What Is the Uni-Life Track™ Fall Protection System?

Designed by Columbus McKinnon, the Uni-Life Track™ Fall Protection System is an aluminum fall arrest system that can be used in a variety of industries and applications. Our article breaks down pricing, key components, and how it improves rescue plans and overall worker safety.

Any worker, regardless of their experience and training, is at serious risk when working at height. All it takes is one slip, trip, or fall for them to experience life-altering injuries. Mistakes happen, and that’s why having the right engineered fall protection system in place is worth the investment.

And whether you work in general manufacturing, transportation, or entertainment, a fixed track fall arrest system can be a great addition to your applications. One of the best—and newest—options on the market is Columbus McKinnon’s Uni-Life Track™ Fall Protection System. What makes this system unique, and is it a good solution for your fall protection needs?

Mazzella’s Fall Protection division has been a leader in inspecting, installing, and upgrading engineered fall protection systems for companies of all sizes and industries, and we understand the time and resources it takes to invest in an engineered fall arrest system.

To help you during your research process, our article will break down everything you need to know about a Uni-Life Track™ System, including:

- What Is the Uni-Life Track™ Fall Protection System?

- What are the Key Components of a Uni-Life Track™ System?

- What Industries Could Use a Uni-Life System?

- Why Choose an Aluminum Fall Arrest System Over Steel?

- What Is the Uni-Life’s Inspection Criteria?

- What are the Benefits of a Uni-Life Track™ Fall Protection System?

- What Affects the Uni-Life Track™ System’s Pricing?

- How Can You Purchase the Uni-Life Track™ Fall Protection System?

What Is the Uni-Life Track™ Fall Protection System?

The engineers at Unified Industries, a Columbus McKinnon brand, saw a need for an aluminum fall arrest system, which offers users a lighter and less corrosive alternative to steel systems. From here, the Uni-Life Track™ Fall Protection System was born.

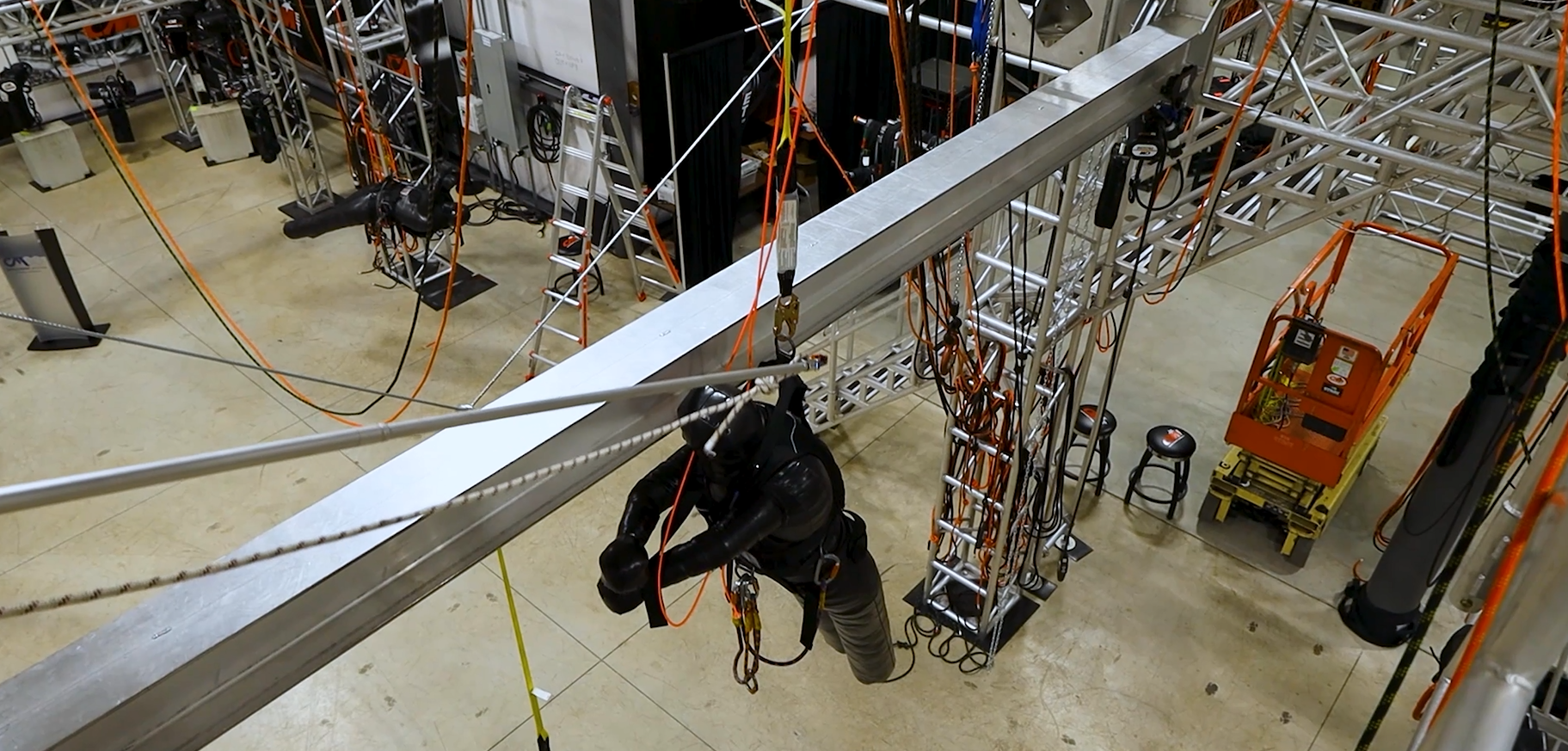

The Uni-Life is a fixed track system designed for use in general industry and entertainment environments for the fall arrest of personnel working at height.

What are the Key Components of a Uni-Life Track™ System?

All Uni-Life Track™ systems use the following components:

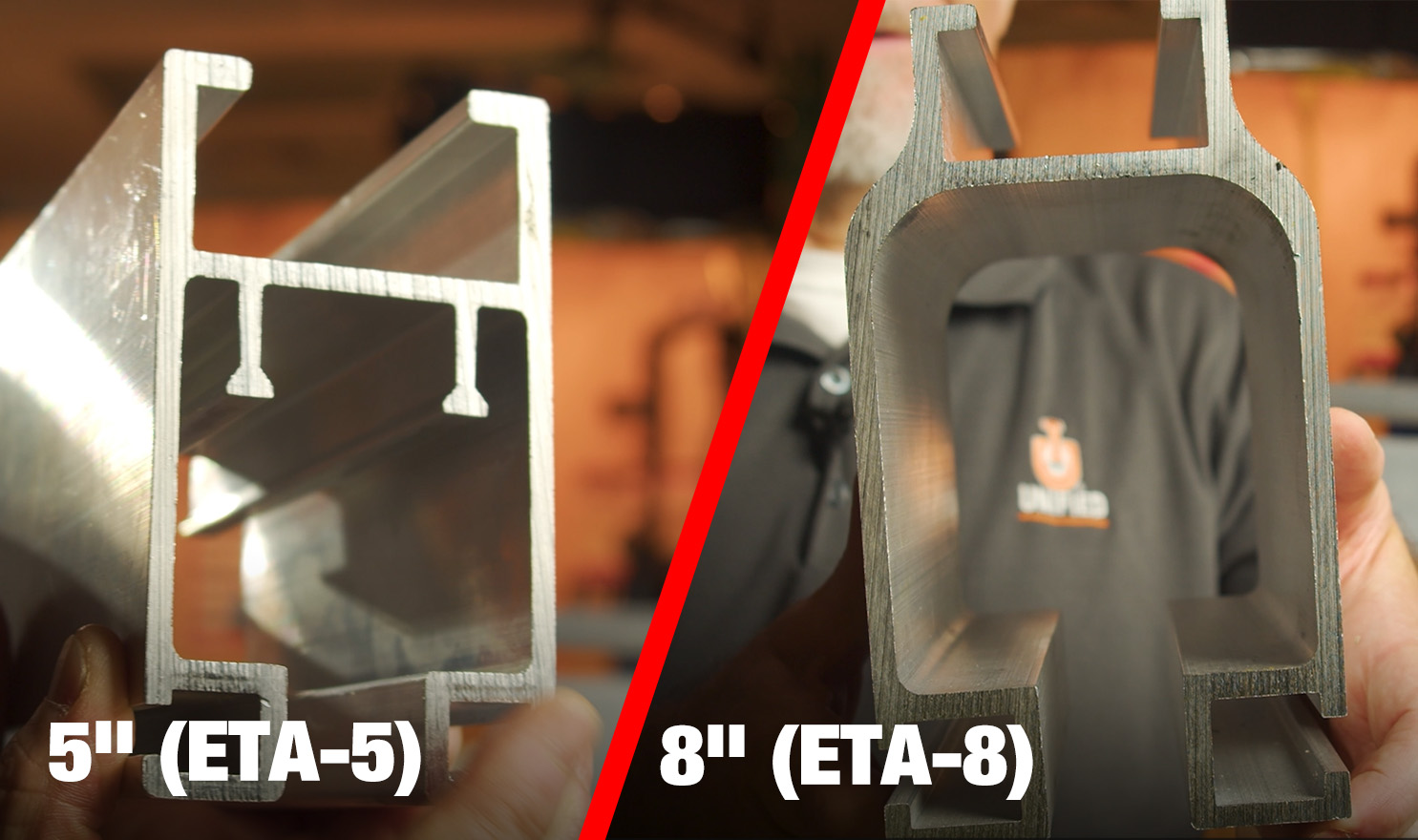

Aluminum Rail Profiles

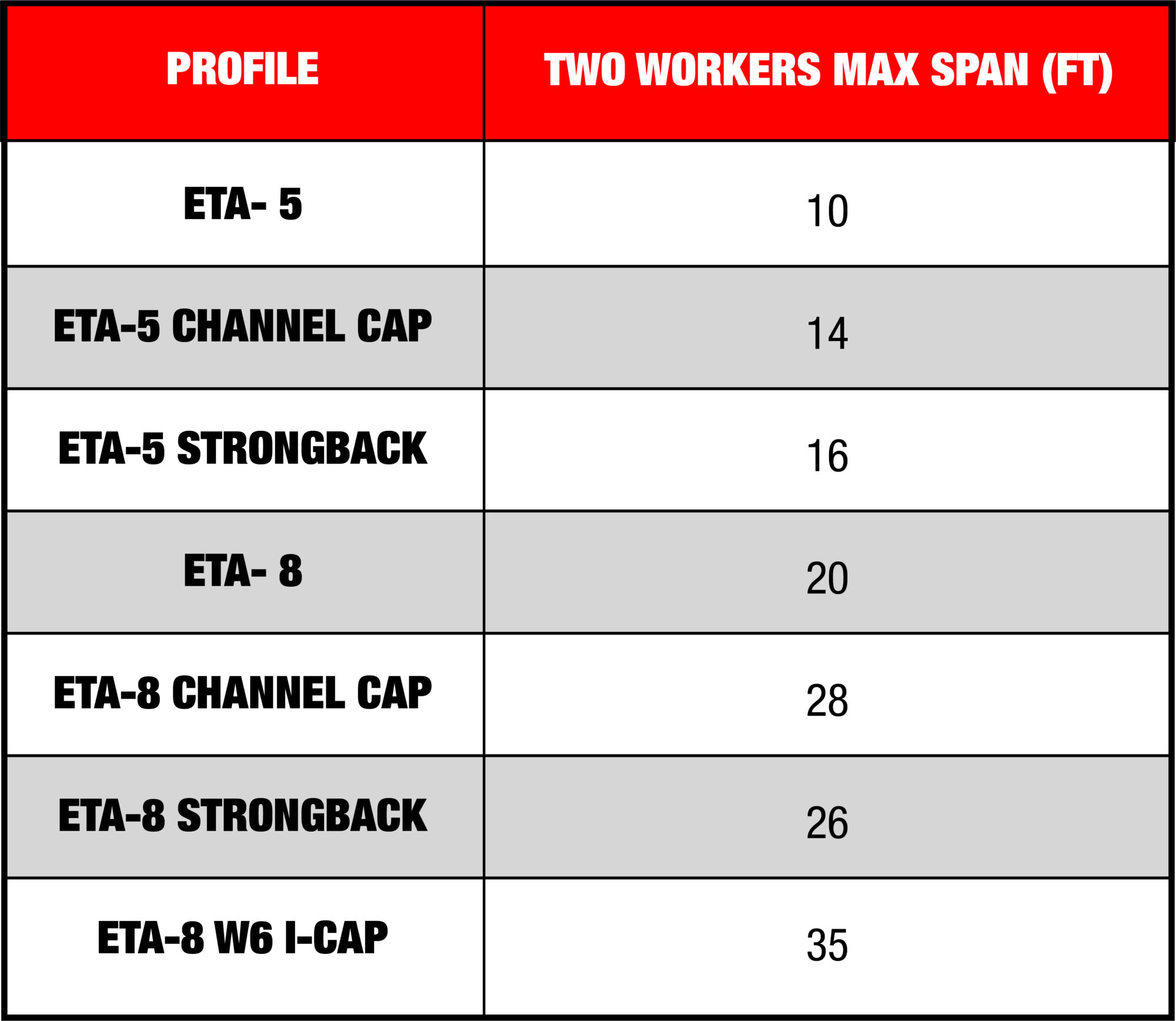

Available in 5” (ETA-5) and 8″ (ETA-8) models, the enclosed track aluminum (ETA) profiles have an enclosed track to ensure a clean rolling surface for the trolley. The biggest difference between the two is the ETA-8 model can accommodate curves in the track, and the ETA-5 model can’t.

ETA-5 systems are lighter and easier to maneuver, making them the better choice for entertainment applications. Conversely, the ETA-8 model is great for heavy duty applications. And while both can support multiple workers, the ETA-8 model can support more.

Trolleys

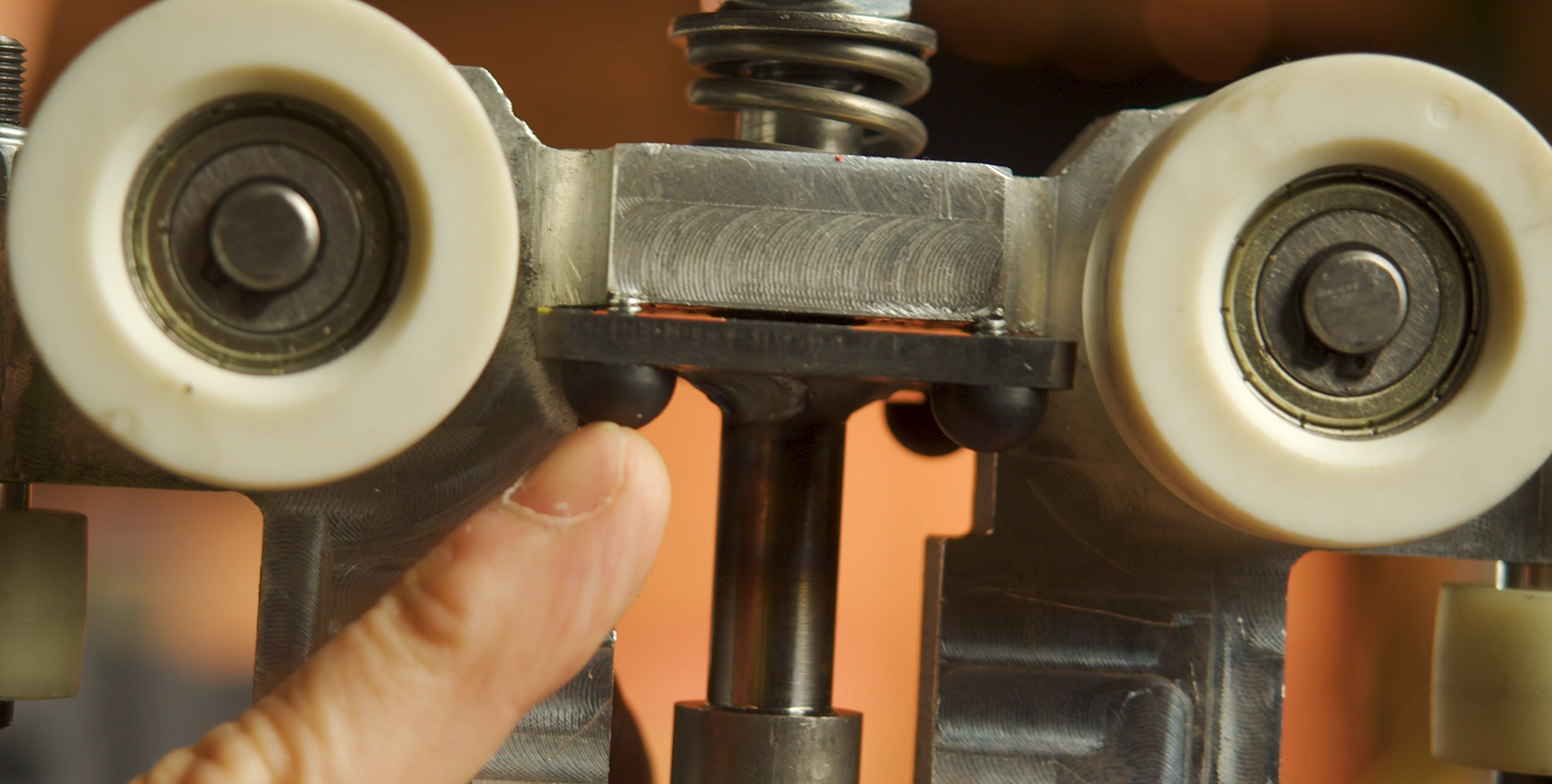

Trolleys have a low-roll resistance that makes for seamless tracking above the operator. If a fall occurs, the trolley has a braking mechanism which will prevent the workers’ forward momentum from carrying them into dangerous areas and obstacles. The braking mechanism will trigger when anywhere between 25-50 lbs. of force is applied to the system.

One of the more profound differences between the Uni-Life and other track systems is the trolley’s design.

CM trolleys have a rubber pad which contacts the rolling surface, whereas other systems have “teeth” that engages with the steel. This teeth design makes it harder to get an incapacitated worker to a safe area. With the Uni-Life system, the brake will remain engaged, but with some friction that allows for an easier rescue effort by allowing for a member to pull the injured worker out of harm’s way form a safe distance using a poll or hook.

Hangers and End Stops

Uni-Life systems have multiple hanger options for industrial and entertainment applications: quick coupler hangers, block hangers, and adjustable block hangers.

All hanger options include an 8′ safety cable with rod ends in the event of a catastrophic failure, but these can be customized to fit certain application needs.

What Industries Could Use a Uni-Life System?

Uni-Life Track systems were designed with multiple industries and applications in mind. Any industry working at height (4’ or greater for general industry; 6’ for construction) could benefit from a Uni-Life Track™ System.

They can be used by maintenance teams working in a manufacturing environment. They can be used in loading docks, whether it be for a barge or a truck. They can also be used in an aerospace facility for wing maintenance and inspections.

Uni-Life Track’s have also proven to be very popular in the entertainment industry for:

- Stage or set fixing

- Repairing video walls

- Maintaining stage assemblies

- Lighting

- Set design

- Facilitate production

In one example, the Uni-Life was used to help a technician replace a large section of a video wall. In another example, the system was used to improve worker safety on a major barge on the Mississippi River.

Uni-Life Track’s are also great for any low-headroom applications, as its fixed anchorage system does not sag, unlike a wire rope system.

Why Choose an Aluminum Fall Arrest System Over Steel?

While steel is the most common material used for rail and track based systems, there are plenty of benefits to picking aluminum. First, aluminum is much lighter than steel, making it easy to handle and move around a facility. This is one of the reasons why it’s popular in entertainment applications.

Aluminum systems are also less likely to corrode, which makes them ideal to use in any outdoor environment or high-moisture applications. Aluminum systems offer these benefits all while being in a relatively similar price range to steel systems.

While Columbus McKinnon uses steel hardware on the hanger blocks, they can provide zinc plated hardware, or black oxide coating, to withstand corrosion.

What Is the Uni-Life’s Inspection Criteria?

You don’t need to rely on Unified Industries or Columbus McKinnon to inspect your Uni-Life Track™. Any competent or qualified person at your facility—as established by relevant OSHA and ASME standards—can, in most states, inspect the system.

Industry Standards

Uni-Life systems were built to meet or exceed requirements for several regulatory requirements and industry standards, including:

- OSHA 1910.140 Personal Fall Protection Systems (subpart I) & 1926.501

- ANSI/ASSP Z359.2-2023 Fall Protection Program Requirements

- SPRAT: Safe Practices for Rope Access Work (sec. 12.1.1)

- IRATA: International Code of Practice (sec. 2.11.2.6)

What are the Benefits of a Uni-Life Track™ Fall Protection System?

Prevents Secondary Injuries

The Uni-Life Track’s fixed anchorage system greatly reduces fall clearance. This decreases the force exerted on a worker when they fall and reduces the likelihood of secondary injuries.

Simplifies Rescue Plans

When a worker falls and is suspended, the harness becomes a tourniquet to your femoral artery, cutting off circulation. Venous pooling, where the leg veins don’t allow blood to flow back to your heart, is a common injury that fallen workers face.

If not rescued in time while suspended at height, workers can even potentially experience a stroke or a pulmonary embolism. Consequently, every second counts, and having systems in place that simplify the rescue process can save lives.

Because the Uni-Life supports multiple trolleys, rescuers can easily reach incapacitated or injured workers. You can even perform a remote rescue using an extension pole from a safe location.

Furthermore, since the system reduces uncontrolled lateral motion, it positions the worker closer to the area they fell from and makes a self-rescue more likely.

Allows for Multiple Workers on a Job

As mentioned, Uni-Life Track™ has multiple connection points, allowing for more workers along the length of the system, helping to speed up processes.

Several Customization Offerings

You can work with Mazzella’s engineering team to customize your Uni-Life Track™ system with existing components and parts. One of the most popular customization offerings is having a curved rail system, although this is only available with the ETA-8 model.

And while all Uni-Life models come unpainted, the system can be anodized in a clear or black coating. They can also paint it any color you need for your application—just provide them with the Sherwin-Williams RAL number.

Less Frequent System Replacement

Other wire rope or synthetic horizontal lifeline systems require you to replace the entire system if a worker falls. If a fall occurs on the Uni-Life Track™, all you have to do is inspect the trolley and other system components for damage.

If no damage is found, you can still use the system, greatly reducing downtime and helping improve cost savings.

What Is the Uni-Life’s Weight Capacity?

Regarding fall protection, the rail and trolleys are rated at 310 lbs. per person at 900 lbs. of maximum arresting force (MAF). Each trolley can handle up to 310 lbs. at 900 lbs. MAF, regardless of whether it’s ETA-5 or ETA-8.

What Affects the Uni-Life Track™ System’s Pricing?

Multiple factors will affect the pricing of a Uni-Life system. One of the biggest factors is the rail’s profile size. Would you need an ETA-5 or ETA-8 rail system? Most Uni-Life systems will range anywhere from $50-$70 a foot, but add-ons, custom work, and modifications will increase the final price.

Each work environment has unique factors that will impact pricing, and you can work with a Mazzella representative to get a more accurate estimate.

How Can You Purchase the Uni-Life Track™ Fall Protection System?

With a unique design, great durability ratings, many modification offerings, and added safety features, the Uni-Life Track™ System is a reliable, diverse, and effective fall protection system for almost any industrial and entertainment application.

Like all Columbus McKinnon products, the Uni-Life is made from top-tier materials and proudly manufactured in the United States. Not only will investing in a fixed fall protection system improve worker safety, but it will also dramatically improve productivity and keep you compliant with any OSHA, ANSI, local, and state standards.

We hope you learned more about this fall protection system from our partners at Columbus McKinnon, and we encourage you to reach out to one of Mazzella’s Fall Protection Specialists if you have questions, to get a quote, or to learn more about other engineered solutions for your application.

At Mazzella, installing a fall protection system is a collaborative effort. Your engineers can work with Mazzella’s engineers to design systems that meet your unique needs.

Copyright 2024. Mazzella Companies.