Description

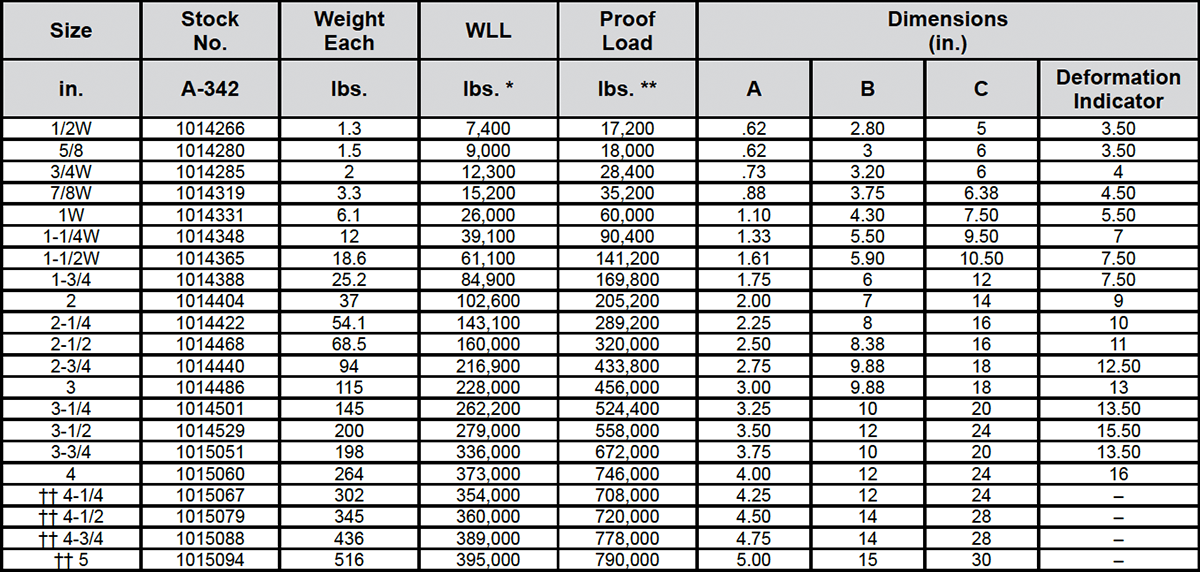

* Ultimate Load is 5 times the Working Load Limit. Based on single leg sling (in-line load), or resultant load on multiple legs with an included angle less than or equal to 120 degrees. Applications with wire rope and synthetic sling generally require a design factor of 5.

** Proof Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9.

†† Welded Master Link