Description

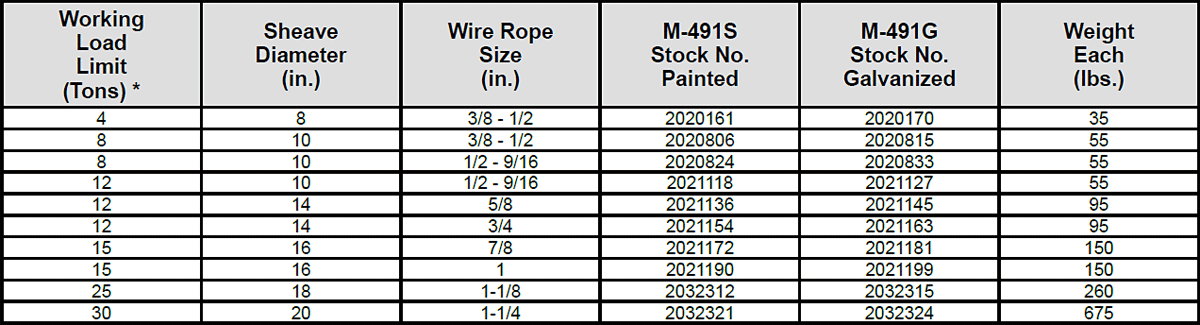

* Ultimate Load is 4 times the Working Load Limit.

New design provides the dependability of standard McKissick® Snatch Blocks, along with features that make it perfect for the challenging needs of Tugger Hoist and Tower Erection applications.

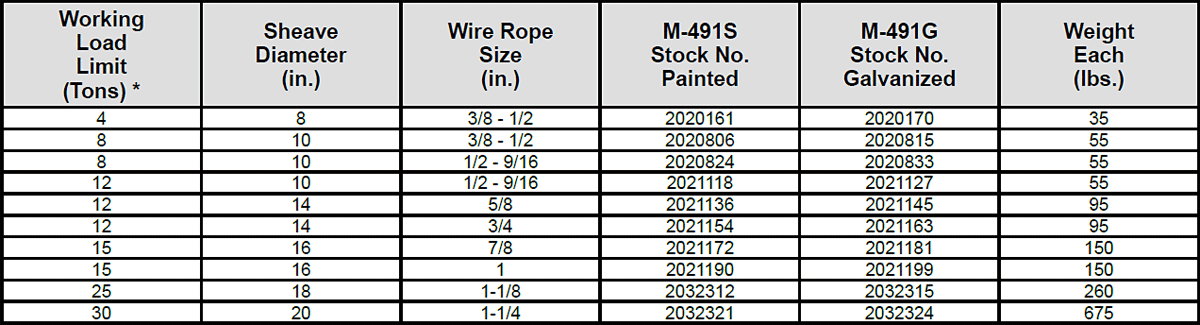

* Ultimate Load is 4 times the Working Load Limit.

Connect with our specialist today! We will help you answer any questions you may have and assist you in completing your project.