How to Set Up EPLS on a Magnetek Drive

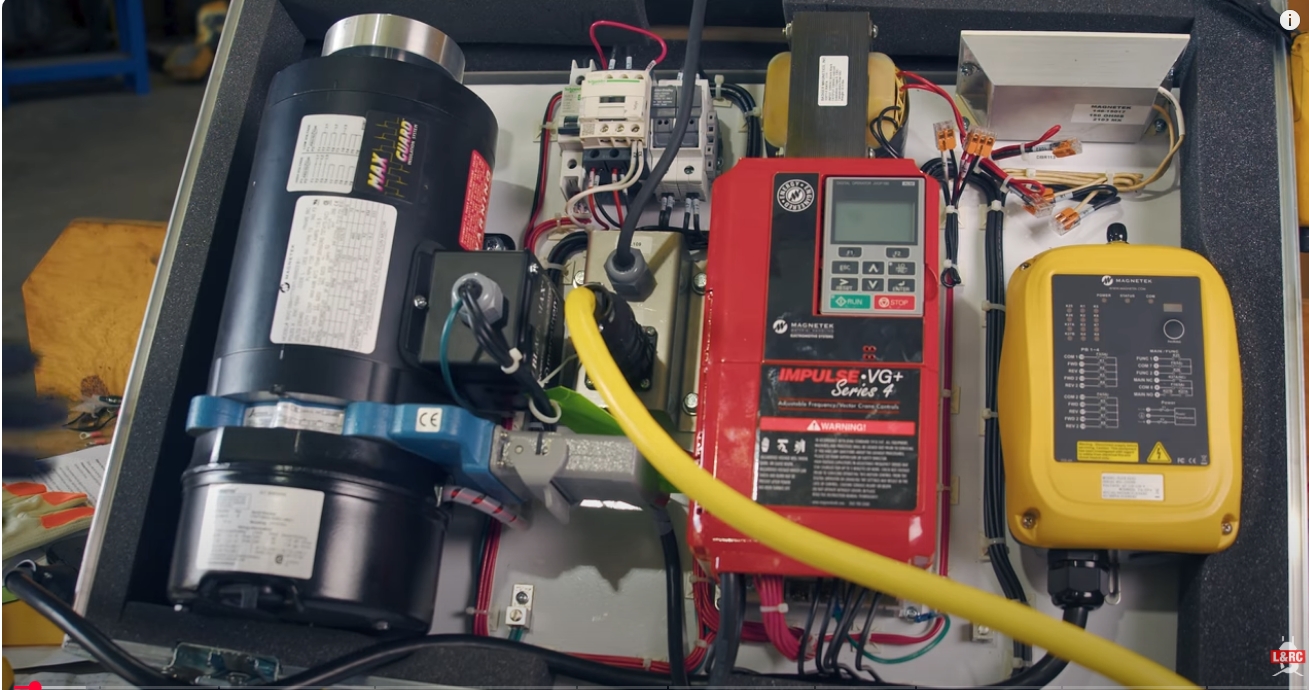

This technical walkthrough shows you how to set up EPLS on a Magnetek IMPULSE Series 4 drive.

For a visual walk through, watch the tutorial video on the Lifting & Rigging Channel:

Whether you’re dealing with failed limit switches, retrofitting an older crane, or need more precise hoist control using encoder feedback, this technical walkthrough shows you how to set up EPLS on a Magnetek IMPULSE Series 4 drive.

What You’ll Need

Ensure your setup includes:

- IMPULSE Series 4 Drive

- Avtron Encoder

- Black Max Motor

- Stearns Brake

- Flex EX2 Receiver

Make sure to also wear the proper personal protective equipment (ppe).

1. Set the Home Position Using Encoder Feedback

A. Wire and Assign Push Button:

- Wire a normally open push button to terminal S5.

- Go to parameter H01-05 and set it to 67 (Hook Height Home).

B. Define Home Position:

- Access C03-14.

- Set it to Home MFDI 2 Upper (your zero point for revolutions).

C. Confirm Zero Position:

- After pressing the button, verify encoder reset via U01-51. It should display 0 revolutions.

2. Set Upper Hoist Travel Limits

A. Navigate to Parameters:

- C03-16: Set UL2 (slowdown) – e.g., 5 revs

- C03-17: Set UL1 (stop) – e.g., 55 revs

B. Clear EPLS Fault:

Run the hoist down until alarms clear due to being outside UL2.

C. Test Upper Limits:

- Run hoist up to confirm slow and stop triggers function at UL1 and UL2.

3. Set Lower Hoist Travel Limits

A. Enter Lower Limits:

- C03-18: Set LL1 (slowdown) – e.g., 200 revs

- C03-19: Set LL2 (stop) – e.g., 250 revs

B. Test Lower Limits:

- Run hoist down and confirm alarms and stop at LL1 and LL2.

4. Fine-Tune as Needed

Once the main limits are functional, you can adjust ramp speeds and distances to better suit your application.

Why Is Setting Up EPLS and Hook Height Management Important?

While it may seem challenging, the benefits of setting up Electronic programmable limit switches and hook height management are worth it:

Precision

Setting up an EPLS allows you to have exact control over a hoist’s movement, allowing for more precise and safe lifts.

Improved Safety

Electronic programmable limit switches serve as a viable backup if the mechanical limits fail.

Convenience

EPLS and hook height measurement allows you to adjust faster and easier, reducing unnecessary downtime and improving productivity in the long run.

Final Thoughts

Relying on just mechanical switches leaves you vulnerable to excessive downtime and less precise lifts. Pairing your mechanical switches with an EPLS system will give you a hoist that is smarter, easier to manage, and better equipped for common in-field challenges.

Here is a brief summary:

Setting up EPLS involves four main steps: setting the home position with encoder feedback, programming upper and lower travel limits using drive parameters, and testing functionality. Once complete, adjust performance settings as needed.

Copyright 2025. Mazzella Companies.