Description

Features & Benefits:

Safety—

- Helps prevent sling cutting that can cause property damage, personal injury and/or death.

Saves Money—

- Protects both sling and load from damage, and increases sling life.

Inspection Criteria for Sling Wear Pads

If pad is damaged, the sling may also be damaged. Inspect both thoroughly and check slings for:

Wire Rope Slings—

- Broken wires

- Kinking

- Abrasive wear

Chain Slings—

- Abrasive wear

- Nicks, cracks

- Gouges, stretch

Web Slings—

- Visible red core warning yarns

- Cuts on the face or edge of webbing

- Holes, tears, snags or crushed web

- Signs of excessive abrasive wear

- Broken or worn threads in the stitch patterns

Operating Practices

Prior to making a lift, the load should be raised slightly, then lowered so that the wear pads can be inspected for damage. If pads show evidence of cutting, the lift should be tested again using a different type / style of wear pad.

Damage to synthetic slings from abrasion or cutting can be prevented if proper protection is provided on the job site. Common materials used to protect the sling from abrasion damage do not provide adequate protection from cutting. If a sling is exposed to an edge under pressure, cutting may occur unless a proven method of protection is provided.

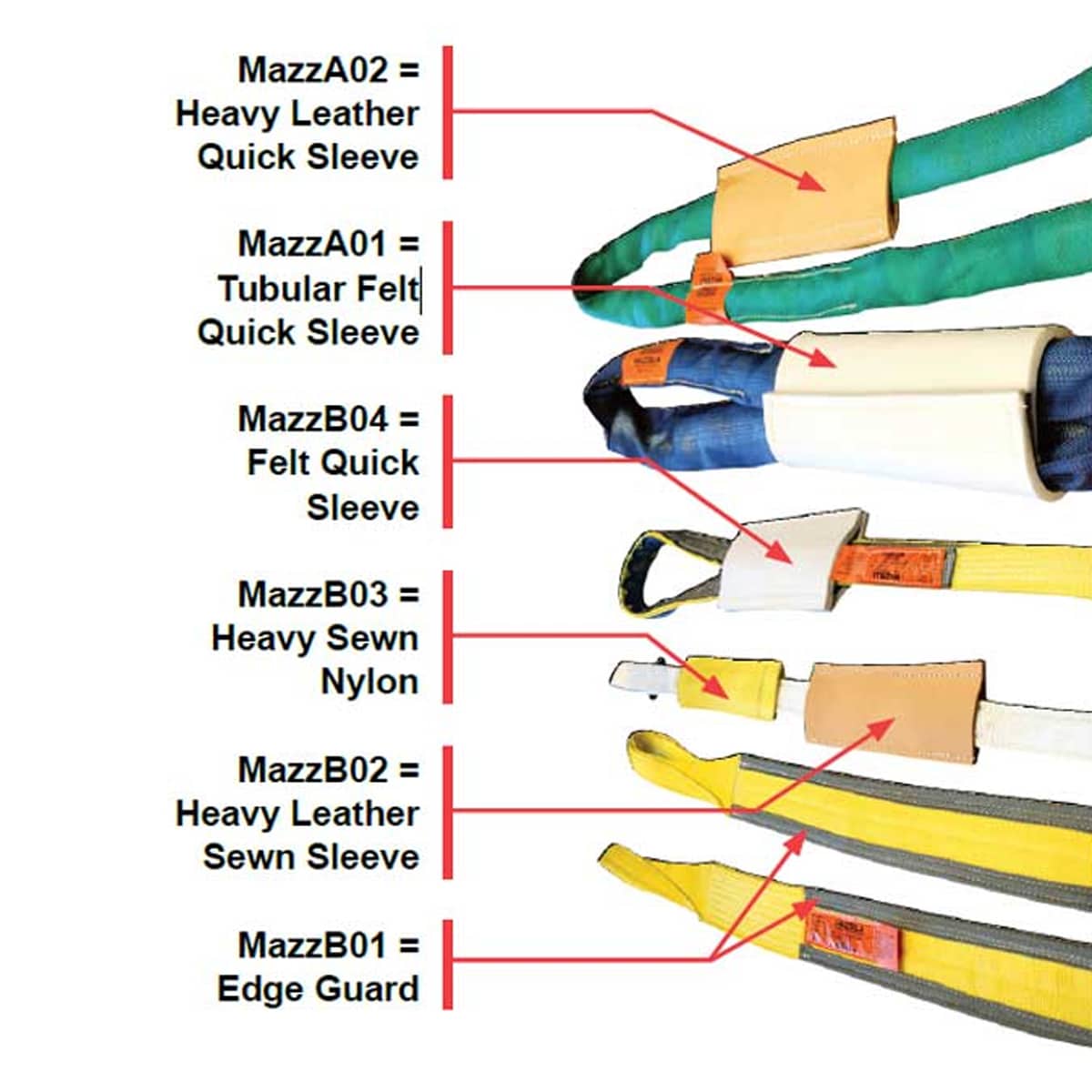

Note: Other materials are available for use as wear pads. Contact our Lifting Specialists for your requirements.

Ask us about CornerMax® pads and CornerMax® sleeves for protection against potential cutting.