing lifting capacity, HMPE 12 Strand ropes have become the preferred piece of rigging equipment for many industries, including mining, oil and gas, and rig moving.

Are you looking for new slings to address issues of durability, weight of your current rigging equipment, or difficulty to maneuver wire rope or alloy steel chain, and hearing that HMPE 12 Strand ropes are a viable alternative to traditional rigging gear?

Synthetic ropes sound like a good product, and they have gained popularity within the rigging industry. However, you’re not sure and still have questions about it being the right fit for your company.

For more than a decade, Mazzella has provided these synthetic ropes to customers across the country. We’re here to help educate you on the benefits of using HMPE 12 Strand Ropes, and if they will help fill your needs.

In this article, you’ll learn about HMPE 12 Strand ropes and their:

- History

- Best fit applications

- Usage in mines

- Comparability to traditional lifting slings

- Bad fit applications

- Benefits to using HMPE 12 Strand ropes

- Lifecycle and how to extend it

When Did HMPE 12 Strand Ropes Become More Widely Used?

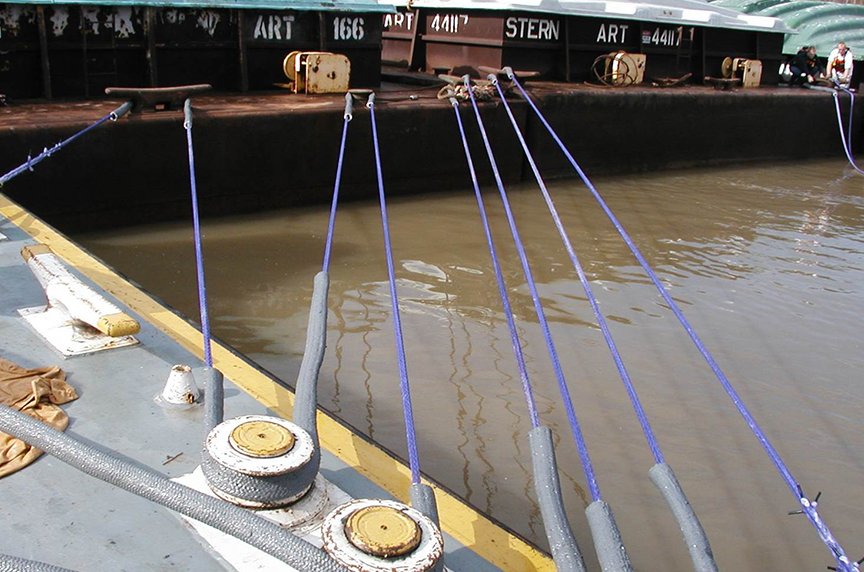

Many years ago, customers started requesting synthetic ropes instead of those made of wire rope or alloy steel chain. This was especially true in the marine, off-shore drilling and mining industries.

While not the first to use HMPE 12 Strand ropes, mining companies wanted to try these products because of the safety aspect. In those early days, HMPE 12 Strand ropes were a lot more expensive than they are now. That price decline is a result of increased competition in the supply market once the demand increased.

Originally, there was resistance to the product because it was “soft” or “too light” compared to traditional forms of lifting and rigging gear (wire rope/alloy steel chain). Once customers began seeing the benefits of using HMPE 12 Strand ropes, many of them haven’t gone back to traditional rigging gear.

Now, manufacturers are producing more advanced HMPE 12 Strand ropes to meet the demands of the market.

Cortland, an industry-leading synthetic ropes provider, has a product called GTM, which is a composite double braid rope. GTM is similar to a 12-strand HMPE (High Modulus Polyethylene) rope, but it’s got a Dyneema cover over it and a reinforced Plasma® core.

You could take a 5’ piece and hold it out, and it won’t sag despite being a synthetic product. Manufacturers figured out if synthetic products are going to be used in winch lines, they should make a rope specifically for use on a winch line.

It’s one thing to give it a try and say, “you heard about HMPE 12 Strand ropes and you want to give it a try.” It’s another thing to get that repeat customer that comes back and says, “Oh, I tried out one line, and want to replace more of my current lines with synthetics.”

Converting End-Users to HMPE 12 Strand Ropes

HMPE 12 Strand ropes began their rise in popularity because:

- They are a much safer product than other lifting gear due to:

- Weight-to-strength ratio

- Safer breaks

- In many applications, it’s a much better fit

By converting some mining companies to synthetic ropes, distributors have helped many more workers go home safely at the end of their shifts instead of suffering serious injuries or death when a wire rope or alloy steel chain broke while in use underground.

At first, some companies rejected synthetic products, and instead, laughed at the idea that they’d be as effective as wire rope or alloy steel chain. Some customers asked, “I’m trusting my life to this thing?” However, after customers gave it a chance, the laughing stopped and the popularity increased.

Manufacturers have pushed development and expanded what their products are able to do, including the potential to convert crane ropes to synthetic ropes.

Best-Fit Applications for HMPE 12 Strand Ropes

Oil and Gas Industry

Off-shore operators use HMPE 12 Strand ropes a lot to make safer lifts and prevent incidental sparking and fires that could occur with wire rope or alloy steel chain products.

Coal Mining

Mazzella Lifting Specialists have encountered many companies that run large wire rope winch lines and are trying to replace those because of constant breaks.

Those specialists have found many mining companies are going away from steel just due to safety concerns. Not having the metal components underground is key to preventing several types of workplace injuries.

Mainly, these synthetic ropes are used to replace chain slings and tow/recovery slings, as well as winch lines on dozers. The main hoist ropes must remain wire rope.

Rig Moving

Rig movers in Southern West Virginia became interested in HMPE 12 Strand ropes while using 1.125” or 1.5” wire ropes.

By the time they extended the winch line to 150’, workers were dealing with a cumbersome piece of equipment. Also, they were working with broken wires. As they’re trying to feed the wire rope into the winch, those broken wires exposed workers to severe cuts to their hands.

Also, end-users have to deal with rust issues, as when a line sits on a winch, it’s exposed to the weather.

Those problems don’t exist with these synthetic ropes.

How Are HMPE 12 Strand Ropes Used in Mines?

In three words: Pretty much everything.

These ropes are used in lifting and winching applications underground.

The HMPE 12 Strand ropes are used mostly for towing and recovery. That’s important because in several types of mines, workers sometimes deal with knee-high waters. Equipment gets hung up or breaks down constantly because you can’t really repair it easily once it’s under water.

There are surface mines that have large rock trucks that will be completely loaded down with coal or rock that workers are trying to move out of the way. Usually, that involves moving the rock trucks up a significant grade.

Chains will break down over time and get stuck, which creates a more hazardous working environment. If the chains break, that could release a loaded rock truck down a steep hill and send it careening toward unprotected workers, as well as the danger of the projectiles from the broken chain under tension and what that poses for those in close proximity.

With 2” or 3” diameter HMPE 12 Strand Ropes, miners will pull those trucks out of the mines safely.

Mazzella Lifting Specialists worked with a mining company that wanted to test synthetic ropes against more traditional lifting slings. This company had a Caterpillar D11 Dozer stuck in the ground. They were simulating a worst-case scenario breakdown.

They took a 5/8” diameter Grade 100 alloy steel chain sling, tied it to the Dozer and tried to pull the Dozer out of the mud. The chain broke, and they found one of the links 75 yards away. If someone was standing 10 yards away when that break happened, that person would have experienced serious injury or death.

Then, they used synthetic ropes, and pulled the Dozer out of the mud without issue.

Can HMPE 12 Strand Ropes Really Match Traditional Lifting Steel Slings?

The HMPE 12 Strand ropes and HMPE Dyneema ropes are considered a replacement for wire rope and alloy steel chain within the construction and manufacturing industries.

But how do you match the lifting capacity of traditional rigging gear?

Say you have a 1” wire rope sling and 20’ eyes on each end with two legs. You’re wondering, “What do I need in terms of HMPE 12 Strand ropes to equal the lifting power of my existing wire ropes?”

Whatever you’re using the wire ropes line for, these synthetic ropes are manufactured to meet those same specifications. The HMPE 12 Strand ropes have a little bit higher break strength than a general purpose wire rope of the same diameter.

Example: Concrete Bridge Removal

One customer specializing in concrete removal and bridge deconstruction made the switch to HMPE 12 Strand ropes. To meet the demands of the job, the synthetic ropes where covered with sling protection. The customer actually wrapped these synthetic slings around rugged pieces of concrete and moved them to make a way for a new construction project.

Sling protection is a really nice feature. You can protect the synthetic slings with different types of guards based on your needs. These are enhancements that make HMPE 12 Strand ropes slings even more durable.

Are There Applications Where HMPE 12 Strand Ropes Might Not Be a Good Fit?

Although HMPE 12 Strand ropes hold up well, especially when you use proper sling protection, there’s some applications where a wire rope or alloy steel chain product is probably going to work better and be safer.

Most of the time, synthetic ropes aren’t the right fit because of:

- Heat

- Cutting potential

While synthetic ropes aren’t easy to cut or melt, once temperatures reach 150°, the synthetic products start to lose lifting capacity. You can go up to 140°, and it’s still at 100% capacity. However, in steel mills, it’s not a good fit because of high temperatures.

Cutting potential is one of the biggest reasons why companies don’t switch to HMPE 12 Strand ropes. Someone manufacturing steel plates or similar products will need to use another piece of rigging equipment with better resistance to cutting or abrasion.

Synthetic ropes are more expensive than other, more traditional types of rigging gear.

What Are the Benefits to Using HMPE 12 Strand Ropes?

Safety is the “crown jewel” of any lifting activity, but it’s not the only benefit to using HMPE 12 Strand ropes.

Lower Injury Risk

Like the Green Pin Tycan® Chain, HMPE 12 Strand ropes are much lighter than equivalent wire rope or alloy steel chain products.

They weigh about 1/8 that of wire rope or alloy steel chain slings. Because of this, your workers will experience fewer injuries and days off work.

Also, fewer injuries have increased morale among workers.

During on-site visits to offer HMPE 12 Strand ropes, Mazzella Lifting Specialists initially heard from managers that “Our employees won’t take care of it, so paying more just doesn’t make sense. They’re just going to trash it. They’re not going to care for it.”

However, what those detractors have found is if they do give HMPE 12 Strand ropes a chance, employees actually prefer working with it. They’re taking care of the product and making sure it isn’t going anywhere.

Decreased Setup Time

In certain situations, rigging equipment is too heavy to move without assistance from machinery. A 1.5” four-legged chain sling with 20’ legs will need to be moved to the crane by another machine.

With HMPE 12 Strand ropes, it only takes one person to move the lifting equipment around a jobsite.

Safer Breaks

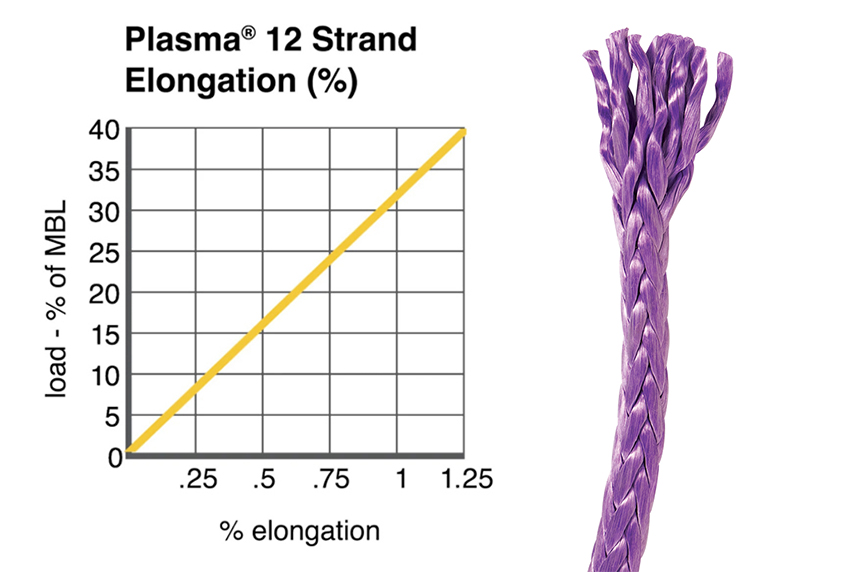

HMPE 12 Strand ropes have a much safer break than wire rope or alloy steel chain products due to kinetic energy.

When HMPE 12 Strand ropes break, no matter really how much tension is on the product, what diameter you’re using, or how much weight is being lifted, it’s just going to fall to the ground instead of whipping and lashing.

Also, there are no projectiles, which is one of the leading hazards when using an alloy steel chain sling.

Resistance Against Breakdown

Cortland did research with different acids and bleaches, corrosive materials that could damage the slings. After soaking in these materials for six months or a year, Cortland conducted break tests with the synthetic products. They broke at nearly 100% capacity.

Also, ultraviolet (UV) light does not affect the working load limit of HMPE 12 Strand ropes. Nylon slings and flat web slings will be affected by UV light and need to be removed from service after prolonged exposure. While the HMPE 12 Strand rope’s color might lighten, UV light doesn’t affect the working load limit.

Environmental conditions don’t affect HMPE 12 Strand ropes like other lifting and rigging equipment. If you go on a jobsite and there’s a layer of ice on your winch line, you can literally knock off the ice. After making sure the line is free from obstruction, you can get to work.

HMPE 12 Strand ropes float, and there’s no grease or oil usage that could contaminate nearby water supplies. It’s a greener product, and slightly stronger than general purpose wire rope.

No “Memory”

There’s no core in HMPE 12 Strand ropes, so there’s “no memory” from previous lifts.

Also, HMPE 12 Strand ropes will winch much easier. There’s no fight in it. There’s no wrestling with it to get it to fall into place. It’ll fall where it’s supposed to be.

Additionally, there’s no dog legs, which is common in wire rope slings after they’re used in a basket or choker hitch formation. Think of the dog-legged wire rope slings as a paperclip. When you try to pull it in a straight line again, those wires are going to snap.

How Do Companies Maximize the Lifecycle of their HMPE 12 Strand Ropes?

Although HMPE 12 Strand ropes have cut potential, there are ways to protect the product so it reaches its full lifecycle.

Lifting specialists recommended you use sling protection when lifting with these synthetic ropes. Cut guards are light, and easier on loads than direct contact with wire ropes or alloy steel chains. It doesn’t damage your loads like wire rope or alloy steel chain could.

Additionally, proper training of your employees will help maximize the lifecycle for your HMPE 12 Strand ropes.

In applications with a lot of dust and rocks, one option is to cover the whole HMPE 12 Strand rope with protection. There are chafe guards made of a thin material that add very little weight and cost to the HMPE 12 Strand ropes. Covering your entire sling can help tremendously with internal abrasion.

Sling protection adds significant life to the HMPE 12 Strand ropes, especially in harsh environments. Even if it’s not the most expensive guard, your investment will keep damaging material from harming your lifting slings.

If you’re looking to maximize protection, manufacturers produce cut guards made out of Dyneema synthetic fibers. They’ll help keep the HMPE 12 Strand ropes from experiencing cuts in rigorous applications.

Are HMPE 12 Strand Ropes a Fit for Me?

HMPE 12 Strand ropes may sound like a good idea for you, but they’re not a fit for everybody’s company.

Alloy steel chains are durable pieces of rigging equipment, and have their best-fit applications, despite their high tension increasing the potential for catastrophic incidents. The same is true for wire rope. While wire rope has its best-fit uses, broken strands could recoil and severely injure workers in its path.

It’s important to do your research on synthetic ropes, and also, understand the types of materials you lift regularly. Those two steps will go a long way in deciding what is the best type of rigging equipment for you.

Mazzella is a distributor of all major synthetic rope and sling products including, but not limited to:

- Plasma®

- Twin-Path®

- Green Pin Tycan®

- Samson

- New England Ropes

- Yale

Call us at 800.362.4601 or click here to contact a lifting specialist to learn more about or purchase HMPE 12 Strand ropes.

Slings & Assemblies

Mazzella’s quality slings include chain, wire rope, metal mesh, synthetic flat web, polyester roundslings, cordage, and high-performance roundslings.

We can also manufacture assemblies with standard or custom end fittings.

Copyright 2021. Mazzella Companies.