3-5 | Best Practices for Maintaining Alloy Chain Slings

<p>The best way to help extend the life of a chain sling, and help to ensure that it stays in service, is to properly maintain it during and in-between each use. Inspections are easier to perform—and probably more thorough—when slings are easily accessible and organized, kept off of the ground, and stored in a cool and dry environment.</p>

Often times, chain sling abuse is inherent with a given application. However, by knowing what types of applications cause premature chain wear and even sling failure, the rigger can be in a better position to know what to look for when inspecting slings.

The best way to help extend the life of a chain sling, and help to ensure that it stays in service, is to properly maintain it during and in-between each use. Inspections are easier to perform—and probably more thorough—when slings are easily accessible and organized, kept off of the ground, and stored in a cool and dry environment.

Hang your slings or keep them in a designated locker or rigging box where they are off of the ground and will not be subjected to mechanical damage, corrosive action, moisture, extreme temperatures, and kinking.

Overload / Sling Angle

Overload normally causes chain stretch. The overload can be the result of the load itself weighing more than the sling’s capacity.

Severe angles can also result in a sling being overloaded. Alloy chain sling charts have rated capacities at 30°, 45°, and 60° angles. The typical angle is 60°. Normally two, three, and four leg chains have three ratings for a specified number of pounds at 60°. The sling identification tag also states the rated capacity for the specified sling angle. Be aware that sling angles greatly affect the tension on each leg of the sling. The farther apart the legs of the sling are spread, the more tension there is on the sling legs.

A good rule of thumb is to measure the distance between the hook-up points, and have the sling legs measure at least that long. For example, if the distance between the hook-up points measures 10 feet, then the sling legs should be at least 10 feet long. This practice ensures that the two leg lengths and the distance between the hook-up points form an equilateral triangle resulting in the sling angles being 60°.

If the application dictates sling angles less than 60°…

then the user needs to choose the correct size sling to allow for the more severe angle. In any case, never use a sling at angles less than 30°. This concept for sling angles and leg lengths applies to all sling types—not just chain slings.

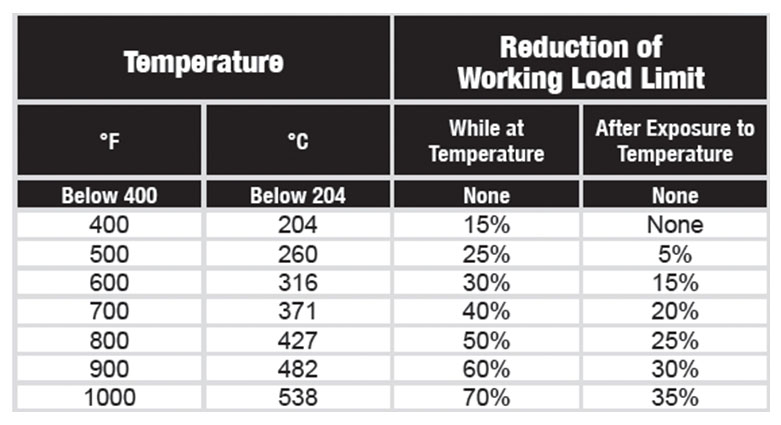

Temperature

In applications involving high heat, the user must pay attention to the amount of direct heat that the chain sees. Often, direct heat results in the chain turning a blueish color. The user should consult the chain manufacturer’s capacity reduction charts relating to heat. In addition, be aware of any damage caused by weld splatter or molten metal being splashed on the slings.

Edge and Cut Protection

Slings in contact with edges, corners, or protrusions should be protected with a material of sufficient strength, thickness, and construction to prevent damage to the sling. Edge protection and cut protection should be used on all edges and corners—even the ones that aren’t load-bearing surfaces.

Keep Your Slings Clean

Continual exposure to dust, dirt, and moisture can degrade the materials over time and shorten the life expectancy of the product. Keep your slings clean and stored in an area free of moisture to avoid excess corrosion and pitting of the links, fittings, and hardware.