Polyester and Nylon Synthetic Web Slings: Features and Characteristics

When choosing a material for sling use, we recommend considering a material’s resistance to specific chemicals, temperature resistance and stretch.

This article addresses several topics related to nylon and polyester synthetic slings. These features and characteristics are meant as a starting point to help you identify the right type of synthetic sling for your application and are not universally applicable.

Please consult a Lifting Specialist if you have any specific questions regarding the use of synthetic slings with your lifting application.

Use the outline to skip to specific topics:

- What is a Synthetic Web Sling?

- Synthetic Materials

- Nylon

- Polyester

- Basic Sling Types

- Definitions of Terms

- Coatings

- Design Factor

- Web Sling Identification

- Recommended Operating Practices and Mechanical Considerations

- Environmental Considerations

- Acids

- Alkalis

- Degradation Considerations

- Types of Inspection

- Initial Inspection

- Frequent Inspection

- Periodic Inspection

- Removal from Service

- Inspection Records

- Repair of Web Slings

- Effect of Angle

- Red Core Yarns Inspection Aid

What is a Synthetic Web Sling?

A synthetic web sling is synthetic webbing fabricated into a configuration with or without fittings for raising, lowering or suspending applications in general industrial and specialized operations.

Synthetic Materials

When ordering a synthetic sling from Mazzella, one must consider the various characteristics of synthetic slings and their applications. Synthetic slings are made of nylon or polyester webbing in order to suit various applications. When choosing a material for sling use, we recommend considering a material’s resistance to specific chemicals, temperature resistance and stretch.

Nylon

Nylon is the most widely used general purpose synthetic web sling. Nylon is unaffected by grease and oil, and the material has excellent chemical resistance to aldehydes, ethers and strong alkalies. However, nylon slings are not suitable for use with acids and bleaching agents, or at temperatures in excess of 194°F. The stretch of a nylon sling at capacity is approximately 8 to 10%.

Polyester

Polyester web slings are used primarily in conditions where acid is present and minimum stretch is desired. Polyester is unaffected by common acids and bleaching agents, but the material is unsuitable for use in conditions where concentrated sulfuric acid and alkaline is present.

Polyester is also unsuitable in locations where temperatures exceed 194°F. Stretch of a polyester web sling at rated capacity is approximately 3%.

Basic Sling Types

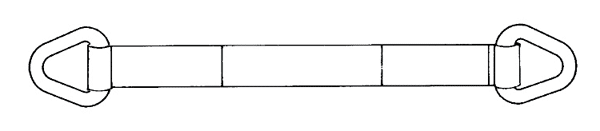

Type I—Web sling made with a triangle fitting on one end and a slotted triangle choker fitting on the other end. It can be used in a vertical, basket or choker hitch.

Type II—Web sling made with a triangle fitting on both ends. It can be used in a vertical or basket hitch only.

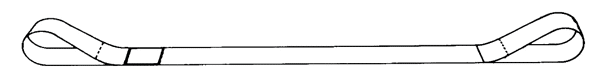

Type III—Web sling made with a flat loop eye on each end with loop eye opening on same plane as sling body. This type of sling is sometimes called a flat eye and eye, eye and eye or double eye sling.

Type IV—Web sling made with both loop eyes formed as in Type III, except that the loop eyes are turned to form a loop eye which is at a right angle to the plane of the sling body. This type of sling is commonly referred to as a twisted eye sling.

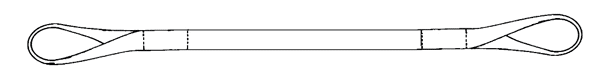

Type V—Endless web sling, sometimes referred to as a grommet. It is a continuous loop formed by joining the ends of the webbing together with a load-bearing splice.

Type VI—Return eye (reversed eye) web sling is formed by using multiple widths of webbing held edge to edge. A wear pad is attached on one or both sides of the web sling body and on one or both sides of the loop eyes to form a loop eye at each end, which is at a right angle to the plane of the web sling body.

Definitions of Terms

Abrasion—The mechanical wearing of a surface, resulting from frictional contact with other materials.

Body—That part of a web sling which is between the end fittings or loop eyes.

Breaking Strength—That load in pounds or kilograms atwhich point any load-bearing part of the sling fails.

Coating—A finish applied for a special purpose.

Design Factor—The ratio of the minimum breaking strength to the “rated capacity” for each new web sling.

Elongation—The measurement of stretch, at a given load, expressed as a percentage of the original unloaded length.

Fabrication Efficiency—The ratio of a web sling assembly strength to webbing strength prior to fabrication, expressed as a percentage.

Fitting—A load-bearing device which is attached to the web sling.

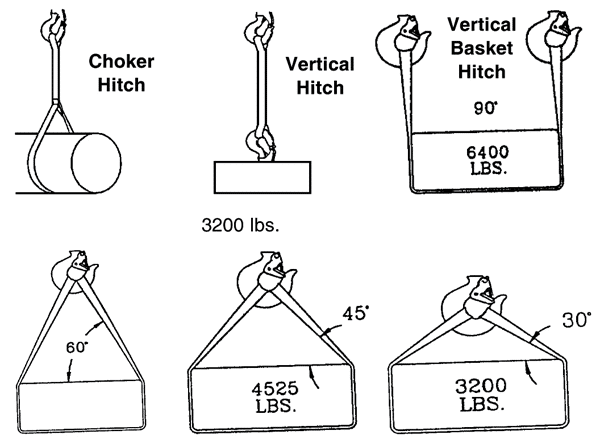

Hitch / Vertical—A method of rigging a web sling in which the load is attached to one end of the web sling and the other end of the web sling is attached to the lifting device.

Hitch / Choker—A method of rigging a web sling in which the web sling is passed around the load, then through itself, then attached to the lifting device.

Hitch / Basket—A method of rigging a web sling in which the web sling is passed around the load, and both ends are attached to the lifting device.

Length (Reach)—The distance between the extreme and bearing points of the web sling, including fittings if applicable.

Loop Eye—A length of webbing which has been folded back upon itself, forming an opening, and joined to the web sling body to form a bearing surface.

Minimum Breaking Strength—Minimum load at which a new web sling or component will break when loaded to destruction in direct tension.

Plies—The number of thicknesses of load-bearing webbing used in the web sling assembly.

Proof Load Test—A non-destructive load test of the web sling to some multiple of the rated capacity of that web sling, including fittings if applicable. (Usually two (2) times the rated capacity.)

Rated Capacity (Working Load Limit)—The maximum allowable load for each web sling assembly for the type of hitch used.

Splice—That part of a web sling which is lapped and secured to become an integral part of the web sling.

Types of splices are as follows:

(a) Load Bearing Splice—Any splice that carries a portion of the total load applied.

(b) Assembly Splice—Any splice that joins two or more parts of the sling without bearing any of the applied load.

Stitch Pattern Failure (Lap pulled apart)—Separation of the load-bearing splice due to thread.

Synthetic Fiber—Man-made fibers.

Synthetic Web Sling—A lifting assembly made of synthetic webbing which is to be used to connect the load to the lifting device.

Tapered Eye—A loop eye which is formed by folding the webbing to a narrower width at its bearing point to accommodate the lifting device. A tapered eye may be either flat (Type III) or twisted (Type IV).

Thickness—The depth of the sling, as opposed to the width or length.

Thread—The synthetic yarn which is used to sew the web sling together.

Triangle Fitting—An end attachment which is used for connecting the web sling to the lifting device.

Triangle Choker Fitting—Similar to the “triangle fitting” except that it also has a slot through which the “triangle fitting” can be passed through in order to permit a “choker hitch” on the load.

Wear Pad—Leather, webbing or other fixed or sliding material used to protect the web sling from being damaged.

Webbing—A fabric woven of high tenacity synthetic yarns offering suitable characteristics for use in the manufacturing of web slings.

Webbing Strength Rating—The minimum strength of webbing, expressed in pounds per inch (or kilograms per centimeter) of webbing width.

Width—The distance across the web sling body from outer selvedge to outer selvedge.

Working Load Limit—See rated capacity.

Yarn—The synthetic fibers used to make the webbing and thread.

Coatings

Web slings may be coated with suitable materials that will impart desirable characteristics, such as:

- Abrasion resistance

- Sealing to prevent penetration of foreign particles and matter

- Increased coefficient of friction

Design Factor

The design factor for new synthetic web slings with or without fittings shall be a minimum of 5:1.

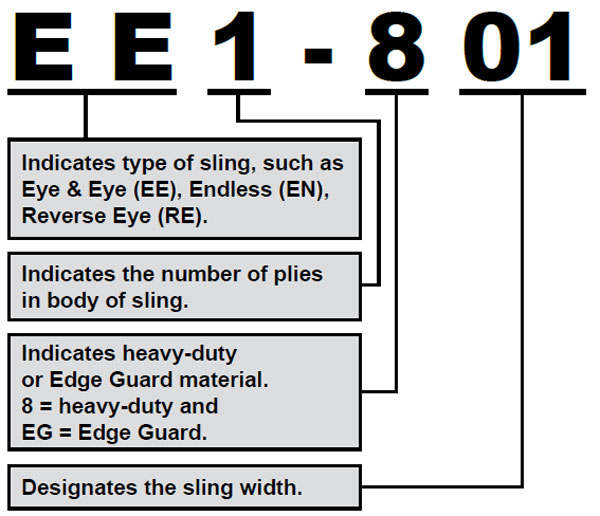

Web Sling Identification

Each web sling shall have a permanently affixed identification tag marked to show:

- Name or trademark of manufacturer

- Manufacturer’s code or stock number

- Rated capacities for at least one hitch type and the angle upon which it is based

- Type of synthetic web yarn

- Number of legs if more than one

*We place a unique identifier / serial number on all the slings we manufacture.

Recommended Operating Practices and Mechanical Considerations

Determine weight of the load. The weight of the load shall be within the rated capacity of the web sling.

Select a web sling having suitable characteristics for the type of load, hitch and environment.

Web slings shall not be loaded in excess of the rated capacity.

Consideration shall be given to the sling to load angle, which affects rated capacity.

Web slings with fittings, which are used in a choker hitch, shall be of sufficient length to ensure that the choking action is on the webbing and never on the fitting.

Web slings used in a basket hitch shall have the load balanced to prevent slippage.

The opening in fittings shall be the proper shape and size to ensure that the fitting will seat properly in the hook or other attachments. Web slings shall always be protected from being cut by corners, edges, protrusions or abrasive surfaces. Web slings shall not be dragged on the floor or over abrasive surfaces.

Web slings shall not be twisted, shortened, lengthened, tied in knots or joined by knotting. Web slings shall not be pulled from under loads when the load is resting on the web sling. Do not drop web slings equipped with metalfittings. Web slings that appear to be damaged shall not be used unless inspected and accepted as usable.

The web sling shall be hitched in a manner providing control of the load. Personnel, including portions of the human body, shall be kept from between the sling and the load, and from between the sling and the crane hook or hoist hook. Personnel shall stand clear of suspended loads.

Personnel shall not ride the web sling or the load being lifted. Shock loading shall be avoided.

Twisting and kinking the legs (branches) shall be avoided. Load applied to the hook shall be centered in the base (bowl) of hook to prevent point loading on the hook.

During lifting, with or without the load, personnel shall be alert for possible snagging.

The web sling’s legs (branches) shall contain or support the load from the sides above the center of gravity when using a basket hitch. Web slings shall be long enough so that the rated load (rated capacity) is adequate when the sling to load angle is taken into consideration. Only web slings with legible identification tags shall be used. Tags and labels should be kept away from the load, hook and point of choke. Web slings shall not be constricted or bunched between the ears of a clevis, shackle or in a hook.

Place blocks under load prior to setting down the load to allow removal of the web sling, if applicable.

Environmental Considerations

- Slings should be stored in a cool, dry and dark place, and should not be exposed to ultra-violet light (sunlight).

- Chemically active environments can affect the strength of synthetic web slings in varying degrees ranging from none to total degradation. The sling manufacturer should be consulted before using slings in chemically active environments.

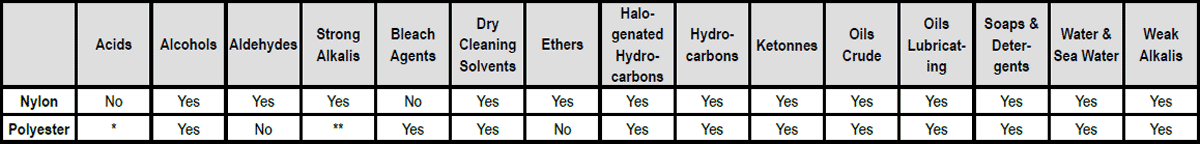

- Acids:

(a) Nylon is subject to degradation in acids, ranging from none to total degradation.

(b) Polyester is resistant to many acids, but is subject to degradation ranging from none to moderate in some acids. - Alkalis:

(a) Polyester is subject to degradation in alkalis,ranging from none to total degradation.

(b) Nylon is resistant to many alkalis, but is subject to degradation ranging from none to moderate insome alkalis- - See chart below for effects of other chemicals on web slings.

- Nylon and polyester slings shall not be used at temperatures in excess of 194°F (90°C); however, they may be used in temperatures as low as -40°F (-40°C).

- Slings incorporating aluminum fittings shall not be used where fumes, vapors, sprays, mists or liquids of alkalis and/or acids are present.

- Environments in which synthetic web slings are continuously exposed to ultra-violet light (sunlight) can affect the strength of synthetic webbing in varying degrees, ranging from slight to total degradation. The degradation is also cumulative.

** Degraded by strong alkalis at elevated temperatures

Acids

Nylon is subject to degradation in acids, ranging from little to total degradation.

Polyester is resistant to many acids, but is subject to degradation, ranging from little to moderate in some acids. Each application shall be evaluated, taking into consideration the following:

(a) Type of Acid

(b) Exposure Conditions

(c) Concentration

(d) Temperature

Alkalis

Polyester is subject to degradation in alkalis, ranging from little to total degradation.

Nylon is resistant to many alkalis, but is subject to degradation ranging from little to moderate in some alkalis. Each application shall be evaluated, taking into consideration the following:

(a) Type of Alkalis

(b) Exposure Conditions

(c) Concentration

(d) Temperature

Degradation Considerations

Factors which affect the degree of strength loss are:

1. Length of time of continuous exposure

2. Web sling construction and design

3. Other environmental factors, such as weather conditions and geographic location

Suggested procedures to minimize the affects of ultra-violet light:

1. Store web slings in a cool, dry, dark place when not being used for prolonged periods of time.

Some visual indications of ultra-violet degradation are:

1. Bleaching out of web sling color

2. Increased stiffness of web sling material

3. Surface abrasion in areas not normally in contact with the load

Proof Testing—Slings used in environments where they are subject to continuous exposure to ultra-violet light shall be proof-tested to twice the rated capacity semi-annually, or more frequently depending on severity of exposure

* Caution: Degradation can take place without visible indications.

Types of Inspection

Initial Inspection

Before any new or repaired web sling is placed in service, it shall be inspected by a designated person to ensure that the correct web sling is being used, as well as to determine that the web sling meets the requirements of this specification.

Frequent Inspection

This inspection shall be conducted by a qualified person handling the sling each time the sling is used.

Periodic Inspection

This inspection shall be conducted by designated personnel. Frequency of inspection should be based on:

- Frequency of web sling use

- Severity of service conditions

- Experience gained on the service life of web slings used in similar applications

- Inspections should be conducted at least annually

Removal from Service

A sling shall be removed from service if any of the following are visible:

- If sling rated capacity or sling material identification is missing or not legible

- Acid or alkalis burns

- Melting, charring or weld spatter on any part of the web sling

- Holes, tears, cuts, snags or embedded particles

- Broken or worn stitching in load bearing splices

- Excessive abrasive wear

- Knots in any part of the web sling

- Distortion and excessive pitting, corrosion or broken fittings

- Any conditions which cause doubt as to the strength of the sling

Inspection Records

Written inspection records, utilizing the identification for each sling as established by the user, should be kept on file for all web slings. These records should show a description of the new web sling and its condition on each subsequent inspection.

Repair of Web Slings

Sling webbing with structural damage shall never be repaired. Type I and Type II web slings, and other web slings utilizing hardware, may be re-webbed utilizing existing fittings. It shall be the responsibility of the manufacturer repairing the web sling to determine if the hardware is re-usable.

All re-webbed Type I and Type II, and other web slings utilizing fittings, shall be proof-tested to two (2) times their vertical rated capacity before being placed back into service. A certificate of proof-testing shall be provided. Temporary repairs of webbing, fittings or stitching shall not be permitted.

Effect of Angle

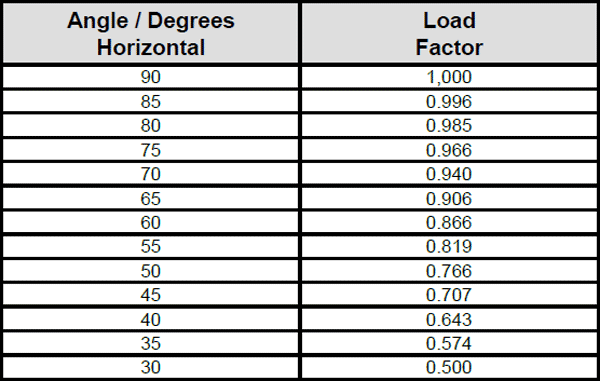

Rated capacities are affected by the angle of lift (sling to load). When multi-legged slings are used, the sling angle created must be taken into consideration in order to determine the actual rated capacity of the bridle or multi-legged sling. The rated lifting capacity is reduced depending on this angle. At 90 degrees measured from the horizontal, the rated capacity is 100%, but as the angle decreases, so does the rated capacity. The amount of capacity reduction is displayed by the chart to the right.

To calculate the rated capacity on a multi-legged lifting sling, proceed as follows:

- Multiply the vertical capacity of the single sling leg by the number of sling legs to be utilized. For example, if the vertical capacity of the single leg is 3200 lbs. and a two-legged lifting sling is to be used, then the combined vertical capacity of the two legs is 6,400 lbs.

- Determine the angle of lift measured from the horizontal.

- Find the appropriate load factor from the chart at the right based on the angle of lift determined.

- Multiply the combined rated capacity of 6,400 lbs. by the load factor. For example, if the angle of lift is 60 degrees, then multiply 6,400 by .866. 6,400 x .866 = 5,542. Therefore, the rated capacity of this 2-legged sling at 60 degrees is 5,542 lbs.

Red Core Yarns Inspection Aid

All standard Mazzella nylon and polyester web slings have red warning yarns. Red core yarns may become exposed when the sling surface is cut or worn through the woven face yarns. This is one criteria, but not the only one for removal from service!

Portions of this page reprinted from Synthetic Web Slings—Web Sling & Tie Down Association

CAUTION: These tips are provided as a starting point in the selection process and are not universally applicable. Please consult our experts for the solution to your specific application.