Year in Review: The Best Lifting and Rigging Articles of 2019

In this article, we look back at the ten of the most popular and best-performing lifting and rigging articles of 2019.

No matter what industry you’re in, there are plenty of products, procedures, and standards that you need to familiarize yourself with to do your job safely and effectively. If you and your team use rigging products, work at height, or use lifting equipment to move and handle loads, then you know how complicated it can be to stay on top of industry standards and regulations.

That’s why we originally created the Lifting & Rigging Learning Center. We have a full-time team dedicated to creating educational articles, videos, podcasts, and downloadable resources. We hope that you’ve used our Learning Center to help answer the questions you might have about material handling, rigging best practices, overhead cranes, fall protection, and so much more!

Our goal is always to partner with industry experts to put out educational resources, so you can:

- Make educated decisions when purchasing lifting or rigging equipment for your specific application

- Understand industry standards from OSHA, ASME, ANSI, CMAA, etc.

- Keep your lifting and rigging programs in compliance with industry standards

- Help improve the safety and efficiency of your workplace—including workers at height

In 2019, we’ve grown to over 1,200 blog subscribers, over 850 YouTube subscribers, our blog articles were viewed over 285,000 times and we have over 3,200 hours of video view time.

If you’ve read one of our articles, watched any of our videos, listened to a podcast, or downloaded anything from our website, we sincerely thank you. We continue to put out new content because we get such great feedback from those who read, watch, or listen to it!

If you missed out on some of our articles, or still need to subscribe to the blog, then we have you covered. This article will catch you up on the ten most popular and best-performing articles of 2019. Or, you can subscribe to our new monthly newsletter—The Monthly Rewind—to stay on top of the latest industry news, articles, videos, and more.

The Best Lifting and Rigging Articles of 2019

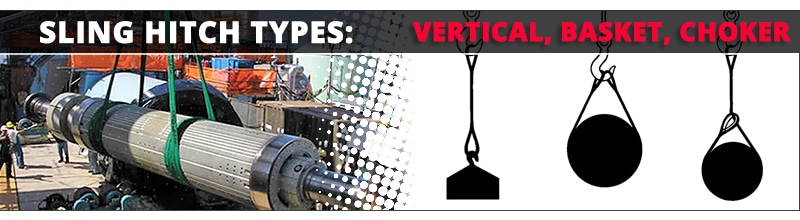

Which Sling Hitch Is Best for Your Lift? Vertical vs. Basket vs. Choker

Lifting slings are designed to be used in several types of hitches so that the best configuration can be used for handling and controlling a particular load. When putting a lift plan together, best practice is to always determine the best type of lifting sling and the type hitch you’re going to use prior to rigging the load.

In this article, we looked at:

- The three main types of hitches that can be used when rigging a load

- A visual representation of each type of hitch

- A comparison between lifting capacities for each hitch

- Best practices for rigging using each type of hitch

- Bridle (multiple leg) sling assemblies

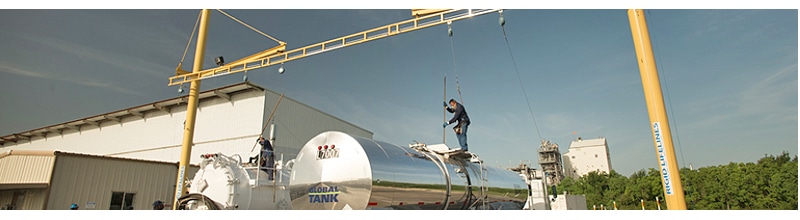

What Is a Rigid Rail Fall Protection System? Different Types & Design

OSHA regulations 1926 and 1910 mandate fall protection for employees working at heights of four feet (general industry), five feet (shipyards), six feet (construction) and eight feet (longshoring operations). When designing a fall protection system, there are many different factors that need to be considered. Understanding the ABCs of Fall Protection is a good place to start.

But, you should also know that there are engineered solutions available that can be designed specifically for your job site, facility, or application. Rigid rail fall protection systems are some of the most complete and innovative fall arrest systems available—for both indoor and outdoor applications.

Rigid rail systems are modular in design and can be configured in virtually endless lengths, spans, and fall protection coverage areas—ranging from large to small. A variety of track styles, mounting styles, and specifications allow you to create a durable and low maintenance fall protection system that will protect one or multiple workers at height.

In this article, we discussed the following:

- The definition of a rigid rail fall protection system

- The components of a rigid rail fall protection system

- The different types of permanent rigid rail solutions

- The different types of portable rigid rail solutions

What Are The Different Types of Lifting Hooks and Sling Hooks?

Are you planning your next overhead lifting project and need to specify the type of sling and rigging equipment you’ll be using? While it’s important to understand the best type of sling to use, it’s just as important to select the right type rigging hardware that will be connected to that sling. Choosing the right type of lifting hook that can be used will be determined by a number of different factors.

In this article, we discussed the different type of sling hooks that exist, including: eye hooks, clevis hooks, swivel hooks, hooks with latches, sorting hooks, foundry hooks, j-hooks, grab hooks, and barrel hooks.

In order to understand the best type of hook to use with your sling, you need to understand the following:

- The total weight of the load

- The type of load or material you will be lifting

- The type of sling being used

- The type of sling hitch being used

- The connection to the load – will you be using shackles, eye bolts, or does the load have engineered lifting points?

- The number of lifting points and overall distance between the lifting points

- The sling angle

Top 10 Safety Tips For Working At Height

Staying safe while working at height requires proper training, planning, and procedures for identifying, controlling, and removing potential hazards.

You can download our Top 10 Tips for Working at Height infographic or download it in an 11×17 poster format to hang in your job site or use as part of a tool box talk.

In this article, we looked at and expanded upon the top 10 considerations for working at height, including:

- Provide Fall Protection Training For Your Employees

- Perform a Job Safety Analysis

- Perform a Working at Height Risk Assessment

- Establish a Plan to Control or Eliminate Hazards

- Communicate Your Plan to ALL Workers On-Site

- Select the Appropriate Fall Protection Equipment

- Inspect Your Fall Protection Equipment Before Use

- Calculate the Total Fall Distance

- Double-Check Anchor Points

- Establish a Culture of Safety

Sling Protection Basics: How To Properly Maintain & Store Lifting Slings

Does it feel like you’re constantly scrapping out or replacing your lifting slings? Have you had a recent incident or near miss because of damaged or failed rigging? While there are best practices for rigging and lifting a load, an accident or product failure can often be traced back to misuse and abuse to rigging equipment during, or in-between, lifts.

When you don’t properly protect and maintain your lifting slings, you increase the chances of a dropped load, damaged property, injury, or worse.

Chain slings, wire rope slings, web slings, roundslings, synthetic rope, and metal mesh slings can all be used to safely and efficiently lift, move, and position a load. But, choosing the right type of lifting sling is dependent on a complete understanding of the application, the environment it’s being used in, and how the sling will be used to support and lift the load.

In this article, we provided you with some considerations and best practices for protecting, maintaining, and prolonging the service life of your lifting slings.

Buying a New Overhead Crane vs. a Used Overhead Crane: Which is Best?

For an upstart or rapidly growing business, buying used industrial equipment can provide a number of benefits without breaking the budget. Acquiring used equipment like forklifts, CNC machines, lathes, mills, or machine presses can add another dimension to production capabilities—which can lead to production efficiencies, improved product design, and eventually new growth opportunities.

For business owners who are handcuffed by an equipment budget, or may be looking to cut costs, a used overhead crane can seem like the perfect solution for their material handling needs. However, not all industrial equipment—especially overhead cranes—can easily be retrofitted from one application to another.

A used jib crane, workstation crane, or portable gantry crane could be retrofitted into a smaller shop to assist in light-duty manufacturing, assembly, or fabrication. But, bridge cranes and gantry cranes require precision engineering, and it can be challenging to find used crane equipment that:

- Matches the duty cycle of the original application to your lifting application

- Meets the span, lift height, and runway requirements for your building

- Installs within the confines of your existing building’s structure and supports

- Satisfies current safety codes and industry design standards (CMAA, OSHA, ASME, etc.)

We often get questions about whether it’s safe to install a used overhead crane, and if so, what types of problems you might encounter down the road. In this article, we provided an honest look at the advantages and disadvantages of buying and owning a used overhead crane system.

7 Things You Should Know Before Buying a Below-the-Hook Lifting Device

If you’re thinking about purchasing a below-the-hook lifting device, then you’ve probably realized there’s an inefficiency or a possible safety issue with the way you’re currently lifting materials.

“Below-the-hook lifting device” is a general term that can include a variety of engineered lifting beams, spreader beams, c-hooks, lifting tongs, vacuum lifters, or magnet lifters. These custom lifters offer more load control and support than traditional rigging. When used in conjunction with a crane and rigging equipment, a below-the-hook lifter can eliminate the hazard of a load tipping, sliding, or becoming unbalanced—as well as reduce low sling angles and the tendency of slings to crush or bend a load.

In this article, we walked you through seven different things you should know before buying a below-the-hook lifting device. If you’ve never gone through the consultation, quotation, and approval process, you’ll learn more about:

- How you can customize your below-the-hook device for your specific application and operating environment

- What information engineers and project managers need to know before they can provide a quote

- How you can help to make the design and approval processes go smoothly

- How ASME BTH-1 design parameters and basic physics may influence the design and specifications of your lifting device

- Why the approval process is so important to the success of the project

Different Types of Shackles: Anchor vs. Chain and Screw Pin vs. Bolt Type

A shackle is a u-shaped, load-bearing connecting device designed to be used with a removable pin. Shackles can be used in a number of different rigging and load securement applications to connect different types of lifting slings, chain, or rope to an object or to each other.

Shackles can be used in a variety of different applications, including:

- Rigging

- Towing or pulling

- Lifting

- Hoisting

- Tie-down

Just like lifting slings and sling hooks, shackles come in a number of different designs and configurations. It can be confusing to understand the correct type of shackle to use for your application, but you don’t want to guess or choose incorrectly—that could result in a rigging failure that could cause significant damage or injury!

In this article, we broke down the differences between the shape (bow) of the shackle as well as the different types of pins that are used for load securement. We also discussed the different types of material that a shackle can be made from and introduced some shackles designed for special applications.

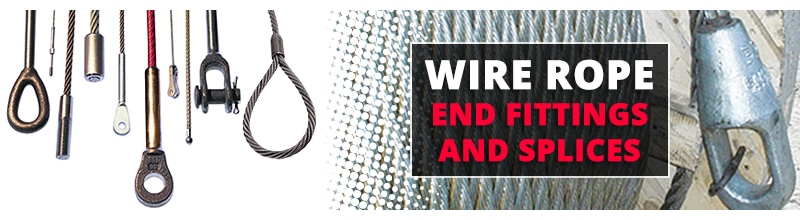

Wire Rope End Terminations: Sockets, Wire Rope Clips, and Splices

Whether for use on cranes or for other wire rope applications, it’s important to have a solid understanding of the rigging components that are being used to attach to and lift a load. These terminations are usually made by forming an eye or attaching a fitting, and are designed to be a permanent end termination on the wire rope where it connects to the load.

In this article, we explained what the following terms mean and how they can be used to terminate the end of a wire rope cable:

- Wire rope sockets—spelter sockets, swaged sockets, and wedge sockets

- Wire rope clips—U-bolt wire rope clips and double saddle wire rope clips

- Eye splices—mechanical (Flemish) and hand-tucked splices

- Wire rope end termination efficiencies

When you understand the construction and specifications of the wire rope you need, as well as the right type of end termination you need, you’ll be able to select the best performing and longest-lasting wire rope for the job at hand.

6 Things You Should Know Before Buying a Synthetic Web Sling

Web slings are one of the most popular types of lifting slings on the market. They’re strong enough to support heavy loads and are versatile enough to be used in several different applications and industries.

Web slings are also popular because they’re relatively inexpensive—if one gets damaged or gets removed from service after an inspection, replacement slings can be easily found at a reasonable price.

We often find that customers contact us to order a new web sling, they aren’t aware of all the different configurations that exist and may not know how to order a direct replacement. Even if they have the sling with them, it can be difficult to understand the part number on the tag, or decipher the abbreviations and specifications on the tag to order a direct replacement.

In addition to the weight of the load you’ll be lifting, there are several things you’ll need to know to get a web sling that meets the needs of your lifting application, including:

- Synthetic material – polyester or nylon

- The type of eye or fitting needed on each end

- The number of plies in the body

- Width of the sling body

- Overall length of the sling

- Additional cut, wear, or abrasion protection

In this article, we broke down some of the common terms used with synthetic sling construction and what information you can provide when requesting a quote during your next order experience.

Wrapping it Up

Again, thank you for everyone who has read, watched, listened, or downloaded any piece of educational content that we’ve put together. Thanks to those who have liked, shared, or commented on any piece we’ve posted on any of our channels, including LinkedIn, Facebook, Twitter, and Instagram.

And don’t forget to subscribe to The Monthly Rewind—an email newsletter that recaps all of the best articles, videos, industry news, and downloads from the previous month.

For 2020, we’d love to hear from you…if you have any ideas for future topics, or have any questions you’d like us to answer, please reach out to us at any time. You can contact us directly at marketing@mazzellacompanies.com.

From all of us at Mazzella, we want to wish you a happy holiday season, Happy New Year, and a productive and prosperous 2020!

Copyright 2019. Mazzella Companies.