A Breakdown of Scope: Reasons to Consider AI-Enhanced Utility Stringing Line Inspections

Scope is an AI-powered software that identifies damage or defects, and predicts the break strength on utility stringing lines. Our article break down its key functions and benefits.

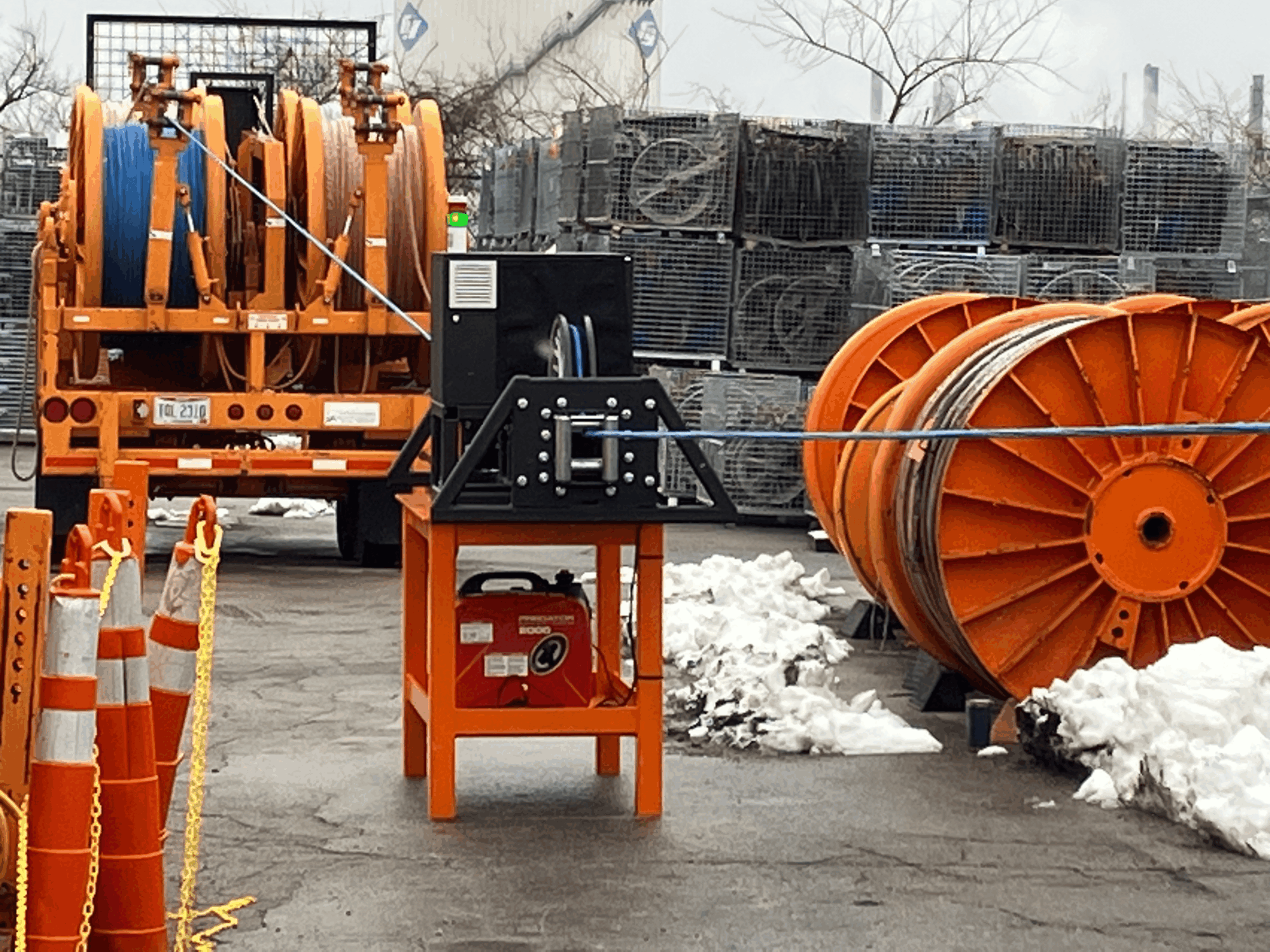

As the US continues to increase electricity grid infrastructure through new builds and upgrades to existing electric power lines, the industry has experienced a significant increase in stringing line operations. The synthetic fiber rope used to pull in new conductor is a critical component for these stringing line operations.

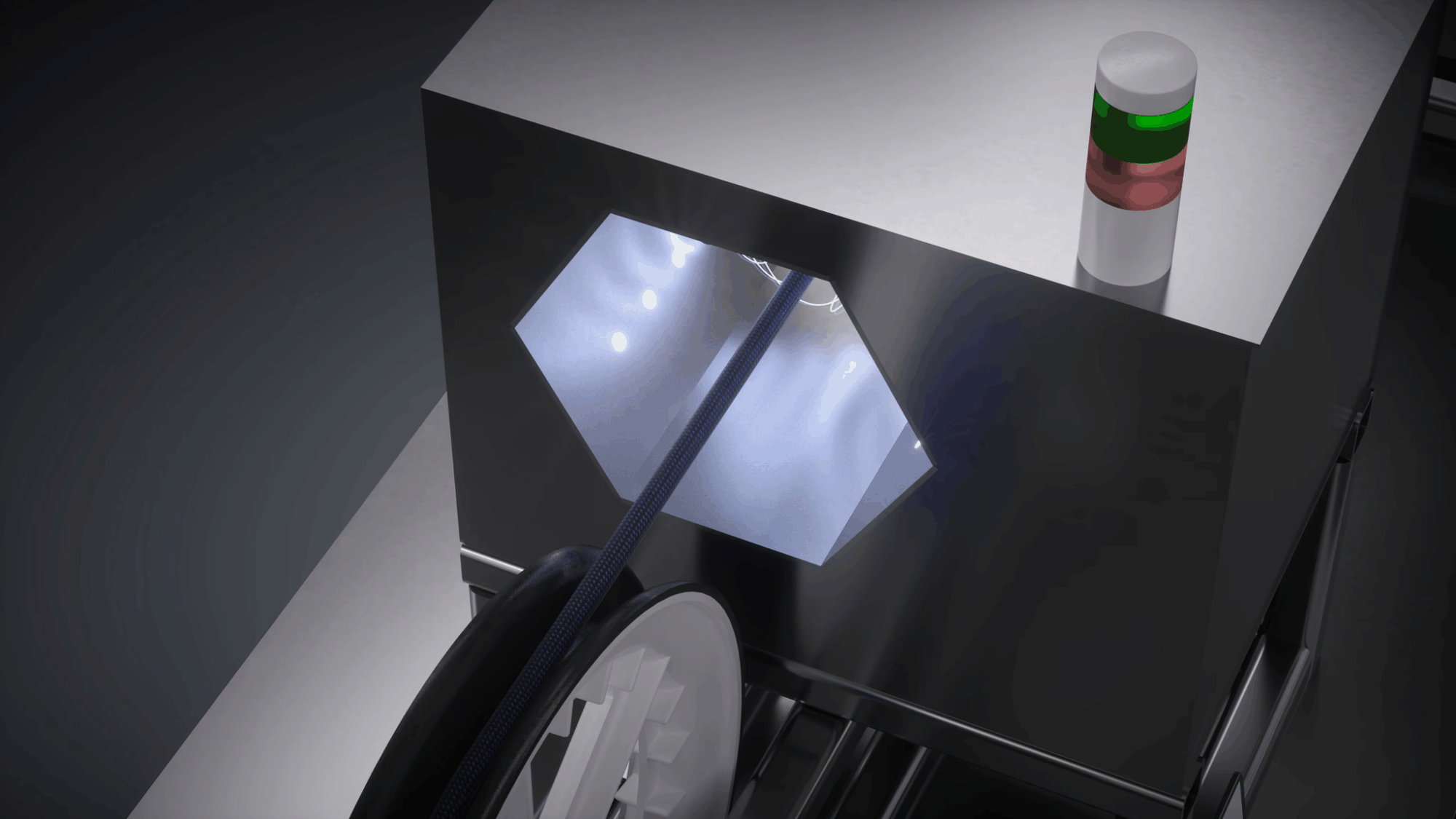

Traditional rope inspections rely on human judgement and guess work, and the human eye can miss critical details that can lead to a catastrophic failure. This is where Scope comes in. Scope is an AI-powered inspection platform that captures a 360° view of the line, predicting break-strength and identifying potential hazards. This occurs in real-time, with software that is continuously learning and improving.

Since launching, major utility companies and contractors have used Scope to improve their inspection processes and create better documentation of their fleet’s stringing lines.

We understand that traditional rope inspections can slow down turnaround times, prolong equipment malfunctions, and open the door for inaccurate stories. With increasing demand for stringing line operations, you have no room for these issues to pop up at your job site.

To help, our article looks to break down everything you need to know about the Scope Inspection Platform, including:

What Is Scope?

Scope is a software and hardware platform that identifies damage or defects, and predicts the break strength of stringing lines, much of which may be overlooked in a manual inspection process.

The average line inspection process is a labor-intensive and time-consuming project. While technicians in the field are knowledgeable—and usually have years of experience—manual processes open the door for human error and inaccuracies, which can lead to serious injuries and prolonged down times.

Many utility companies also don’t consider the damage occurring to their synthetic stringing lines over months of use and exposure to the elements, which only increases the chance of potential failure. Scope is trained to identify common debris, cuts to strands and splices, while correlating visual features of abrasion to a predicted break-strength for that line segment.

Not only can Scope’s technologies assist in line inspections, but it can also be used as a repository to store and document inspection data for the rope’s entire lifespan.

How Do Scope Inspections Work?

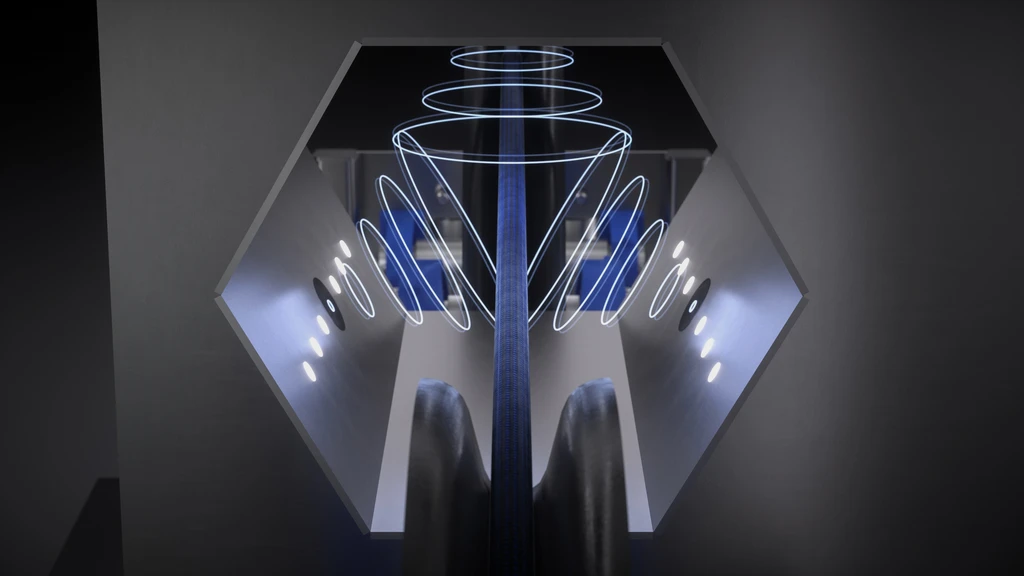

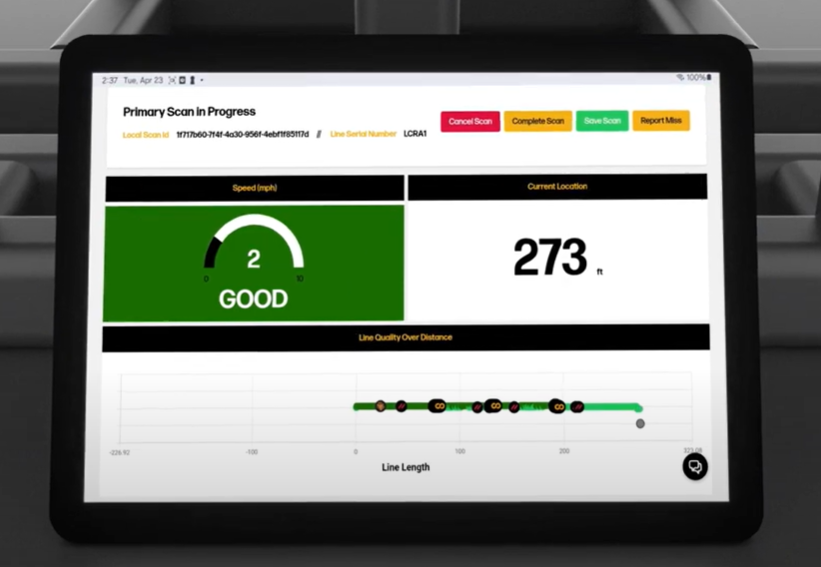

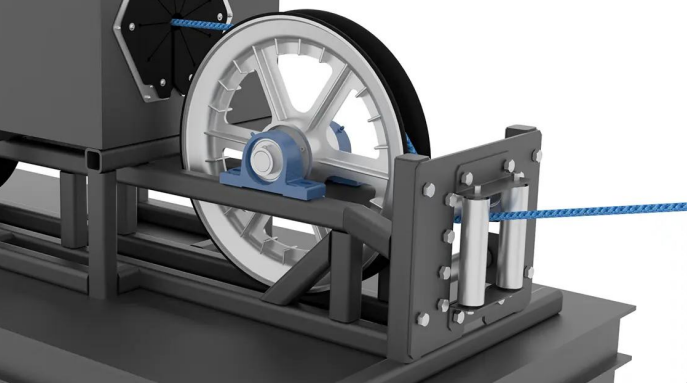

The Scope platform uses multiple cameras to capture a 360° image of the stringing line as it is pulled through the machine. The rope gets pulled at speeds up to 4 miles per hour, much faster than manual inspection, which occurs at around 2 miles per hour.

From there, Scope uses two neural networks to analyze the visual data, predicting the break strength of each segment of the rope, and detecting potential hazards, like cut strands, debris, and splices. These neural networks have been trained on thousands of break-strength tests in order to make accurate predictions and have been used to inspect over 100 million feet of stringing lines in North America.

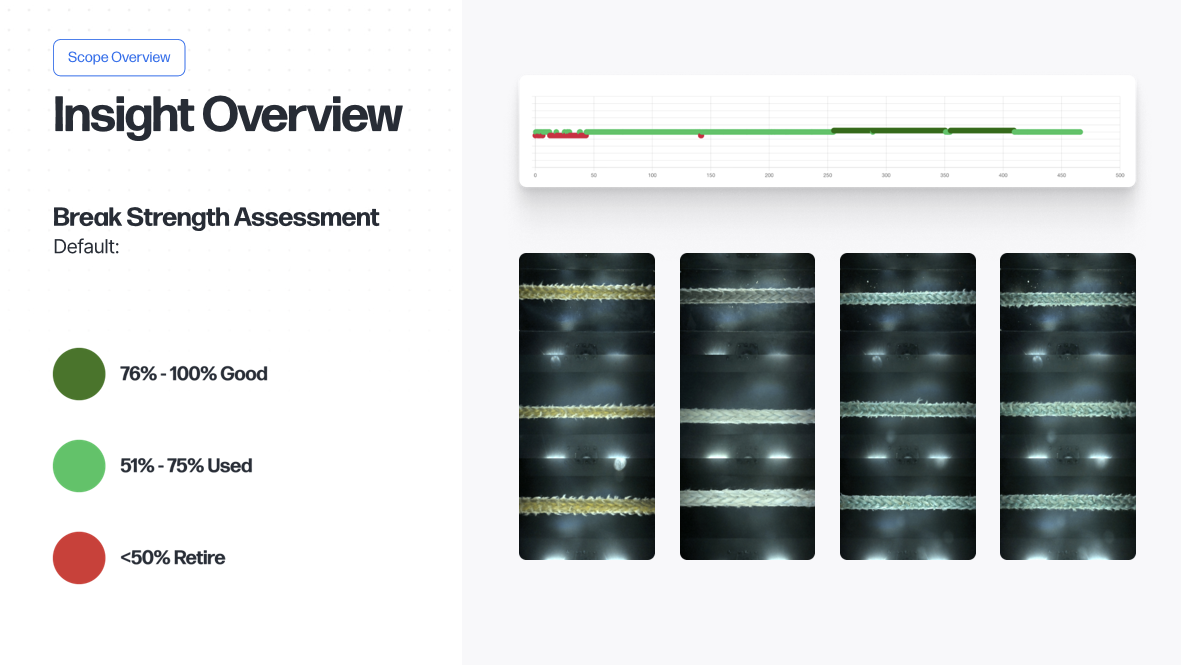

Stringing Line Health Index

As the stringing line is spooled through the device, Scope generates a comprehensive inspection report, showing owners the line quality across the entire stringing line, with 360° images of each insight identified.

What makes the system unique is its ability to pinpoint exact areas where the line is at risk. The report is generated in seconds and uses visual icons to show:

- Debris

- Cut strands

- Splices

The index also uses a color-coding system to determine the line’s break strength assessment. The report also shows:

- The exact distance where the insight was found

- The identification of that insight

- What repair action was taken for that line segment

- The total length of the stringing line

- All user entered information such as Manufacturer, Product, Diameter, etc.

- Continuous Improvement

Machine Learning Software

One of the unique capabilities of the Scope Inspection Platform is the machine learning nature of the software. As the system is used, insights are produced which are then reviewed by Scope subject matter experts. These insights are then used to refine the models for higher levels of accuracy and more nuanced identification of anomalies.

However, operators will still need to manually enter in the rope’s MFG, diameter, name, and fleet number.

What are the Benefits of AI-Enhanced Line Inspections?

Faster Inspection Times

Scope can operate at speeds up to 4 mph. While this doesn’t seem fast on the surface, it’s twice as fast as a manual inspection, which maxes out at 2 mph.

Higher Accuracy Ratings

While human line inspections are inherently subjective, Scope systems can identify potential line hazards with very high accuracy. While a human inspector can only see one side of the rope, Scope’s 360° line coverage enhances accuracy and removes judgement calls from the inspection process.

Instant Detailed Reports

Once the rope is spooled through Scope, it will generate a detailed inspection report within seconds, showing users the predicted rope integrity and images of the questionable areas. These reports can be downloaded and integrated smoothly into your internal systems.

Improved Line Repair Processes

Scope systems allow you to be proactive with your line repairs. Since it can identify potential line hazards, you can adjust ahead of time to replace or repair your stringing lines and not get caught off guard in the field.

And while manual inspections have no metric for quality or evidence of proper line care, Scope allows you to access historical reports of your line and set strength standards for your entire fleet.

Does the Scope System Replace Manual Inspections?

No, Scope systems are not a replacement for manual visual inspections. It is better to view Scope systems as a tool for trained technicians to use in their shops to speed up their processes—equipping them with real-time data.

While Scope systems can be used in the field, they are large machines and can be difficult to move around a job site. However, Scope is currently working on engineering a more compact model for in-field use.

Who Could Benefit from Scope Inspections?

Scope is being used daily by some of the largest electric utility corporations and contractors in the United States and Canada, improving the quality and documentation of repairs along with providing efficiencies in inspection and repair time. Scope has also been adopted by several high-profile rigging companies who provide services to these utility companies and contractors.

Any operator, technician, or linemen in the field can benefit from using Scope to enhance their manual inspection processes. As Scope explains, the system acts as a second set of eyes for their visual inspections that also automates all of the documentation.

Another benefit of using Scope is its ability to receive updates every other week to ensure the most recent and accurate versions of the software and models are leveraged from previous inspections across North America.

Final Thoughts

Scope takes the guesswork out of manual inspection processes, providing traceable health documentation on critical assets that can make or break an operation. By inspecting with Scope, companies are proactively addressing potential line hazards before they become catastrophic incidents that could cost millions. With costs running well into six-figures per hour for unplanned downtime, Scope insights give operators the data they need to make sure the stringing lines are truly field-ready.

In early 2025, Mazzella announced the deployment of Scope units to several of our facilities, including locations in Alabama, Illinois, and Ohio. These Scope units will help us improve, streamline, and speed up our stringing line inspections services for our customers.

Scope is another example of how the lifting and rigging industry is embracing technological advancements, and we hope you better understand how an AI-driven inspection service works and if it’s a good fit for your organization.

Contact a Mazzella specialists to learn more Scope inspections.

Copyright 2025. Mazzella Companies.