A How-To Guide for Ordering Synthetic Roundslings

Did a recent inspection reveal your current synthetic roundslings are no longer in compliance with the standards set forth by ASME B30.9 Slings? Are you confident that ordering new synthetic roundslings will allow you to continue your lifting applications safely and efficiently?

Although you know new synthetic roundslings are needed, there may be some confusion with how to order the right replacement slings so you and your company can continue lifting safely, and with minimal downtime.

Having been in the rigging business since 1954, Mazzella has the experience to help clear up that confusion. This article is one in a series of content designed to show you how to order the correct slings for your lifting applications.

In this article, you’ll learn the answers to the following questions:

- What do you need to know before ordering synthetic roundslings?

- What questions should you be prepared to answer before ordering a synthetic roundsling?

- What questions should you ask before ordering a synthetic roundsling?

- Where would you want to and not use synthetic roundslings?

- What types of eyes can synthetic roundslings have?

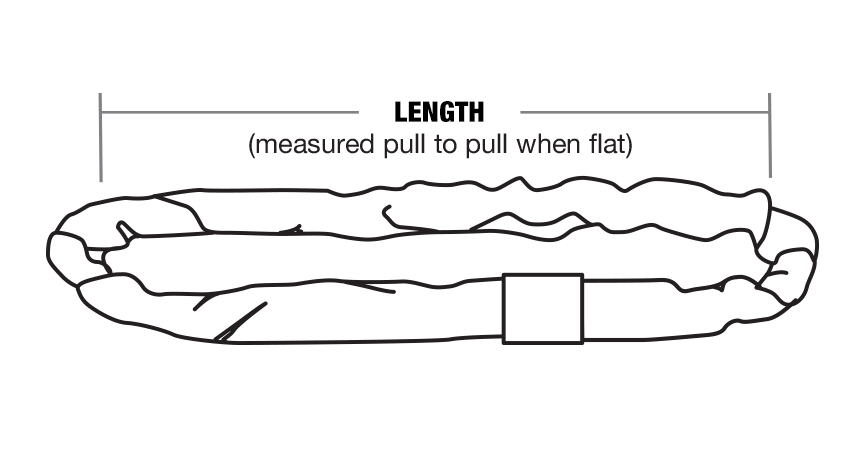

- How do you measure synthetic roundsling length?

- What protection is recommended for synthetic roundslings?

What Are the Types of Synthetic Roundsling Configurations?

If you’re using a roundsling in a basket hitch and use a sleeve, the body of the sling will be protected from incurring damage from the crane hook. This could create an eye-and-eye roundsling to use with hooks and other hardware.

Also, you can attach roundslings to master links and have multiple-leg bridles. There are hooks made specifically for use with roundslings. The hook has a triangular or flat eye, which allows the roundsling to rest easily within that eye and avoid being pinched or bunched while under load.

Because a roundsling is designed in an endless configuration, the only time it would actually have an eye is if you put a protective jacket around it.

What Do You Need to Know When Ordering a Roundsling?

First and foremost, you need to know the capacity and length of a roundsling for you to execute successful lifts. Because roundslings are made from polyester, they are susceptible to abrasion and cutting when exposed to edges and rough surfaces.

Roundslings are very versatile, and can be used in a vertical, choker, or basket hitch. When you’re using them in a basket hitch, be sure you get a nice surface area connection with the roundsling and the load.

Depending on a roundsling’s size, they can be cost-effective as well.

While they’ll be more expensive than web slings, there are additional benefits. If the roundsling’s jacket is damaged, but the internal fibers remain intact, the jacket can be repaired. If you get a snag in the jacket, and it creates a hole, you can send it in for inspection. If the core yarns aren’t damaged, we can actually put a patch on that sling, proof test it, and if it passes, we’ll send the roundsling back to you for use in the field.

What Questions Should You Be Prepared To Answer Before Ordering a Roundsling?

A lifting specialist needs to know the length and capacity of slings you’ll need to execute your lifts successfully.

With roundslings, the length is going to be measured under tension. There have been times when customers will cut an out-of-service roundsling to measure its length. They’ve said, “I need a 20’ sling.” What they likely need is a 10’ roundsling.

What Are Good and Bad-Fit Uses For Roundslings?

Good-Fit Applications

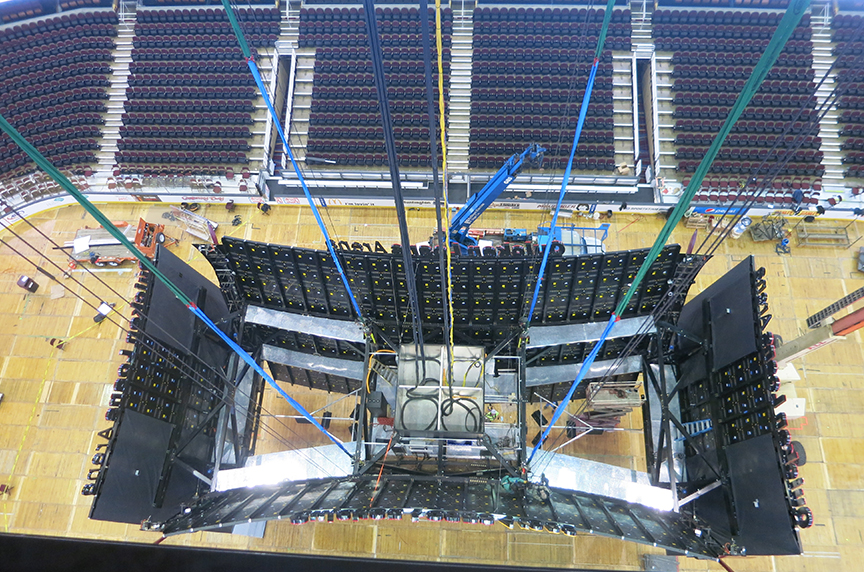

Despite their challenges, polyester roundslings are gaining in popularity in the construction industry. They are easy to handle, as well as transport to and from multiple job sites. Because of their material and construction, synthetic roundslings won’t add much more weight to what you’re already picking up.

Also, roundslings are good to use in most manufacturing environments, so long as they’re not exposed to pinch points or sharp edges.

Bad-Fit Applications

Hot environments are not ideal for synthetic roundslings. The fibers and the jacket will begin to melt at elevated temperatures, and that will cause a potential safety hazard.

While the woven outer jacket has no load-bearing capability, it is designed to protect the internal load-bearing fibers and core yarns against abrasion, dirt, grease, and UV degradation. Polyester roundslings are suitable for acidic environments, or near chemicals used as bleaching agents, but should not be used in alkaline environments.

Like web slings, roundslings are more susceptible to heat damage and should not be used in environments that exceed 194°F or below -40°F. For loads with sharp edges, corner protectors or edge guards should be used to protect the sling from cuts and tears.

If used outdoors, they should be stored in a cool, dark, and dry environment to avoid prolonged exposure to sunlight and UV rays, which can damage and weaken the strength of the sling. When a lift is made at the working load limit (WLL), the user can expect approximately 3-5% stretch when using a roundsling.

How Can You Protect Your Synthetic Roundslings?

Roundslings are a continuous loop, measured from bearing point to bearing point. You can put a sleeve (pad) over the sling. These sleeves can be sewn to the jacket, and use Velcro to connect the sleeve to the bearing point to protect it from abrasion.

Also, you can put a protective sleeve over the body of roundsling. Then, you end up with a roundsling that has eyes on each end. From there, you can use the roundsling like an eye-and-eye flat web sling, and it will be more protected if you’re going around hard or sharp edges.

Cordura® jackets are the most popular form of protection on a roundsling. While Cordura® already is in the jacket of the roundsling, an additional sleeve will add more material that can be sewn on permanently.

The most cost-effective protection is Cordura®. Our rigging shops are designed to produce and distribute these protection sleeves to you without much lead time.

Are Roundslings the Answer For You?

If you want to switch from heavy wire rope or alloy steel chain slings to a synthetic roundsling, or you’re replacing a sling that’s been damaged or failed inspection, here’s what you’ll need to know to order the correct style sling for your lifting application:

- Working Load Limit

- Number of legs (single or multi-leg assemblies)

- Sling configuration (eye style or fitting style on each end)

- Sling length

- Additional cut, wear, or abrasion resistance

However, if after reviewing this piece, you believe roundslings are no longer a good fit for your lifting needs, Mazzella offers resources in The Learning Center to help you learn about different types of slings, including:

- Flat web slings

- Wire rope slings

- Slingmax® Twin-Path® slings

At Mazzella, we provide ideal lifting solutions — offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We have more than 30 locations across the United States — fully stocked with different sizes and configurations of rigging products for your next project.

Call us at 800.362.4601 or click here to contact a lifting specialist to learn more about or purchase new slings.

Lifting Slings & Assemblies

If you are interested in chain, wire rope, metal mesh, synthetic flat web, polyester roundslings, cordage, and high-performance roundslings, we can help provide the right sling for your needs.

If you need sling assemblies—both large and small, we can manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

Contact us today to get the lifting slings and assemblies you need!

Learn more about lifting slings and assemblies!

Copyright 2021. Mazzella Companies.