Description

Technical Features:

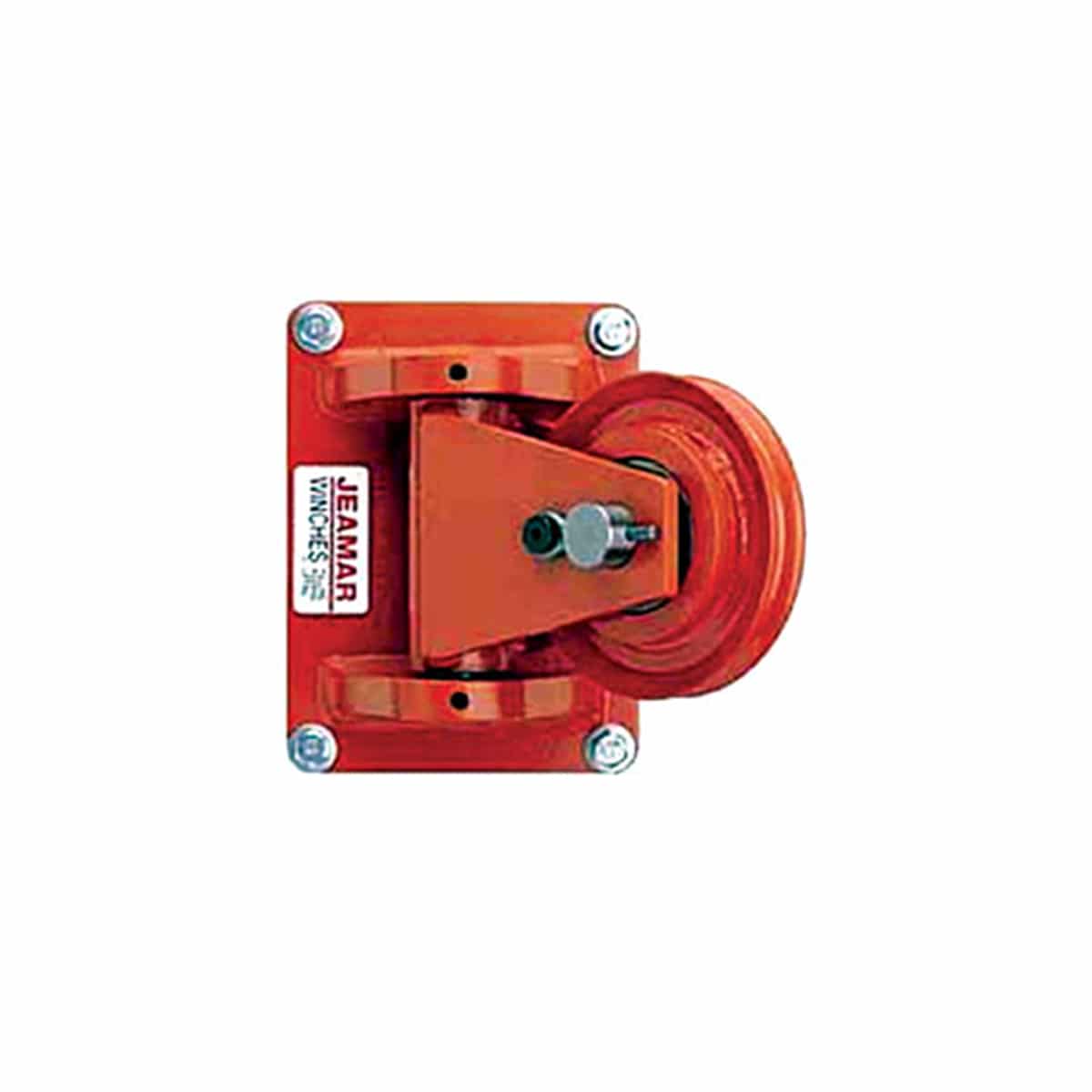

- Quick-reeving configuration with drop-away sheave guards allows easy passage of rope with end fitting in place. Dead end centered above the sheaves on 1-4 sheave blocks, 5 and up dead end to side plate.

- Hooks are forged alloy steel, single or duplex, in accordance with DIN15401 or DIN15402. Single hook blocks include heavy-duty locking latches. Locking latches optional for duplex hooks. All hooks are individually certified for mechanical and physical properties including Charpy impact test, and include ultrasonic and magnetic particle evaluation.

- Design Factor 4 to 1 minimum.

- Bearings for sheaves are low-friction, double-row, full complement cylindrical roller type for tight sheave alignment and high resistance to axial forces caused by variation in fleet angles, and require no friction spacers between sheaves. Hook bearings are tapered roller thrust type as used in all Miller Hi-Lift blocks.

- Lubrication for sheave bearings is not required except under special circumstances. Lubrication via channels in the sheave pin is available. Hook bearing grease fitting is located in the hook upper end.

- Hook-locking device is available for all models over 40 tons. Allows user to lock hook every 90°.

- Side plates and cheek weights are full-length and provided for a range of overhaul weights.