PE Pre-Engineered Built-Up Hoists

Capacity: 5 tons to 40 tons

Service Class: Meets duty requirements through CMAA Class D Service

Industries: Heavy manufacturing, steel service, hot metal, aerospace, defense, foundries, paper mills

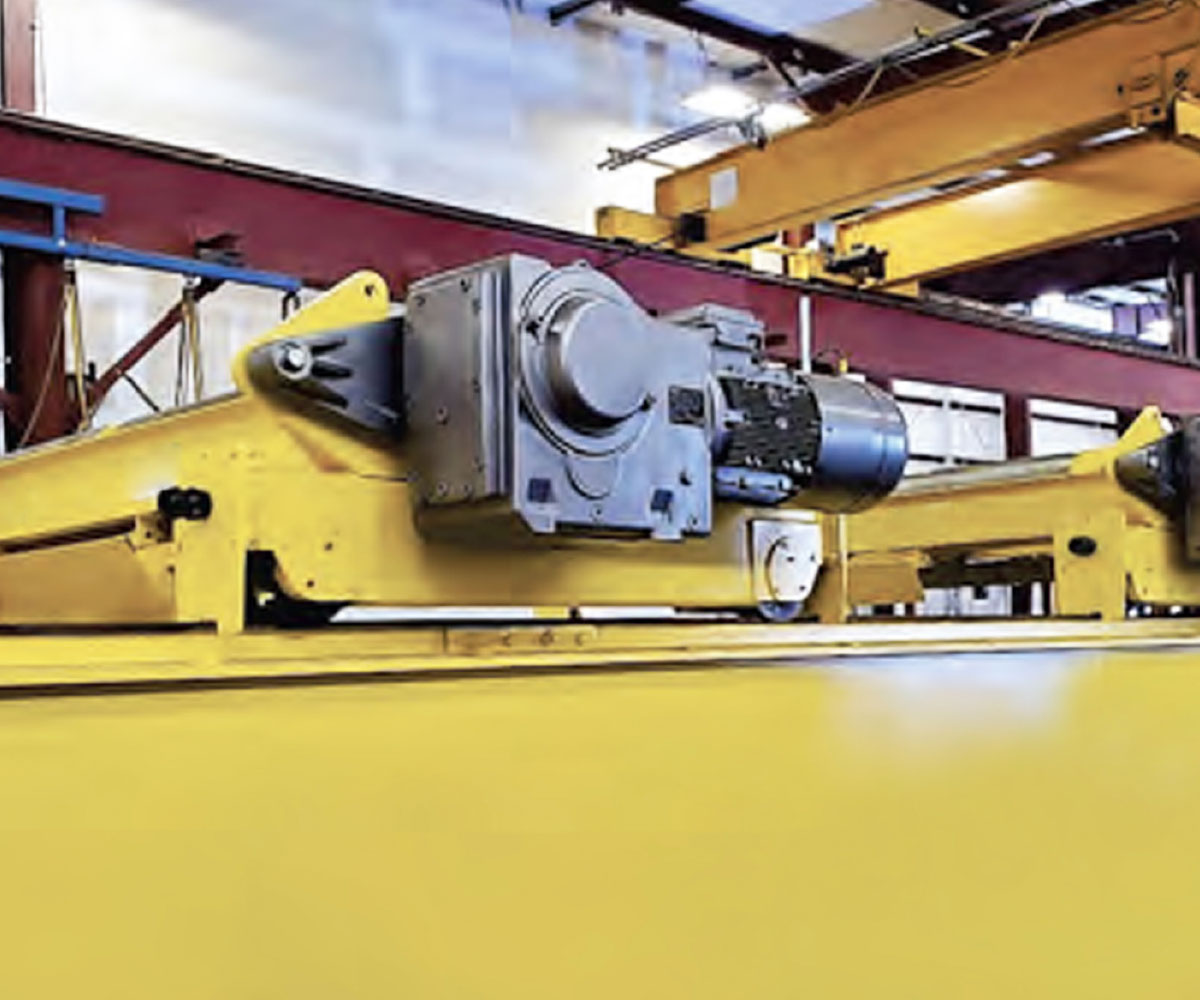

All Gearing: High-efficiency, helical, splash-lubricated, AGMA 11-13, case hardened (carburized) gears in leak-free cast iron housing with double lip oil seals.

Hoist Motor / Brake: 60-minute or continuous duty, cast iron frame, Class H insulation, TEFC (hoist and trolley) with integrally-mounted, DC-rectified disc brakes. 125% torque for hoist, 50% minimum torque for trolley.

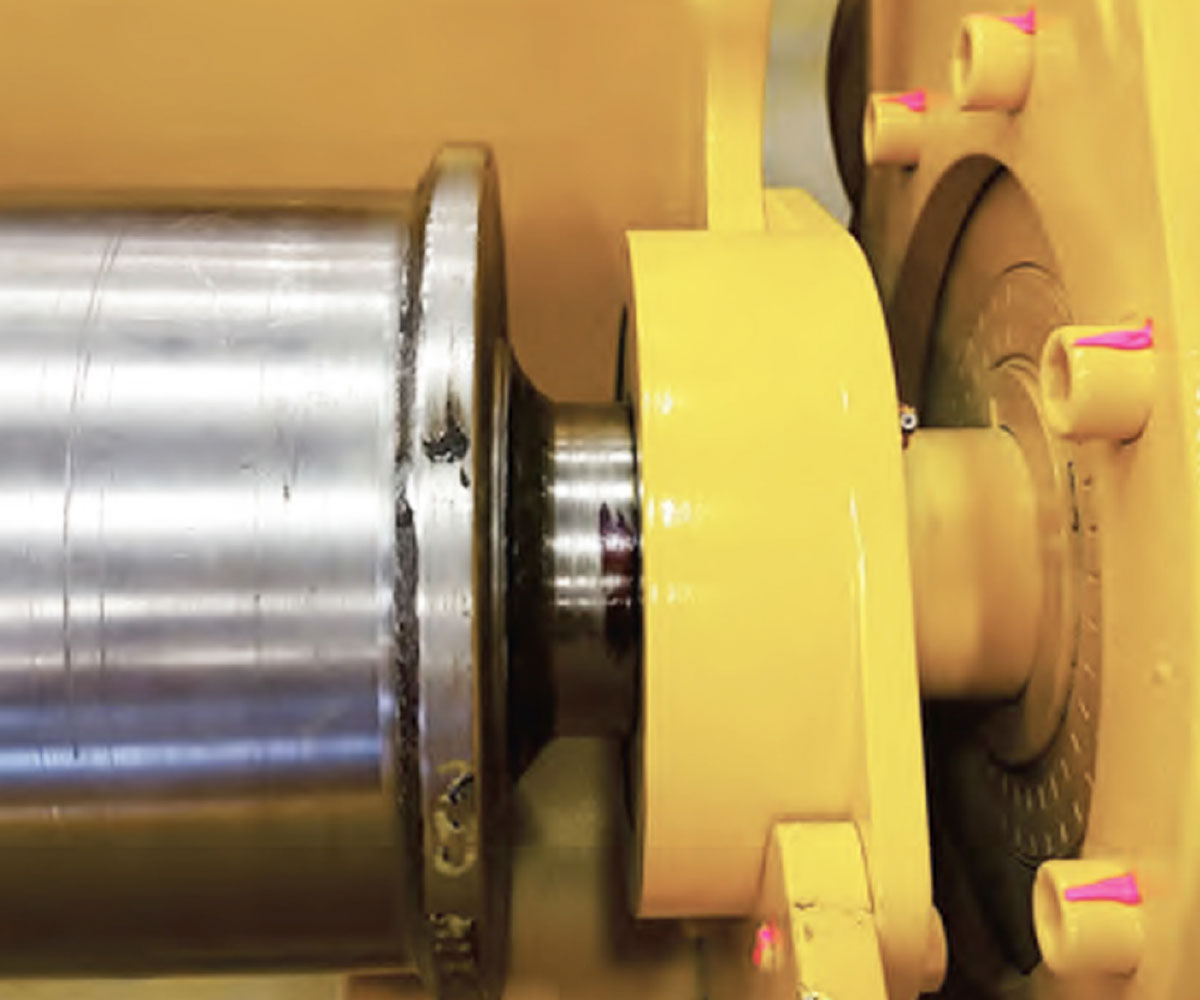

Wheels: Dual-flanged steel wheels with treads and flanges hardened to min. 425 BHN. Rotating axle supported in MCB type cartridge bearings bolted to machined seats at four corners of frame wheel, axle, and bearing assemblies can be rolled out for easy inspection or repair.

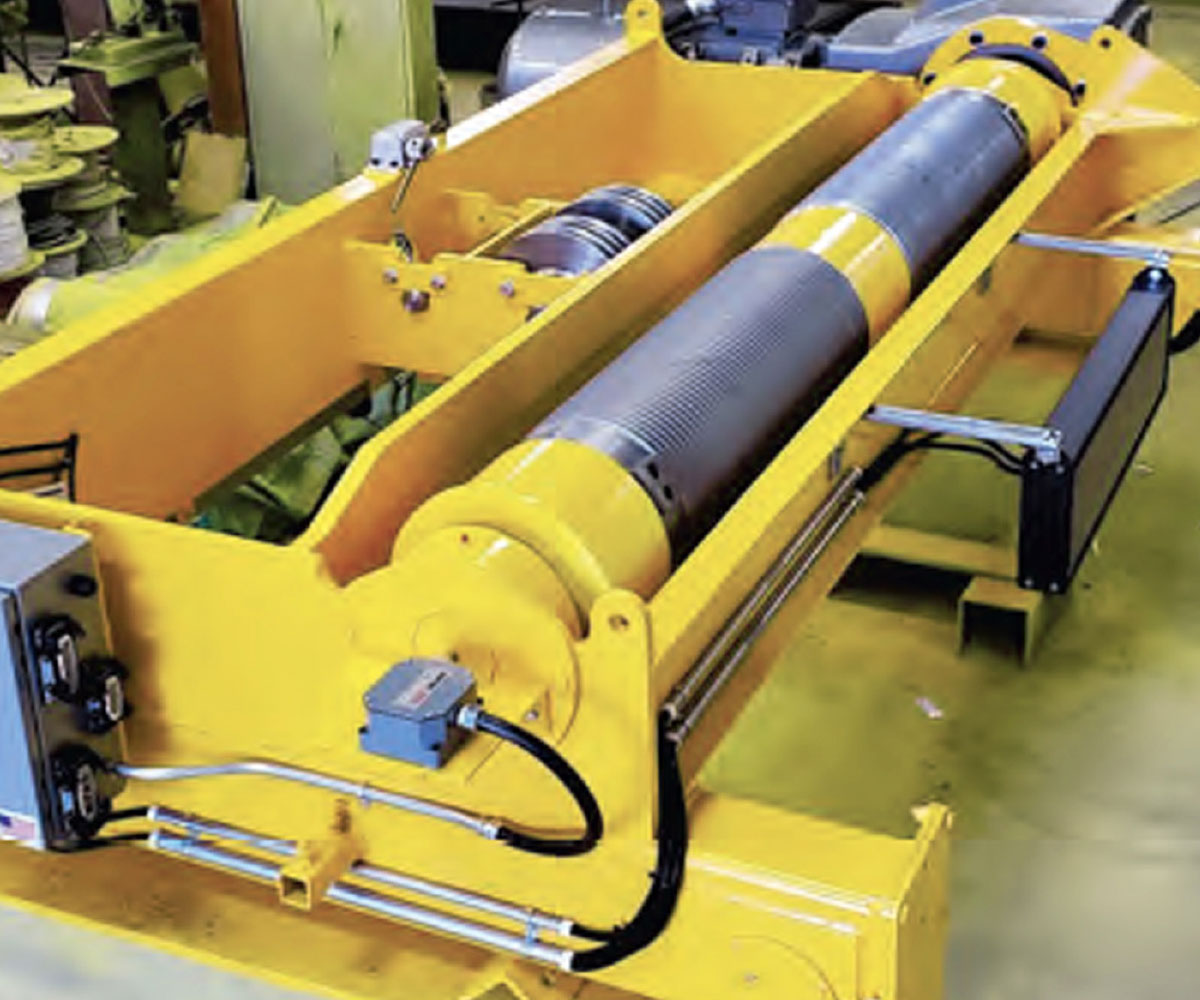

Drum / Reeving: Minimum 1/2 depth right-hand and left-hand grooved drum for true vertical lift. Minimum 20:1 drum to wire rope ratio. Can be larger dependent on capacity and speed requirements.

Trolley Hoist Frame: Open winch design, welded structural steel frame.

Upper Sheave Nest: Pin and keeper design, removable as an assembly from top by removing two bolts.

Limit Switch: Upper and lower adjustable geared limit switch plus back-up weight operated unit.

Trolley / Hoist Controls: Flux vector VFD hoisting, VFD trolley, 460/3/60.

Drum Bearings: Drum bearing each end to eliminate gearbox axial loading.

Commercially Available Components: Most components are readily available directly from component manufacturer. Original equipment part numbers available upon request.

Available Options:

- Alternate trolley speeds

- Outdoor weather service and protection

- Manual brake release

- Festoon tow arm

- Increased trolley gauge

- Class H motor insulation

- Other voltages

- TOL relays

- Power circuit limit switches

- Cable reels