Description

Universal – For Lifting in any Direction

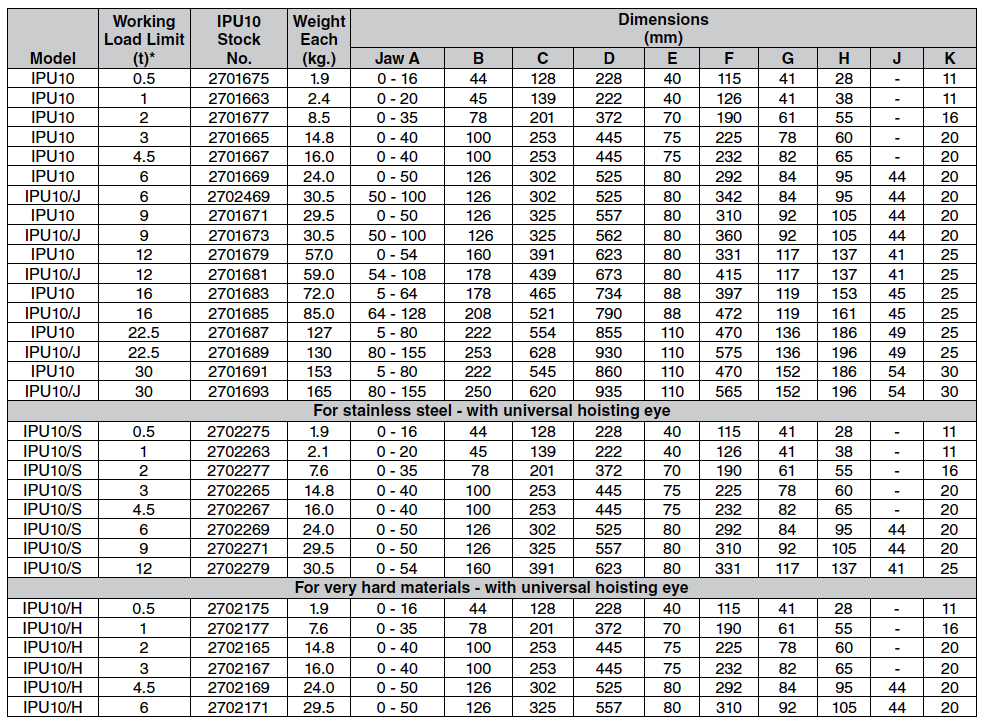

- Available in capacities of .5 thru 30 metric tons (Higher Working Load Limits are available upon request).

- Wide variety of jaw openings available: 0 to 155mm.

- Welded alloy steel body for strength and smaller size. Forged alloy components, where required.

- Individually Proof Tested to 2 times the Working Load Limit with certification.

- Company name (CrosbyIP), logo, Working Load Limit and jaw opening permanently stamped on body.

- Each product is individually serialized, with the serial number and Proof Load test date stamped on body. Serial number is included on the test certificate with maintenance and warranty logbook.

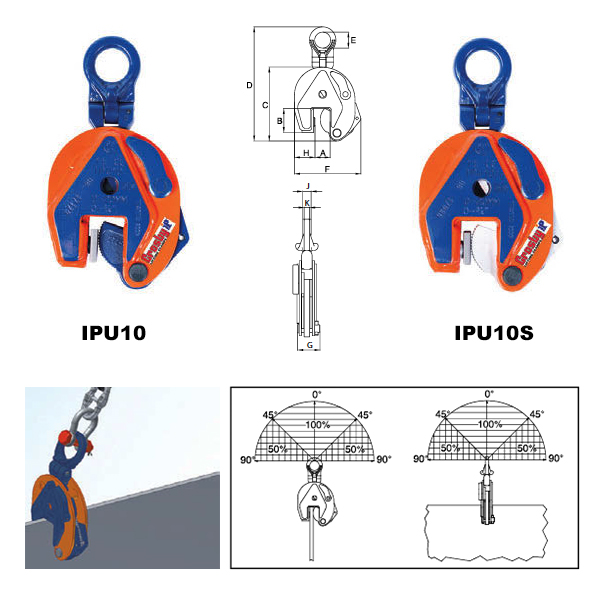

- Available in a variety of styles: – IPU10 – Standard clamp for materials with a surface hardness to 37Rc (345HB).

– IPU10J – Larger jaw opening.

– IPU10S – For use with Stainless Steel material.

– IPU10H – For use with materials with a surface hardness to 47Rc (450HB). - Full 180° turning range for material transfer, turning or moving.

- Lock open, lock closed ability with latch for pretension on material and then release of material.

- Optional IP-5000 Stinger assembly available (see page 420). Allows for easy connection between the clamp and hoist hook.

- Minimum WLL of 10% of Maximum WLL.

- Maintenance replacement kits are available.

- Manufactured by a ISO 9001 facility.

- All sizes are RFID EQUIPPED.

* Design Factor based on EN 13155 and ASME B30.20.

Call Mazzella for your clamp repair or inspection needs!

All brands and capacities … including, but not limited to Renfroe, The Crosby Group, Campbell, CM, SuperClamp, and Terrier. Contact your local Lifting Specialist to arrange for pick-up of your lifting clamps for inspection and/or repair!