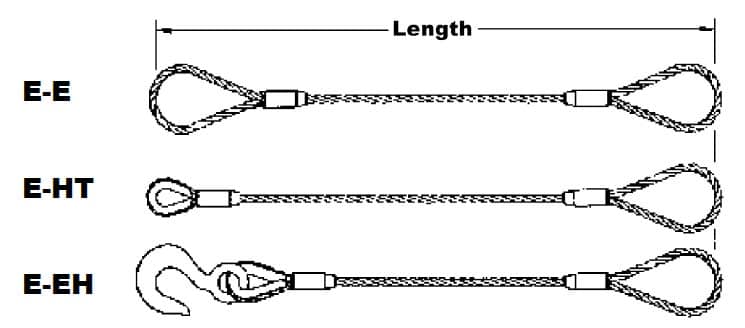

Single-Part Body Mechanically Spliced Wire Rope Slings

The eyes of a singe-part mechanically spliced wire rope sling are formed using the flemish eye splice. The ends are secured by pressing a metal sleeve over the ends of the strands of the splice.

The eyes of a singe-part mechanically spliced wire rope sling are formed using the flemish eye splice. The ends are secured by pressing a metal sleeve over the ends of the strands of the splice. Pull is directly along the centerline of rope and eye. This gives most efficient use of rope capacity and is economical.

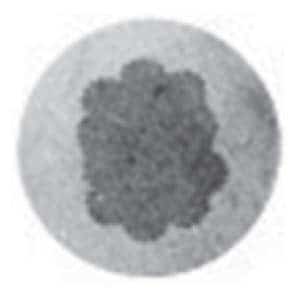

Swaging Provides Positive Grip

This cutaway of a metal sleeve strands, swaged onto a splice shows how metal “flows” into valleys between strands to positively prevent ends from unlaying when the sling is used within its rated capacity.

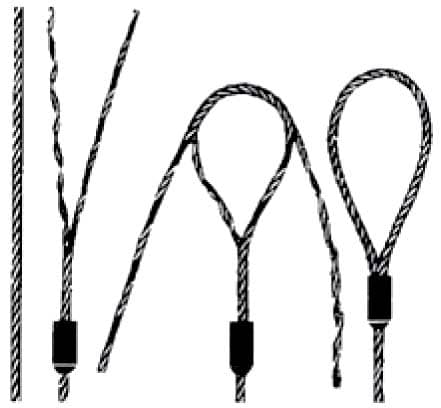

Flemish Eye Splice

In the standard flemish eye mechanical splice, the rope is separated into two parts: 3 adjacent strands and 3 adjacent strands and core. These two parts are then re-laid back in opposite directions to form an eye and the ends are secured with a swaged metal sleeve.

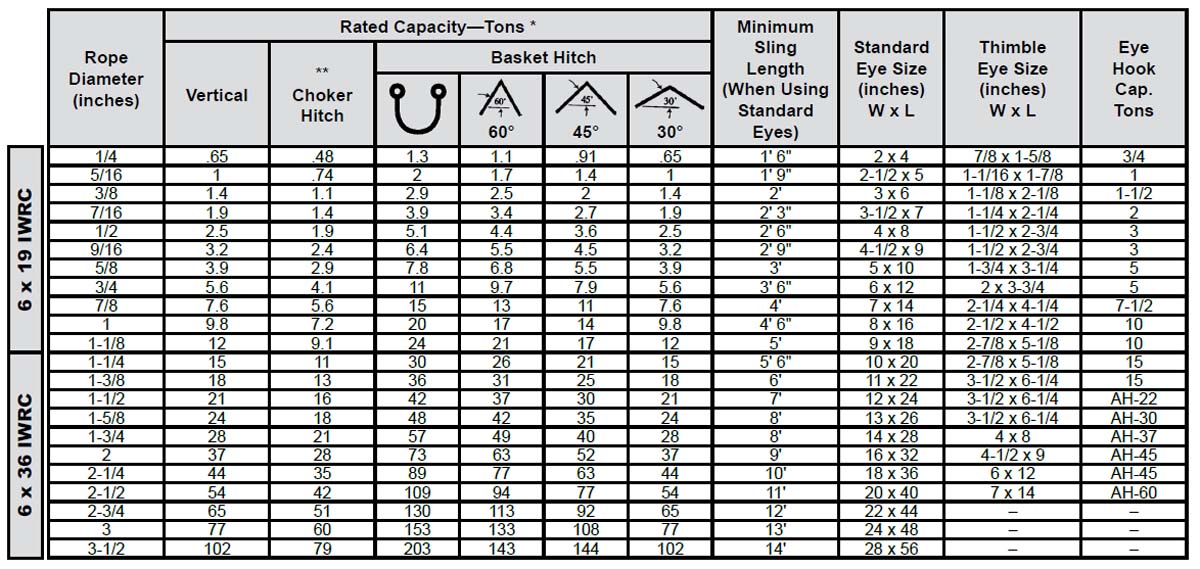

Rated Capacities based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

Rated Capacities based on design factor of 5.

** See Choker Hitch Rated Capacity Adjustment. Sling angles less than 30 degrees shall not be used.

Above capacities based on EIP rope.