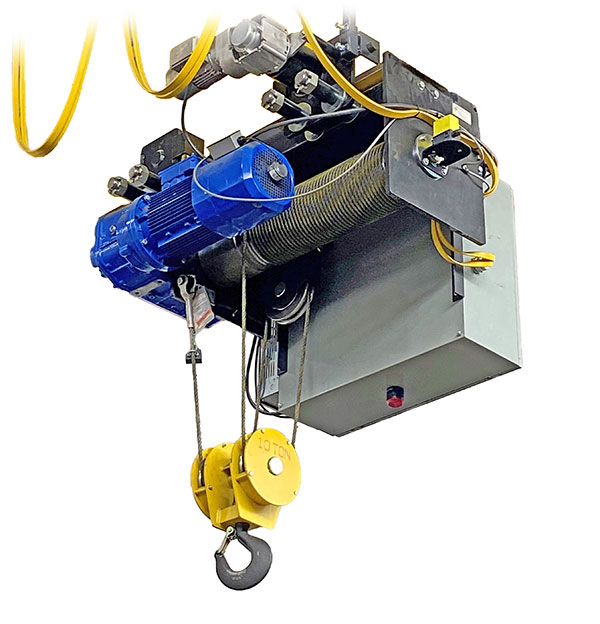

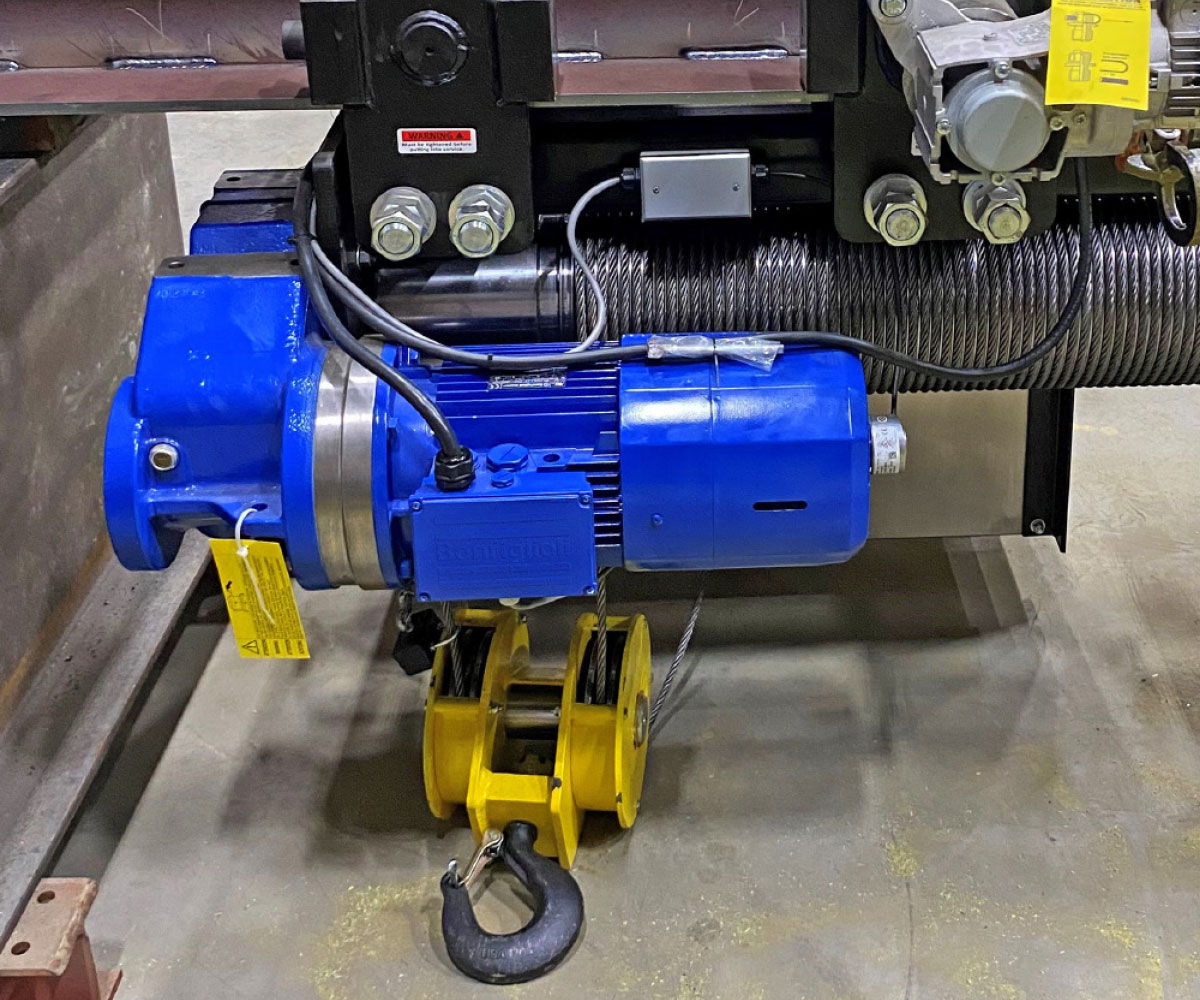

SE Standard Engineered Hoists for Cranes and Monorails

Capacity: 3, 5, 7.5, 10, and 15 tons

Service Class: Engineered and built to exceed ASME H4 Duty

- 2-speed or VFD hoist, VFD trolley

- Space-saving compact design

- Built for easy installation and maintenance

- One-year warranty

- Ask us about “The Beast” Series Dual-Brake SE Hoist for heavy-duty lifting applications!

Hoist and Trolley Gearing: Helical gearing operating in an oil bath.

Trolley Wheels: Crowned wheels for operation on flat and tapered flanges with lifetime lubricated sealed bearings.

Hoist and Trolley Motors: TEFC 30-minute squirrel cage motors with Class F insulation and adjustable DC brakes.

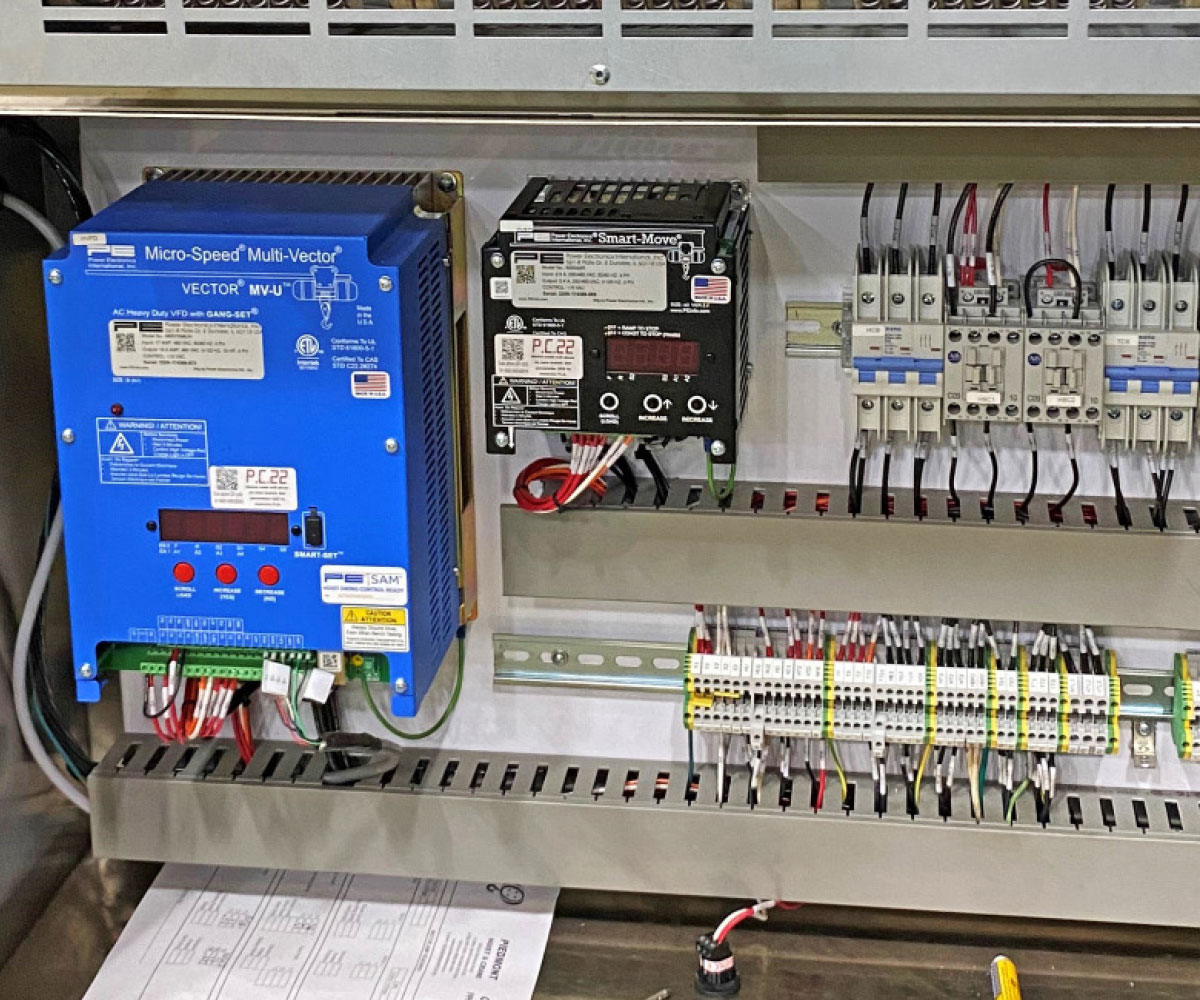

Hoist and Trolley Controls: Hoist and trolley controls mounted in a spacious NEMA 4/12 UL listed panel.

Limit Switches: Geared upper and lower limit switch plus a weight operated block activated limit switch.

Drum and Reeving: Minimum ½ depth grooving, single reeved with 18:1 drum to rope ratio.

Bottom Block: Welded steel bottom block with steel sheaves, continuous rotating load hook, and safety latch.

Available Options:

- Mainline contactor and transformer

- 2-speed hoist control

- Alternate trolley speeds

- IP65 brakes

- Wider trolley flange widths

- Overcapacity protection

- Pendant stations / radio

- Festoon arm

- UL panel labeling