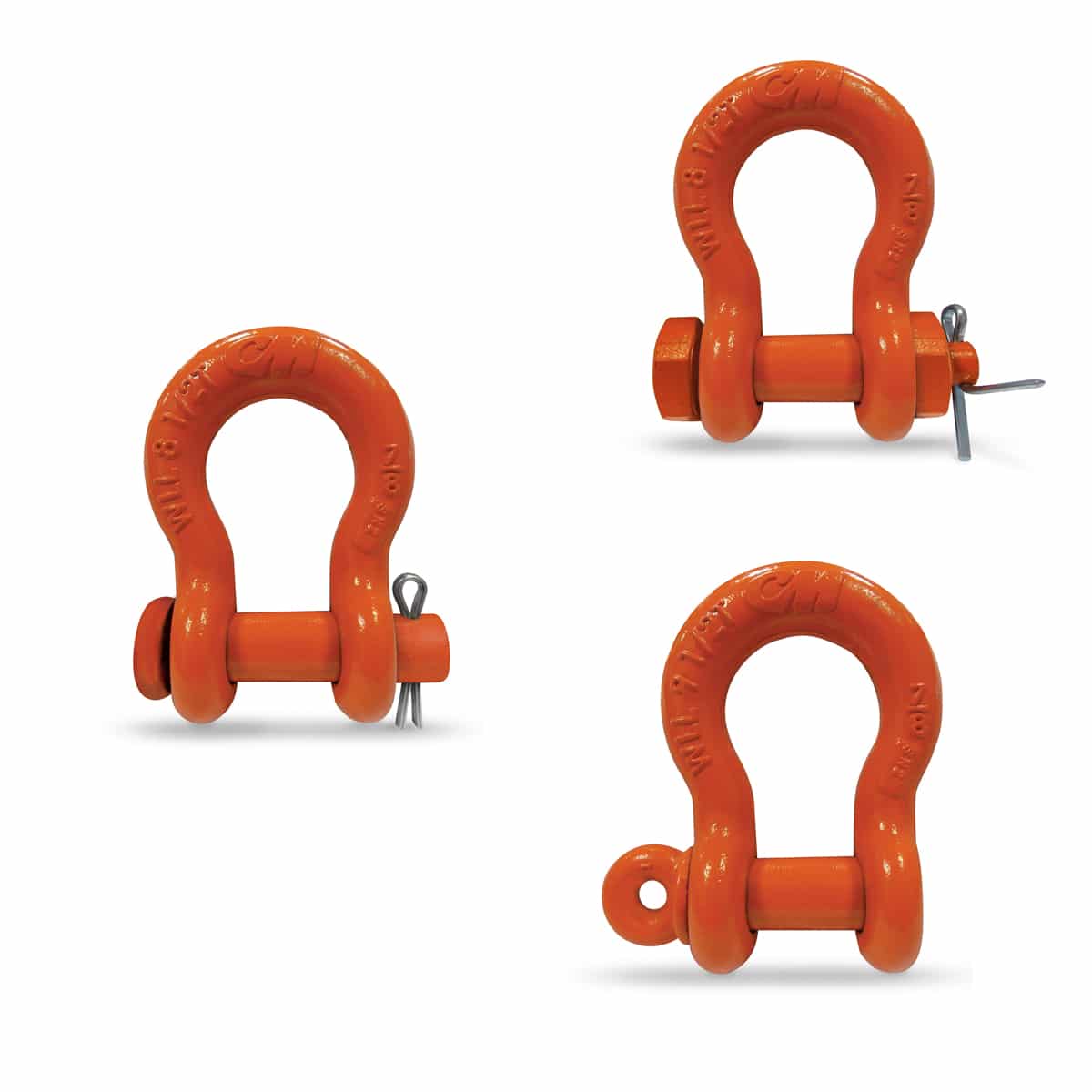

Description

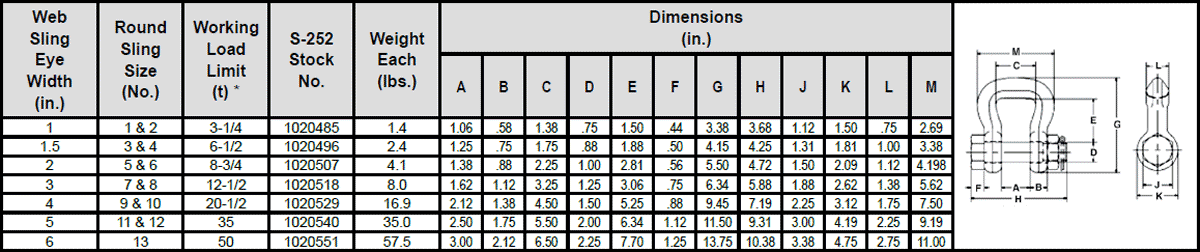

S-252 Bolt Type Sling Shackle

* Maximum Proof Load is 2.5 times the Working Load Limit. Minimum Ultimate strength is 5 times the Working Load Limit.

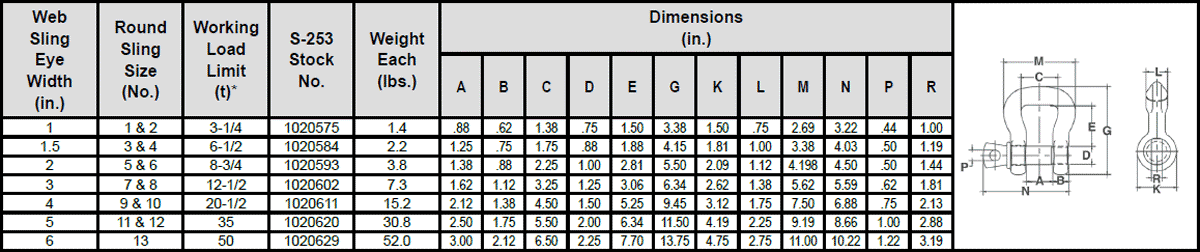

S-253 Screw Pin Sling Shackle

* Maximum Proof Load is 2.5 times the Working Load Limit. Minimum Ultimate strength is 5 times the Working Load Limit.

Crosby Sling Saver hardware meets the requirements for minimum stock diameter or thickness, and effective contact width shown in the Recommended Standards Specification for Synthetic Polyester Round Slings by the Web Sling & Tie Down Association. WSTDA-RS1 (revised 2010).