Below-the-Hook Lifting Devices

<p>What do you do if you feel like your crane isn’t performing as efficiently or as safely as you think it can? Maybe it takes too long to secure or remove each load using traditional rigging slings and hardware. Or, maybe something just doesn’t seem right about the way the load is balanced or moves once it’s up in the air. Chances are, using an engineered below-the-hook lifting device can improve the efficiency and safety of your lifts and help secure your loads.</p>

What do you do if you feel like your crane isn’t performing as efficiently or as safely as you think it can? Maybe it takes too long to secure or remove each load using traditional rigging slings and hardware. Or, maybe something just doesn’t seem right about the way the load is balanced or moves once it’s up in the air. Chances are, using an engineered below-the-hook lifting device can improve the efficiency and safety of your lifts and help secure your loads.

What is a Below-the-Hook Lifting Device?

In simple terms, the American Society of Mechanical Engineers (ASME) states that a below-the-hook lifting device is “a device used for attaching a load to a hoist. The device may contain components such as slings, hooks, and rigging hardware…” In other words, a below-the-hook (BTH) lifting device is a tool or mechanical device that attaches to a crane or other lifting apparatus, and grabs and secures a load so that it can be moved safely from one location to another.

Custom-built below-the-hook devices are very common. Engineered lifting devices are built for picking and moving a very specific load due to its size, shape, or center of gravity. A manufacturer will partner with their customer to develop a completely new device from scratch or may modify an existing product design for their specific lifting needs.

Most manufacturers also carry lifting devices in standard sizes and configurations for common lifting applications like:

- Lifting and moving of pipes or bars

- Lifting and stacking coils

- Lifting, moving, and stacking of sheets, plates, or other horizontally-stacked materials

- Lifting and moving pallets

- Lifting and moving of structural shapes

Below-the-hook lifting devices are most often mechanical, but can also be operated electronically, hydraulically, or pneumatically, as well—with special controls engineered into the design of the product to operate claws, tongs, hooks, or latches.

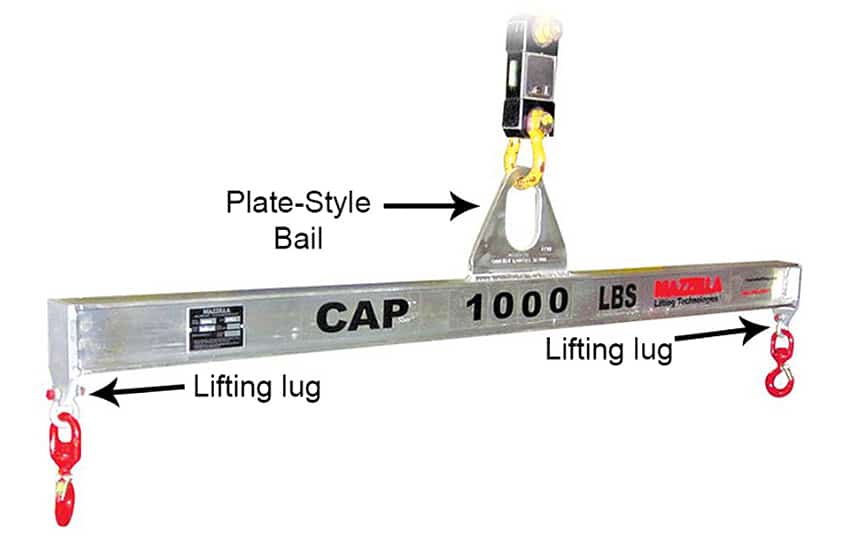

What Are the Components of a Below-the-Hook Lifting Device?

In order to fully understand a below-the-hook lifting device, let’s break down some of the common components to see how they affect the performance and design of each device.

Bail

The opening or attachment point where the crane hook engages. Bails can be plate style or pin style.

Lifting Lug

An attachment point on a lifting device where the rigging equipment will connect via a shackle or hook.

Gusset

A reinforcing plate welded on to the device to add strength to an area of extreme stress or usage.

Latch

Device used to hold a lifter in an open or closed position.

Why Should You Use a Below-the-Hook Lifting Device?

Safety and efficiency are the two main reasons for using a below-the-hook lifting device in conjunction with your crane and rigging equipment. Sometimes, using a traditional wire rope sling, alloy chain sling, or synthetic sling just isn’t enough to safely and securely move a load from one location to another.

Often, a customer who is already using some type of lifting sling, or a variety of slings, will approach a manufacturer to develop a custom lifting device for their lifting application. It may be because it’s taking too long to secure their load using traditional rigging, or it may be due to the size, shape, or weight of the load and they don’t feel that their current method is the safest or most effective.

An accident or near miss may be another reason to convert to a custom below-the-hook lifting solution. If the materials you are trying to move just don’t look right when they get up into the air, or you don’t feel that your load is secure enough—or worse yet, you’ve actually experienced a rigging failure—then it’s probably time to consult with an expert and see if they can help engineer a solution to keep your employees safe and your loads secure.

Often, lifting points on a load are there because the manufacturer found that location to be convenient—not because they’re the safest, most balanced locations for lifting and maneuvering.

Instead of trying to get creative using slings, a custom lifting device can be made to provide sufficient load control. A load that is unbalanced with an offset center of gravity, is a perfect candidate for a below-the-hook lifting product because this custom lifter can be designed with an adjustable bail to re-balance the load.

Keep in mind, you may be lifting valuable and expensive equipment or materials, and if that load isn’t secure, it could potentially injure your employees or cost your business in damaged goods.

What are the Different Types of Below-the-Hook Lifting Devices?

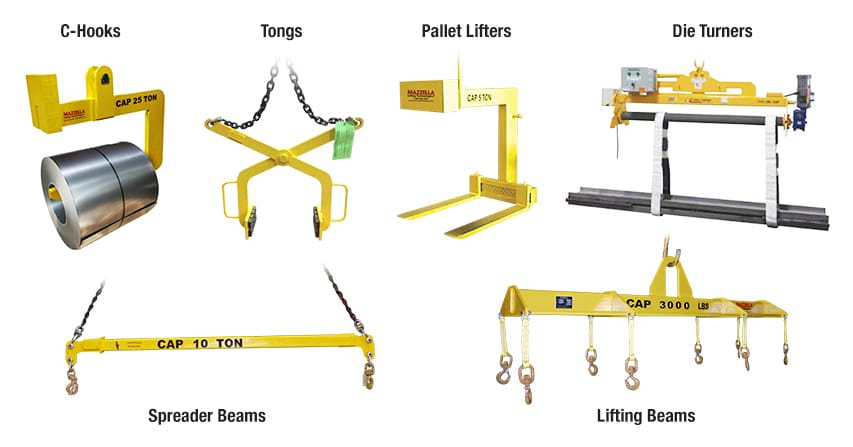

A variety of different application-specific, attachments can be added to a crane’s hoist to handle the lifting or positioning of different loads. These can include:

Coil Hook

A lifting device that enables the lifting of a coil through its inner diameter, in a vertical or horizontal orientation. A motorized hook rotator attaches to the bottom block of a hoist and powers the rotation of the hook for additional load control.

Gripping Lifters

Use either friction or indentation-causing pressure to hold a load. Tong grabs or clamps utilize a scissor-type action to grip a load. Coil grabs grasp the outer diameter of a coil via tongs or gripping mechanisms to lift or turn it.

Mechanical Lifters

Composed of two or more rigid parts which move in tandem for attaching a load to a hoisting device.

Sheet Lifters

Use two claws to grab a load of sheet metal or wood by wrapping around the edges. A lip on the lower portion of the claws prevents the sheet from falling out of the lifter.

Pallet Lifters

Use forks to lift pallets from underneath.

Beams

A load supporting lifter typically made from structural shapes or fabricated metal and are suspended from a hoist/crane to provide one or multiple load lifting points for better security and control of the load’s movement.

- Lifting Beams – They consist of a long beam with one top bail and two or more load lifting points. Lifting beams are generally heavier and more expensive than spreader bars. The main benefit of lifting beams is the substantially-reduced headroom required to perform the lift.

- Spreader Beams – They have top rigging consisting of wire rope slings, chain slings, or synthetic slings to better assist in load balance and control. They also tend to be smaller in design than lifting beams.

- Spreader Bars – They consist of a long bar that’s function is to hold a sling apart to the lifting distance. Spreader bars are lighter and cost less than their lifting beam counterparts. However, they require much more headroom to make the lift than a lifting beam.

Die Turners

Used to rotate or turn large dies safely instead of “flipping” them over with a crane and rigging equipment.

Vacuum Lifters

Utilize an electric-powered extraction pump and sealed pads to create a vacuum to attach the lifter to an object.

Magnet Lifts

Used to carry or release flat or round ferrous objects with or without an electrical power supply.

Drum Turners

Used to turn over drums for filling and emptying.

Wrapping it up

We hope that this lesson was able to give you a basic understanding of what a below-the-hook lifting device is and why you might consider using one in conjunction with your overhead crane system for your specific lifting needs.

A BTH lifting device can be as simple as a standard spreader beam used to evenly distribute the weight of a load, or it can be a more complex, totally customized spreader beam with built-in coil hooks to lift and move multiple coils at once.

The major benefits of using a below-the-hook lifter are that it can increase the efficiency of your lifts, allowing you to make more lifts per shift, and also properly secure the load so that it can be transported safely.