6-5 | Disposal of Damaged / Failed Slings

<p>When performing a metal mesh sling inspection, you’ll want to identify a potential issue and take action on it before the sling is connected to any rigging hardware. Broken welds, broken wires, visible distortion, or damage to either fitting can compromise the strength and lifting capabilities of the sling when under load. Therefore, the sling must be removed from service immediately.</p>

When performing a metal mesh sling inspection, you’ll want to identify a potential issue and take action on it before the sling is connected to any rigging hardware. Broken welds, broken wires, visible distortion, or damage to either fitting can compromise the strength and lifting capabilities of the sling when under load. Therefore, the sling must be removed from service immediately.

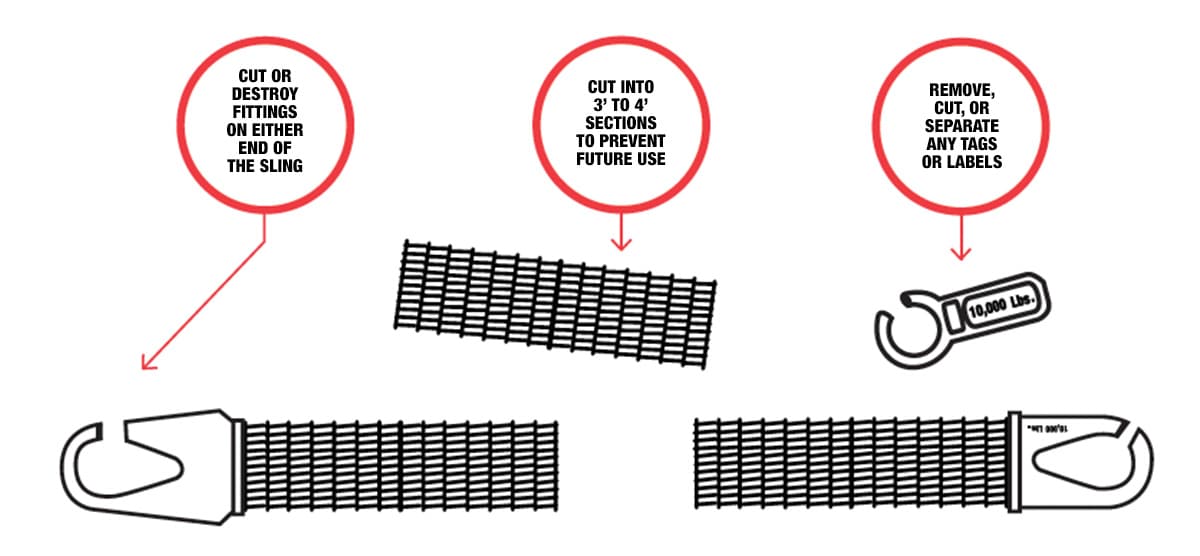

If it is determined that a metal mesh sling meets the removal from service criteria, then the following actions need to be taken to discard and render the sling unusable:

- Cut into smaller 3’ to 4’ sections to prevent use of any salvageable lengths of the sling

- Use a chop saw or torch to cut or destroy fittings on either end of the sling

- Use proper PPE when handling pieces of cut wires—cutting can leave sharp edges and metal burrs

- Remove, or separate, any tags and labels

- Place scrap into your facility’s metal recycling bins and coordinate pickup or delivery