1-3 | Basic Inspection Criteria

The goal of a sling inspection is to evaluate remaining strength in a sling which has been used previously to determine if it is suitable for continued use. When inspecting wire rope slings, daily visual inspections are intended to detect serious damage or deterioration which would weaken the sling.

This inspection is usually performed by the person using the sling in a day-to-day job. The user should look for obvious things, such as broken wires, kinks, crushing, broken attachments, severe corrosion, etc. Any deterioration of the sling which could result in appreciable loss of original strength should be carefully noted and determination made on whether further use would constitute a safety hazard.

ASME B30.9 standards specify that a wire rope sling shall be removed from service immediately if any of the following conditions are present:

Missing or Illegible Sling Identification

If the tag is missing or illegible, the inspector should remove the sling from service and send it to the manufacturer for current or updated certification, tagging, and testing.

Broken Wires

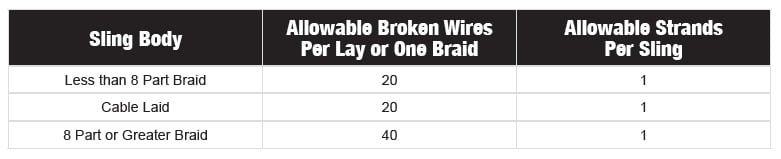

For strand-laid grommets and single-part slings, ten randomly distributed broken wires in one rope lay, or five broken wires in one strand in one rope lay. For cable laid, cable laid grommets and multi-part slings, use the following:

Distortion

Kinking, crushing, birdcaging or other damage which distorts the rope structure. The main thing to look for is wires or strands that are pushed out of their original positions in the rope.

Heat Damage

Any metallic discoloration, fusing of wires or loss of internal lubricant caused by exposure to heat.

Damaged End Attachments

Cracked, bent or broken end fittings caused by abuse, wear or damage.

Bent Hooks

No more than 5 percent over the normal throat openings, measured at the narrowest point from the plane of the unbent hook (see ASME B30.10 Hooks).

Corrosion

Severe corrosion of the rope or end attachments which has caused pitting or binding of wires should be cause for replacing the sling. Light surface rust does not substantially affect strength of a sling.

Pulled Eye Splices

Any evidence that eye splices have slipped, tucked strands have moved or pressed sleeves show serious damage may be sufficient cause to reject a sling.

Unbalance

A very common cause of damage is the kink which results from pulling through a loop while using a sling, thus causing wires and strands to be deformed and pushed out of their original position. This unbalances the sling, reducing its strength.

Kinks

Tightened loops with permanent strand distortion that result from improper handling when a rope is being installed or while in service. A kink happens when a loop is permitted to form and then is pulled down tight, causing permanent distortion of the strands. The damage is irreparable and the sling must be taken out of service.

Doglegs

Permanent bends caused by improper use or handling. If the dogleg is severe, the sling must be removed from service. If the dogleg is minor, (exhibiting no strand distortion) and cannot be observed when the sling is under tension, the area of the minor dogleg should be marked for observation and the sling can remain in service.