ASME B30.16-2022: Updates & Revisions to the ASME B30.16 Standard

ASME B30.16 Overhead Underhung and Stationary Hoists helps set the standards for the lifting and rigging industry. It outlines maintenance, training, safe use, and inspection criteria for multiple types of hoists.

The American Society of Mechanical Engineers (ASME) is a professional association and leading international developer of codes and standards associated with the art, science, and practice of mechanical engineering. ASME membership is comprised of engineers, scientists, government officials, and others who voluntarily contribute their technical expertise.

ASME standards and safety codes are intended to enhance public safety and offer best practices and applicable regulations within specific industries and jurisdictions. ASME standards are accredited as meeting the criteria of the American National Standards Institute (ANSI).

Every couple of years, the B30 Committee reviews, revises, and amends their existing standards and releases a new edition. The Committee revises the standards based on numerous considerations, including:

- Technological advances

- New Data

- Changing environmental and industry needs

In this article, we’ll discuss the revisions, updates, and additions to the newly released ASME B30.16-2022 Overhead Underhung and Stationary Hoists standard, compared to the previously released 2017 edition.

What is ASME B30.16-2022 Overhead Underhung and Stationary Hoists?

The first ASME B30.16 Overhead Underhung and Stationary Hoists standard was issued in 1998, and since then, has been revised and published by the B30 Committee in 2003, 2007, 2012, and 2017.

The new ASME B30.16 Overhead Underhung and Stationary Hoists standard revises and supersedes the procedures outlined in the 2017 edition of the same standard. According to the standard itself, ASME B30.16-2022 Overhead Underhung and Stationary Hoists includes provisions that apply to the construction, installation, operation, inspection, testing, and maintenance of overhead underhung and stationary hoists, including hand-chain-operated, electric-powered, and air-powered chain and wire rope hoists used for, but not limited to, vertical lifting and lowering of freely suspended, unguided loads that consist of equipment and materials.

What’s New in ASME B30.16-2022 Overhead Underhung and Stationary Hoists?

One of the more notable changes to the ASME B30.16 Overhead Underhung and Stationary Hoists standard is the addition of a definition for an angle of loading.

ASME B30.16 Overhead Underhung and Stationary Hoists defines an angle of loading as: “the angle between a hoist rope or load chain and the vertical axis.”

Previously, there was no listed definition for “angle of loading.” The only mentions of loading in the 2017 standard was definitions for rated load (capacity), working load, and load suspension parts.

Additionally, the definition of “rope” was revised to now read: “refers to wire rope or synthetic rope per ASME B30.30 Ropes.

In the 2017 standard, “rope” was defined as “refers to wire rope unless otherwise specified.”

The references section was revised in its entirety, and a figure (16-0.2-1) as a graphical representation for angle of loading.

Chapter 0: Scope, Definitions, Personnel Competence, and References

Along with the addition of a definition for “angle of loading” and the revision made to the definition for “rope,” the B30 Committee revised the “References” section in its entirety.

Now, the reference section includes the following standards:

- AA ADM-2020 Aluminum Design Manual (Published by Aluminum Association, Inc.)

- ANSI / AISC 360-16, Specification for Structural Steel Buildings (Published by American Institute of Steel Construction)

- ANSI ECMA 15-2018, Specifications for Cable-less Controls for Electric Overhead Traveling Cranes (Published by Monorail Manufacturers Association, Inc.)

- ANSI / NEMA Standards Publication No. ICS 6-1993, Industrial Control and Systems: Enclosures (Published by National Electrical Manufacturers Association [NEMA])

- ANSI Z535.4-2011, Product Safety Signs and Labels (Published by NEMA)

- ANSI / NFPA 70-2020, National Electrical Code (Published by National Fire Protection Association [NFPA])

- ASME B29.24-2002 (R2016) Roller Load Chains for Overhead Hoists*

- ASME B30.9-2018 Slings*

- ASME B30.10-2019 Hooks*

- ASME B30.17-2015 Overhead and Gantry Cranes (Top Running Bridge, Single Girder, Underhung Hoist)*

- ASME B30.20-2018 Below-the-Hook Lifting Devices*

- ASME B30.26-2020 Rigging Hardware*

- ASME B30.30-2019 Ropes*

- ASME HST-1-2017 Performance Standard for Electric Chain Hoists*

- ASME HST-2-2018 Performance Standard for Hand Chain Manually Operated Chain Hoists*

- ASME HST-4-2016 Performance Standard for Overhead Electric Wire Rope Hoists*

- ASME HST-5-2020 Performance Standard for Air Chain Hoists*

- ASME HST-6-2020 Performance Standard for Air Wire Rope Hoists*

- ASSP Z244.1-2016 (R2020) The Control of Hazardous Energy Lockout, Tagout and Alternative Methods (Published by The American Society of Safety Professionals [ASSP])

- ASTM A1023 / A1023M-2021 Standard Specification for Carbon Steel Wire Ropes for General Purposes#

- ASTM E2349-2019 Standard Practice for Safety Requirements in Metal Casting Operations: Sand Preparation, Molding, and Core Making; Melting and Pouring; and Cleaning and Finishing#

- ISO 7000-2012 Graphical symbols for use on equipment – Registered symbols$

- ISO 7296-1991 Cranes – Graphical symbols – Part 1$

*-Published by the American Society of Mechanical Engineers

#-Published by the American Society for Testing and Materials (ASTM International)

$-Published by the International Organization for Standardization (ISO)

References Added

- ANSI / AISC 360-16, Specification for Structural Steel Buildings

- ASME B30.20-2018 Below-the-Hook Lifting Devices

- ASME B30.26-2020 Rigging Hardware

- ASME B30.30-2019 Ropes

References No Longer Used

Most of the references are the same as the 2017 standard, but they had been updated by their respective organizations from older editions. However, several reference materials were not used in the creation of the 2022 standard, including:

- AIS / ASD Manual of Steel Construction

- AISC / LRFD Manual of Steel Construction, 2nd Edition

- ASME B30.11-2010 Monorails and Underhung Cranes

Chapter 1: Marking, Construction, and Installation

Figure 16-0.2-1

This figure provides a graphical representation for “angle of loading.”

Section 16-1.1.5

For this section, the first paragraph and subparagraph (c) were revised, but subparagraph (e) was added and reads:

“The entities responsible for the operation, use, inspection, testing, maintenance, assembly, and disassembly of the hoist shall have the technical and safety-related information available in a language that their employees can read and understand. If the information is not available in a language understood by their employees, the entities shall obtain a translation of the original manufacturer’s technical and safety-related information from the manufacturer or from a translation service provider. The translation(s) shall meet the requirements of (c) and (d).”

Section 16-1.2.1 Mechanical Design

Subparagraphs (b) and (c) about load suspension parts and power transmission were revised.

Section 16-1.2.6 Ropes (Electric- or Air-Powered Hoists Only)

The Ropes (Electric- or Air-Powered Hoists Only) section was revised in its entirety.

Section 16-1.2.14 Overtravel Protection (Electric- or Air-Powered Hoists Only)

The Overtravel Protection (Electric- or Air-Powered Hoists Only) section was revised in its entirety.

Section 16-1.2.17 Manual

Subparagraph (e) was revised, while subparagraphs (f) and (g) were added to the Manual section.

Subparagraphs (f) and (g) read as follows:

(f) Wire Rope Information (wire rope hoists only) may be supplied separately

- Nominal rope diameter

- Rope classification (e.g. 6X19, 6X36, 8X19, 8X36, 19X19, 35X7)

- ASTM A1023 / A1023M rotation resistance Category 1, 2, or 3 (if applicable)

- Rope core (e.g., IWRC, fiber core)

- Lay direction and lay type (e.g., RRL, RLL, LAL, sZ, zZ)

- Minimum breaking force

(g) Synthetic rope information (synthetic rope hoists only) may be supplied separately

- Nominal rope diameter

- Rope construction (e.g. 12-strand single braid, 6-strand cable laid)

- Material type of load-bearing yarns

- Operating temperature range

- Minimum breaking force and test method (e.g., ISO, Cordage Institute)

Section 16-1.3.2 Support

This section was revised, and now reads: “The supporting structure, including trolleys, monorail, or crane, shall be designed to withstand the loads and forces imposed by the hoist for the rated load. The supporting structure should conform to the design parameters as specified in the applicable AISC Specification for Structural Steel Buildings, Aluminum Design Manual, or applicable design manual or standard for the material used.”

Chapter 2: Inspection and Testing

Paragraphs 16-2.1.1 through 16-2.1.5 were revised, while paragraph 16-2.1.7 Inspection Records was deleted.

Table 16-2.1.4-2 was revised from “Inspection of Electric- or Air-Powered Hoists” to “Inspection for Hand-Chain-Operated Hoists.”

Subparagraphs (a)(2)(-d) and (b)(2)(-d) were revised to outline the replacement of load chain for hoists in which load-suspension parts that are altered, replaced, or repaired for hand-chain, electric-powered, or air-powered hoists.

Chapter 3: Operator Training and Operation

Section 16-3.6(b) was revised and now reads “the lockout / tagout policy and procedure shall comply with the requirements of ASSP Z244.1.”

Previously, the reference was cited as ASSE Z244.1.

Chapter 4: Maintenance Training and Maintenance

In Section 16-4.2.4 Responsibilities of Maintenance Persons, subparagraphs (e) and (i) were revised.

Subparagraph (e) now reads: “becoming familiar with load chain and rope replacement criteria.” Previously, this subparagraph specified load chain and wire rope only.

Subparagraph (i) now reads: “not attempting to repair a damaged rope or load chain.” Previously, this subparagraph specified load chain and wire rope only.

Section 16-4.4 Rope Replacement and Maintenance was revised in its entirety.

Breaking Down the ASME B30.16 Overhead Underhung and Stationary Hoists Updates and Revisions

While several parts of the standard were added, others were either updated or revised.

Updates were made to the following sections:

- B30 Standard Introduction

- Section 16-3.6: Equipment Lockout / Tagout Reference

Revisions were made to the following sections:

- Section 16-0.4-References

- Section 16-1.2.1-Mechanical Design

- Section 16.1.2.6-Ropes (Electric- or Air-Powered Hoists Only)

- Section 16-1.2.14-Overtravel Protection (Electric- or Air-Powered Hoists Only)

- Section 16-1.2.17-Manual

- Section 16-1.3.2-Support

- Section 16-2.1-Inspection

- Table 16-2.1.4-2-Inspection of Electric- or Air-Powered Hoists Only

- Section 16-2.2.2-Load Test

- Section 16-3.6-Equipment Lockout / Tagout

- Section 16-4.2.4-Responsibilities of Maintenance Persons

- Section 16-4.4-Rope Replacement and Maintenance

Additions were made to the following sections:

- Figure 16-0.2-1

- Section 16-1.1.5-Subparagraph (e)

- Section 16.1.2.17-Subparagraphs (f) and (g)

Section 16-2.1.1.7 was deleted from the standard.

How Can Mazzella Help You Stay in Compliance with ASME B30.16 Overhead Underhung and Stationary Hoists?

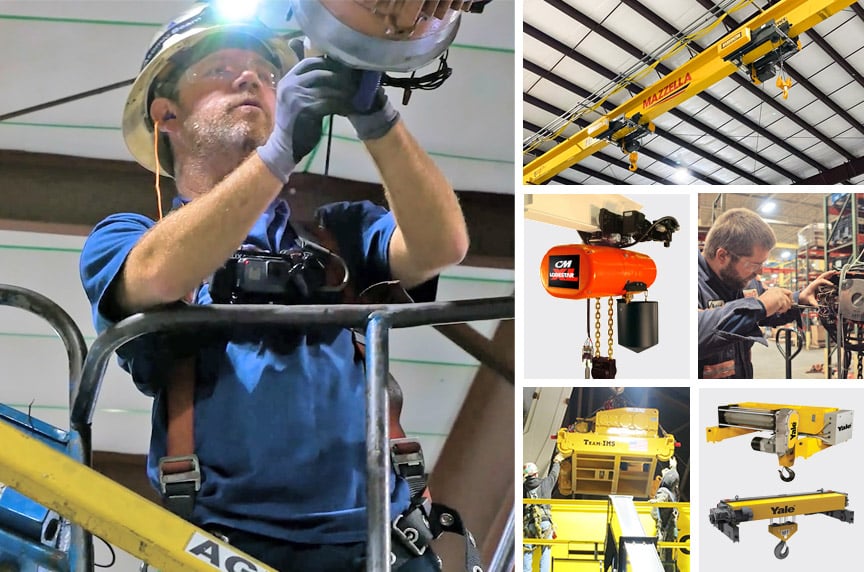

We are your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

Also, we are one of the largest authorized stocking master parts depots for Columbus McKinnon (CM) Companies. We feature Budgit, Coffing, Acco / Wright, Yale, Shaw-Box, and Harrington, and many other manufacturers’ products. Call our Parts Department for your hoist parts needs.

If you are not looking to replace a hoist unit, we also have a Hoist Repair Department available to get your hoist back up and running. We provide in-house repair of electric, lever, manual chain, and wire rope hoists.

We offer the following to our customers seeking hoist repairs and inspections:

- Only the most experienced and qualified technicians are assigned to perform hoist inspections and repairs

- Repairs and testing comply with ASME B30.16 and ASME B30.17 specifications

- Static and dynamic tests are performed

- Test certificates are available electronically or paper will be provided

- Repairs and testing are performed at our facility

- All repaired hoists and pullers are load tested

- We can repair and test to theatrical standards upon request

Call us at 800.362.4601 or click here if you need hoist units or parts!

Hoists, Hoist Parts, & Repair!

We are your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

We are also one of the largest authorized stocking master parts depots for Columbus McKinnon (CM) Companies. We feature Budgit, Coffing, Acco / Wright, Yale, Shaw-Box, and Harrington…just to name a few. Call our Parts Department for your hoist parts needs.

Copyright 2022. Mazzella Companies.