Description

Patented Back-up Protection

Twin-Path® Extra and Twin-Path® Extra Covermax slings are actually two complete and separate slings in one. Each path makes its own separate connection between the hook and the load. We do not recommend the use of damaged slings, but chances are good that if damage to one of the paths went undetected that, unlike web slings or other roundslings, you would have sufficient reaction time to maintain control of the load. Only Twin-Path® Extra and Twin-Path® Extra Covermax provide this security.

Ease of Inspection

The Twin-Path® Extra and Twin-Path® Extra Covermax provide an early warning and inspection mechanism. The load carrying yarns never come into contact with the load. There is no wear to them as long as the protective outer covers remain intact. Twin-Path® and Twin-Path® Covermax slings have two independent covers that are color coded for easy inspection.

When the outer cover is cut, the red inner cover instantly becomes visible, providing the sling user with a visual alert to remove the sling from service and send it to the manufacturer for inspection and repair. Damage which exposes the inner load bearing yarns is one criteria for immediate removal from service for inspection and repair. Only Twin-Path® and Twin-Path® Covermax assure such a warning system.

Super Strong—Ultra Light

The Twin-Path® Extra and Twin-Path® Extra Covermax are manufactured with K-Spec® core yarn—an incredible material that is many times stronger than steel at a fraction of the weight. Twin-Path® Extra and Twin-Path® Extra Covermax are ideal for helicopter and aerospace applications.

Check-Fast® Inspection System

The Check-Fast® Inspection System is designed to improve job site safety. The Check-Fast® External Warning Indicator (EWI) provides a criteria for pass/fail inspection when the internal load-bearing core yarn may be damaged. The Check-Fast® Inspection System can also indicates ultraviolet (UV) light degradation, fiber-on-fiber abrasion, fatigue, and severe overload. If the sling is overloaded beyond its rated capacity, the EWI is designed to retract before the sling fails. The sling inspector now has an objective “GO/NO-GO” inspection device rather than relying on subjective and labor-intensive inspection techniques to guess if the load-bearing core yarns are in good condition.

Rifled Cover® Technology

Rifled Cover® Technology is a major patented breakthrough only available on Slingmax® Twin-Path® high-performance fiber roundslings. Rifled Cover® Technology works like the inside of a rifle barrel, where the bullet spins as it leaves the muzzle of the gun. The helical winding of the core fibers significantly improves strength and efficiency.

Twin-Path® high-performance roundslings with patented Rifled Cover® Technology yield three major advantages:

- Increased strength-to-weight ratio. 17% increased breaking strength with the same amount of core yarn.

- Consistent and predictable breaking strength for every sling.

- Repeatability in the manufacturing process.

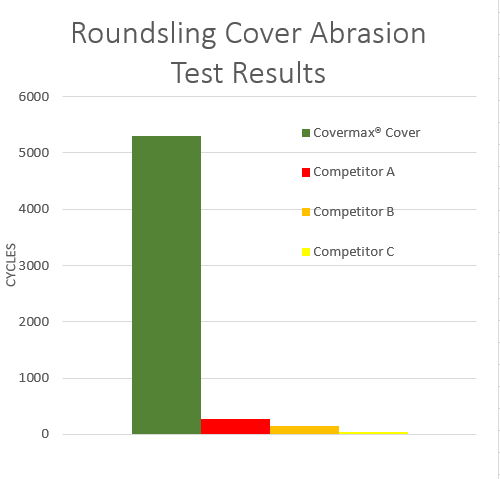

Twin-Path® roundslings are made with the Slingmax® Covermax® Cover. The Covermax® Cover is made with a heavy-duty, double-layer industrial nylon material. The outside cover is green and the inside cover is red. If damage on the green cover allows red to show through, return the sling for factory inspection and repair. This cover has been tested to provide the best ultraviolet (UV) protection and the best abrasion protection on any commercially-available synthetic lifting sling.

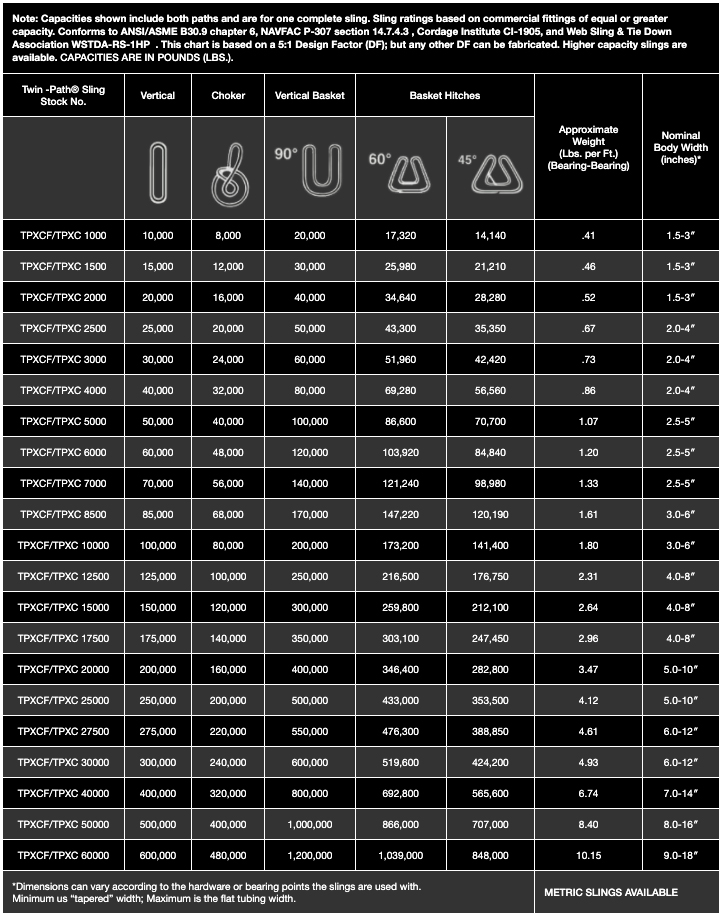

The table below is a sample representation of Twin-Path® slings at a 5:1 Design Factor (DF)/ Safety Factor (SF).

Capacities up to 4000 Te MBL and other DF/SF Twin-Path® products are available. Please call, email, or utilize our “Contact Us” form for special requests.