A How-To Guide for Ordering Wire Rope Slings

Are you in the market for new wire rope slings, but feeling somewhat confused after doing some research on different types of lifting and rigging gear?

Because of the time and money you’ll invest in ordering new slings, Mazzella Companies wants to help you select the correct replacements for your lifting applications. Doing so will allow you and your company to execute safe and efficient lifts with slings in compliance with ASME (American Society of Mechanical Engineers) standards.

Having been in the rigging business since 1954, Mazzella Companies has the experience you can lean on when ordering new slings. This article is one in a series of content designed to show you how to order the correct slings for your lifting applications.

In this article, you’ll learn the answers to the following questions:

- What are the different types of wire rope sling configurations?

- Mazzella 7-Part™

- Single-Part

- What do you need to know before ordering wire rope slings?

- What questions do you need to answer before ordering a wire rope sling?

- What questions should you ask before ordering a wire rope sling?

- What types of eyes can wire rope slings have?

- What eyes are best for which applications? Why would you choose one over the other?

- How do you measure wire rope sling length?

- What sling protection is recommended for wire rope slings?

- Where would you want to and not use wire rope slings?

What Are the Types of Wire Rope Sling Configurations?

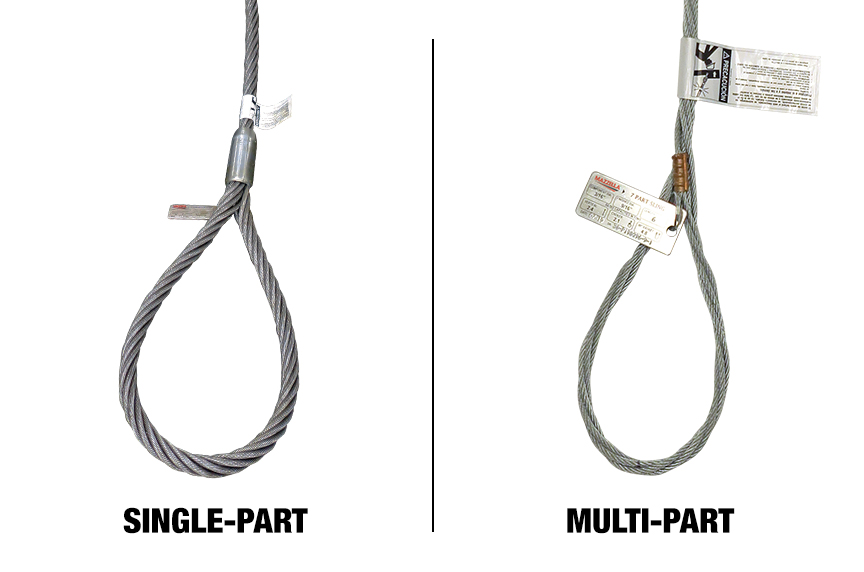

Single-part slings are your traditional / standard wire rope slings. It’s got a mechanical splice, and that one piece of wire rope can be customized to the size you need. When manufactured, the strands will be split, and the flemish eye will be created.

Company founder Jim Mazzella created the Mazzella 7-Part™ wire rope slings. These slings are made with one continuous piece of rope. When a 16’ Mazzella 7-Part™ sling is manufactured, it will take close to 200’ of rope to complete. The manufacturer will cut 200’ of wire rope, and will walk it back and forth seven times before braiding it into an eye.

When the component rope is braided, it creates a larger diameter in the body of the sling. The sling looks like one continuous piece of rope, but strands can be separated. That’s what gives the Mazzella 7-Part™ sling its flexibility.

We can make Mazzella 7-Part™ slings to any length or size you need. We can thimblize the eyes and change the size of the eyes.

Most wire rope slings are single-leg configurations, but multi-leg sling assemblies, often called bridles, can be ordered in double, triple, or quad leg configurations.

Multi-Leg Wire Rope Slings

The advantages of a multi-leg wire rope sling include:

- Greater flexibility

- Fatigue resistance

- Ergonomically rig up loads easier

Multi-leg slings can come with two, three, or four legs of wire rope connected by and hanging from a master link when lifting a load.

When determining wire rope bridle, you want to choose the correct master link, or pear link, along with the proper size, so it can fit over your crane hook. Also, at the bottom of the wire rope bridle, you want to determine the proper components you’ll need to make safe, successful lifts.

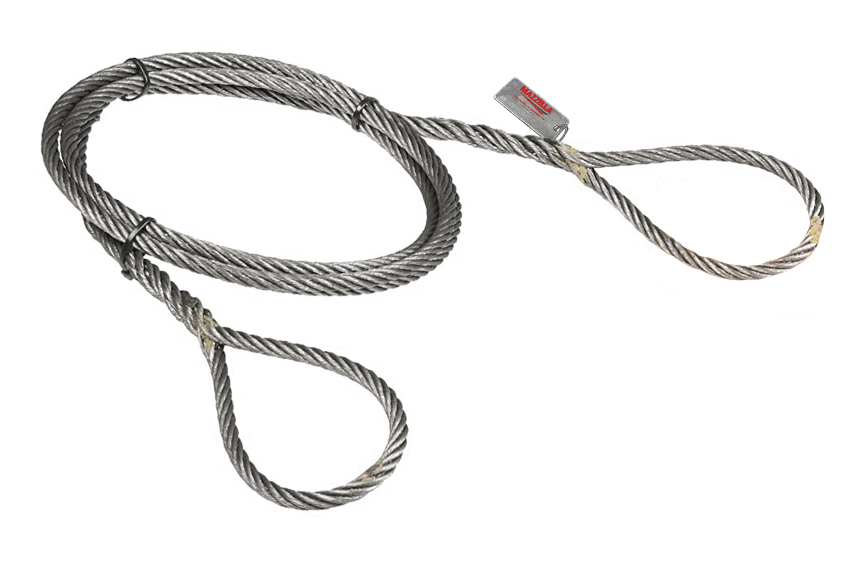

Endless Wire Rope Slings

Also known as grommets, you’d want to use these types of slings when lifting a capacity above the capabilities of an eye-and-eye sling. Endless slings can be used in applications where headroom is an issue because they can be manufactured smaller than an eye-and-eye sling.

What Do You Need To Know Before Ordering a Wire Rope Sling?

There are several factors to take into consideration when ordering wire rope slings, including:

- Capacity needs

- Sling length

- Any special eye configurations

- Hitch type

- Single-leg (straight vertical)

- Eye-to-Eye (choker hitch where one eye goes through the other)

- Basket hitch (goes underneath load and both eyes go vertical)

Example: Say you call Mazzella and tell our specialists, “I don’t know what I need. I just know I need a wire rope sling for this capacity, and I’m using this type of hitch to execute my lift.”

Our experts will then check the finished sling diameter needed to make your lifts safely. The strength of the rope is really determined by the diameter of the rope. If you’re lifting loads of 2,000 lbs., we’re likely to recommend using a 3/8” diameter rope. As you go up in diameter, the eyes get larger.

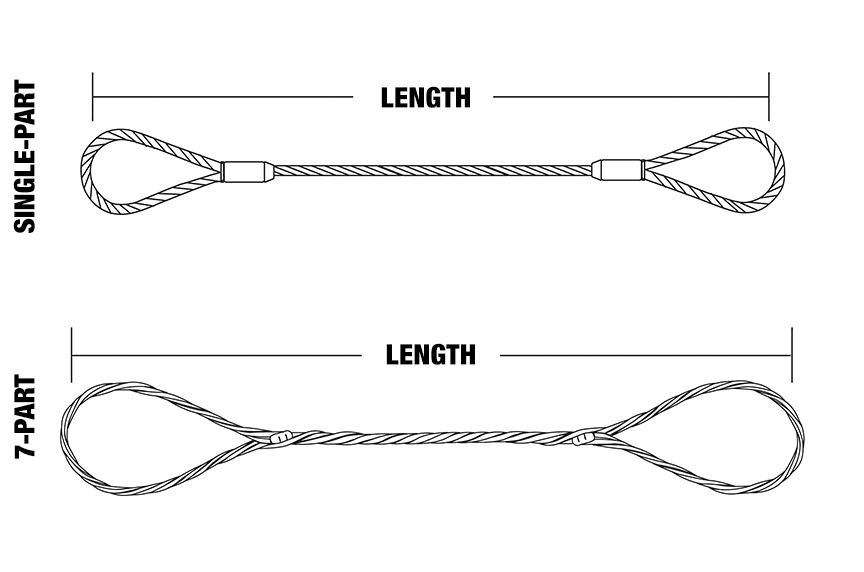

Sling length is measured from the bearing point of one eye to the bearing of the other eye. To measure your slings accurately, lay it on the ground and measure from bearing point to bearing point.

The D/d ratio is another factor to consider when ordering wire rope slings. D/d ratio is the ratio of the diameter of the load being lifted divided by the body diameter of the sling.

For the diameter of the sling, the working load limit is based on your D/d ratio. To maximize the work life of your wire rope sling, you want to use a 1” diameter pin or possibly larger, but not so large that you stretch the eye. You want the D/d ratio to be close to one-to-one.

What Questions Do You Need To Answer Before Ordering a Wire Rope Sling?

“What are you picking up?”

That is one of the first questions our lifting specialists ask, not so much that it matters what you’re picking up, but it’s more so to understand your needs. It helps us understand the shape of the items being lifted, and what additional needs you may have.

The next few questions are:

- How heavy are the items being lifted?

- How many slings are you going to use to pick up this item?

- How many pick points do you have?

Example: If you have four pick points, and will use four slings, you can calculate how to distribute the load across the slings needed for the lift. If you’re lifting a load with a spreader beam, you have to calculate sling angles to accurately figure your capacity.

If your entire load weighs 20,000 lbs., you don’t need slings rated for 20,000 lbs. However, you could buy slings rated for 20,000 lbs., especially if it’s a safety issue. If someone on the safety team says, “We just need and want all the slings rated for the entire load,” we can fulfill that request. Those slings will be larger than normal, and also, more expensive.

What Other Factors Should Be Considered When Ordering Wire Rope Slings?

For ordering a wire rope sling, a customer should inform the lifting specialist of any corners or sharp edges the sling might encounter during a lift. This will allow for the specialist to figure out what type of protection is needed to eliminate that edge on the sling.

Remember, just because the wire rope sling is made out of steel, it doesn’t mean it can’t be damaged by an edge or corner. Once you put a load on the sling, a sharp edge could cut, crush, or damage the wire.

If the load you’re lifting is at or near capacity, any hard edges could damage your wire rope sling, or lead to catastrophic failure. Once multiple wires become broken or cut, the sling is compromised and needs to be removed from service and replaced by one in compliance to ASME standards.

The more abrasion a wire rope sling encounters, the more those wires will wear down and wear out. A small financial investment of a sleeve really will prolong the life of the wire rope sling.

What Type of Protection Is Recommended for a Wire Rope Sling?

For wire rope slings, a sleeve is a common type of protection. It’s a tubular sleeve with a thin layer of padding, and that allows the sling to go around those edges and softens the contact between the sling and the load.

While protecting the sling is key, it’s not so much on the body, but rather, in the eye of the sling that matters. If you’re going to have a hook in the eye, you want a thimble in there because it’s going to help with the D/d ratio. When you’re putting tension on the sling, the thimble will collapse a little bit. If you don’t have that protection in the eye of the sling, the hook could damage/ruin your sling.

Having the thimble in the eye is what really helps protect against abrasion from the hook sliding around as tension is put on the sling during a lift. Anytime you have a connection, even if you’re just putting a shackle through the eye, using thimbles could help protect your slings.

There are many types of thimbles available, including

- Crescent thimbles

- Slip-on thimbles

- Slip-through thimbles-These thimbles have tabs that go around the rope in the eye, but you retain a standard eye size.

Also, for the sling itself, you can utilize a swatch sleeve. Before a manufacturer finishes the second eye of the sling, they’ll slide a clear tubing over the body of the sling. This added protection helps keep debris out of the valleys of the rope. It’s a simple clear rubber tubing that will help prolong the life of the sling.

Protecting the Sling and the Load

Using sling protection not only helps prolong the life of your rigging gear, but also, the items you’re picking. If you have anything that you don’t want to get damaged, you want to use sling protection. It could just be as simple as using a pad in-between the load and your sling that’ll help protect both from any kind of damage.

Where Would You Use and Not Want to Use a Wire Rope Sling?

Good-Fit Applications

Wire rope slings are a durable piece of rigging equipment that are good fits for the following environments:

- Field use in the elements

- Steel mills

- Rough-terrain situations

Bad-Fit Applications

While there are plenty of environments where wire rope slings would be a good fit, there are other situations where they’re not ideal.

If you’re concerned about protecting your loads during lifts, web slings would be a better fit. They’re not as abrasive on your materials. Also, the weight of a wire rope sling is something to take into consideration when calculating the capacity of the lift.

In your lift plan, you need to account for the weight of your rigging gear. If you’re approaching the capacity of your crane, and you start adding up the rigging, larger diameter wire ropes are going to be heavier. This may put you over capacity.

What Types of Eyes Are Available for Wire Rope Slings?

If you have to put the wire rope sling eye over a hook or through a shackle, you want that eye to be the appropriate size and fit.

In determining eye construction, there are multiple types:

- Flemish eye

- Hand-tucked eye

- Thimble eyes

Flemish Eye

With a flemish eye, the wire rope is split apart, and then, crossed to a point that is marked at the top of the eye. Then, manufacturers will start weaving the rope back into itself. The wire rope falls into the grooves, and then, a swedge sleeve will be hammered down. Then, the sleeve is put into a swedger, and will be compressed to finish off the eye. After a good swedging, the wire rope looks like a piece of solid steel.

Mazzella does the flemish eyes in its wire rope slings because the efficiency rating is much higher. Typically, a flemish-eyed sling has efficiency ratings in the high 90%, and that means you’re getting the strongest, highest quality eye available.

Hand-tucked Eye

In this configuration, the individual strands are broken up and woven into the body of the sling to create that eye.

Our specialists have found over time that steel erectors have preferred to use the hand-tucked eyes because of their ease of use. They slide under beams much easier than flemish-eyed slings. Also, they don’t get caught like the knuckle of the swedge sleeve could.

Thimble Eyes in Wire Rope Slings

Regardless of size, the thimble can be added to reinforce and help keep the integrity and construction of the eye.

Are Wire Rope Slings the Answer For You?

Wire rope slings are versatile and common pieces of rigging equipment.

Learning more about the different parts and terms associated with this product will allow you to determine if it will meet the needs of your company and help you conduct safer overhead lifts.

However, if after reviewing this piece, you believe wire rope slings are no longer a good fit for your lifting needs, Mazzella offers resources in The Learning Center to help you learn about different types of slings, including:

- Roundslings

- Web slings

- Slingmax® Twin-Path® slings

At Mazzella, we provide ideal lifting solutions—offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We have more than 30 locations across the United States—fully stocked with different sizes and configurations of rigging products for your next project.

Call us at 800.362.4601 or click here to contact a lifting specialist to learn more about or purchase new slings.

Copyright 2021. Mazzella Companies.