The Difference Between C-Hooks and Coil Lifters: Which One’s Right for You?

In warehouses, factories, and manufacturing sites across the country, there’s a good chance you’ll find coil hooks (commonly called c-hooks) and coil lifters on site. With industries relying heavily on steel, a device is needed to lift and move steel rolls—sometimes weighing several tons—from one place to another.

You may be building a new facility, or you need to replace old, outdated lifting devices. Whatever it is, the process of deciding between a c-hook or coil lifter can be confusing. And while they’re popular, it’s common for these devices to be put in the wrong applications, which means you and your organization aren’t getting the most out of your investment.

At Mazzella, we engineer, manufacture, and inspect c-hooks and coil lifters for a wide range of industries.

This blog will help answer important questions you may have as you’re making your decision, including:

- Why would I use a c-hook or coil lifter instead of traditional lifting slings?

- What environment is best for each?

- What affects the pricing of a c-hook or coil lifter?

What Do C-Hooks & Coil Lifters Do?

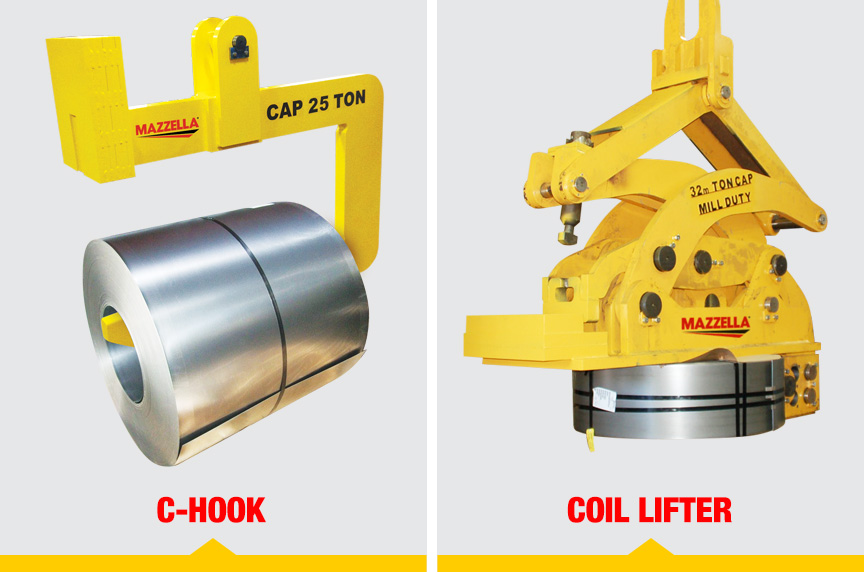

While they have different names and designs, c-hooks and coil lifters essentially have the same function: lift and move steel coils varying in size and length.

Organizations that invest in c-hooks and coil lifters are looking to:

- Avoid coil edge contact

- Keep the material safe from damage

- Accommodate various coil widths

- Increase efficiency

- Improve employee safety

These lifting devices lift the coil through its inner diameter. From there, a motorized hook rotator could be attached to the bottom block of a hoist, powering the rotation of the hook for additional load control.

Why Use C-Hooks or Coil Lifters Over Lifting Slings?

With some coils weighing several tons, manual labor is out of the question. This means you’ll need a below-the-hook lifting device to get the job done.

While lifting professionals love how affordable, lightweight, and ergonomic some lifting slings are, their material makes them susceptible to damage in intense environments. The sharp edges on metal coils also increase the chance of wear and tear on lifting slings and wire ropes.

With c-hooks, the pad on the bottom is rounded off to help support the metal coil, making it an easier and safer alternative to employees reaching in, throwing a sling through the inner diameter, and feeding it up and over to a crane hook.

Not only does this improve employee safety, but the time to rig using a c-hook is fractional compared to using a lifting sling. Additionally, the customization we offer for our c-hooks and coil lifters ensures you’re meeting industry standards.

Some of the coil lifter models we manufacture include the:

- Basic Coil Lifter

- Narrow Arm Coil Lifter

- Close Stacking Coil Lifter

- Vertical Grab Coil Lifter

- Telescopic Two-sided Coil Lifter

Some of the c-hook models we manufacture include the:

- Narrow Coil C-Hook

- Dixon Coil Hook with Pivoting Wedge C-Hook

- Heavy Duty C-Hook

- Close Stacking C-Hook

What are the Best Applications for C-Hooks and Coil Lifters?

According to our below-the-hook specialists, steel processing plants and steel mills are the most common environments for c-hooks and coil lifters.

But truthfully, they’re found in all types of manufacturing sites relying on steel.

Are C-Hooks and Coil Lifters Easy to Operate?

Anytime you’re using a below-the-hook lifting device, you should have additional training for that specific tool. But our below-the-hook specialists say c-hooks and coil lifters— especially c-hooks—are relatively easy for crane operators to learn and operate.

While easy to operate, neither c-hooks nor coil lifters have built-in safety mechanisms, meaning the operator is solely responsible for avoiding equipment damage or serious injuries.

How are C-Hooks and Coil Lifters Different?

While both pick up a coil using its inner diameter, the big difference between c-hooks and coil lifters comes down to the positioning of the metal coil. Due to its shape, a c-hook would be the preferred device if the metal coil is horizontal. Since it has a greater lifting capacity than a coil lifter, c-hooks are commonly used for loading heavy coils onto a machine, a loading vehicle, or a production line.

Mazzella manufactures c-hook models for heavy duty applications that are designed to:

- Handle multiple slit coils, maximizing your handling efficiency

- Recess its counterweight to minimize interference with equipment or obstacles

- Counter balance to hang level when empty

With c-hooks, you need enough space between the coil and the surrounding area to get the hook attached to the inner diameter, making it a challenge if your facility has limited space.

Coil lifters are the more ergonomic option. Commonly found in warehouses, distribution centers, and processing facilities, a majority of coil lifters pick the coil up from a vertical position, making them ideal for stacking coils in tighter spaces. Some models, like the Narrow Aisle Coil Lifter, can pick up the coil from a horizontal position.

While great for maximizing your storage space, a lot of manufacturing facilities can’t use coil lifters, because they interfere with stamping machines and other equipment.

What Affects the Pricing of C-Hooks & Coil Lifters?

Capacity and coil size are the biggest factors that affect the pricing of c-hooks and coil lifters. Those with a larger capacity require more material and labor, driving the price up.

For the most part, c-hooks and coil lifters have comparable price ranges. Devices with 1- or 2-ton capacities are in the $2,000–$5,000 range, whereas those with 20- to 50-ton capacities are between $20,000 and $50,000.

Additionally, customized additions like a T-handle, which helps operators better guide the coil, can increase the final price.

Can You Use Magnets to Pick Up Metal Coils?

Recently, magnetic lifting devices have become a popular choice for specialized applications. Not only do they reduce potential coil damage, but they can also lift coils from a vertical or horizontal position.

The problem? Magnetic coil lifters are significantly more expensive than c-hooks or coil lifters, with some being in the $150,000–$200,000 range. Not only do they have a higher price tag, but magnetic lifters also need a high amount of electricity to operate.

There are many magnetic handling manufacturers in the United States and worldwide, including:

How Do I Know Which is Right for Me: C-Hooks or Coil Lifters?

There are many factors to consider when purchasing a c-hook or coil lifter. During that process, review what environment it will operate in, how much space is available at your worksite, and the capacity and size of your coils.

We understand that there are many options out on the market, and it can be confusing to determine which one is right for your organization. Mazzella produces both standard and custom-designed c-hooks and coil lifters to fit your needs. Visit our product page to get more information on the different applications for each type.

Want to discuss c-hooks, coil lifters, and other below-the-hook devices with an expert? Contact one of our lifting and rigging specialists today.

Below-the-Hook Lifting Devices

We have more than 65 years of experience in designing and developing custom engineered products, below-the-hook lifting devices, and lifting attachments for use with all types of cranes.

On-staff engineering and our commitment to ISO 9001: 2015 guides us to continued success in quality products and processes.

Copyright 2024. Mazzella Companies.