How To Choose the Correct Clamp for Your Lifting Application

Is a clamp the correct below-the-hook device for your lifting application? We reached out to Caldwell / J.C. Renfroe to learn how to choose the correct clamp for your work.

Do you need a new below-the-hook lifting device and think a clamp could be the right fit? When it comes to lifting clamps, there are plenty of options. However, when choosing a clamp, how do you know you’re picking the correct one for your lifting applications?

To answer this question properly, we reached out to engineering manager Dale Kelly of Caldwell / J.C. Renfroe Lifting Solutions in Rockford, Illinois to help outline what you need to know before choosing a clamp.

In this article, we’ll look at the factors you need to consider when choosing a clamp for your overhead lifts, including:

- Hardness of the metal

- How you plan on lifting with a clamp

- What kind of jaw opening is needed for your application

- The environment will the clamp be used

- Confirmation upon receipt of the clamp

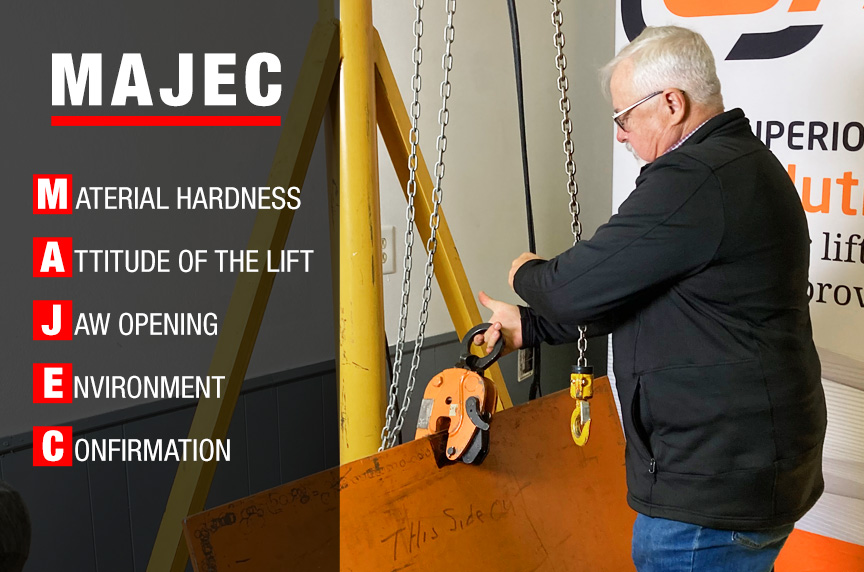

Lifting is “MAJEC”

Really, there is no “magic” involved in overhead lifting and material handling, at least there shouldn’t be. It is part art, part science in which all details must be considered beforehand to help ensure safe lifts. However, the acronym “MAJEC” will help you choose the correct clamp needed to safely make your overhead lifts.

The acronym, “MAJEC” stands for:

- Material Hardness

- Attitude of the lift

- Jaw opening

- Environment

- Confirmation through reading the manual, inspections and size (witness marks)

By going over the topics in the acronym, you can learn most of everything you need to know about how to choose the appropriate clamp for your application. Knowing this acronym will help develop a greater understanding of your:

- Materials

- Lifts

- Clamps

- Surroundings

- Processes

Breaking Down the Components of “MAJEC”

Metal Hardness

If the hardness of the metal is above 300 Brinell, which is measured on a machine or the certification that comes with the metal, the teeth of a clamp can’t penetrate into the steel. That will prevent the clamp from being able to do its job.

Caldwell / J.C. Renfroe has special clamps designed for plates above 300 Brinell, and those clamps are part of the non-marring series. They have a smooth jaw and a higher grip ratio that can grip the plate without slipping. Non-marring clamps have smooth jaws, and they will not leave marks on your plates. Therefore, it can be used on softer materials as well. This is especially true for plates that are sensitive to teeth marks where you need a polished surface.

If the plate metal is below 300 Brinell, clamps with teeth on them can be used for lifting. These teeth must remain sharp, and the properly sized clamp will grip the plate, penetrate the steel, and allow it to lift and do the job that needs to be done.

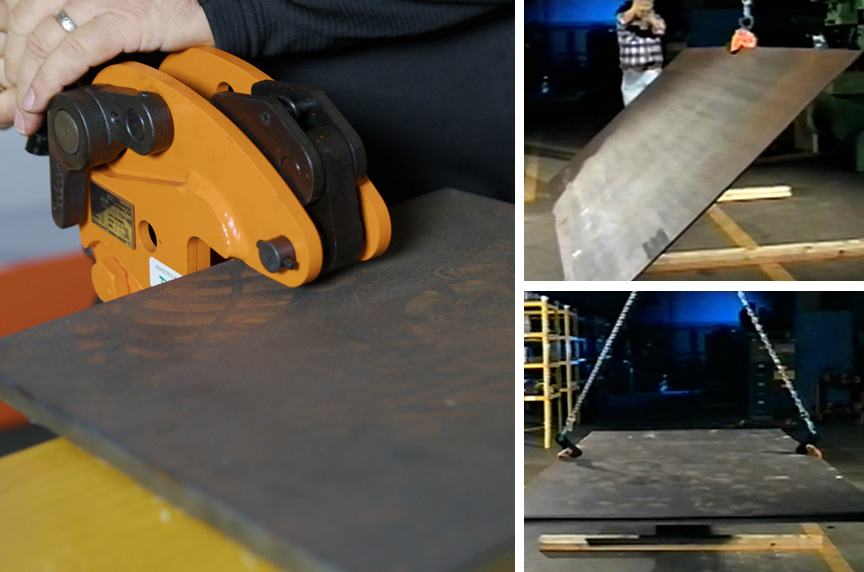

Attitude of the Lift

What “attitude” refers to is how you want to lift your plates. The following questions must be asked and answered to ensure you have the proper clamp for your lifts:

- Are you lifting plates vertically?

- Do you want to turn the plate during the lift?

- Do you need to flip the plates over during the lift?

- Is there another type of orientation that you must have to lift a plate?

If you want to lift a plate vertically, Caldwell / J.C. Renfroe’s FR clamp is a good choice. It’s a vertical-only lifting clamp meant to lift a plate on edge, straight up and down.

The next style of clamp is called the vertical plus 90. The Caldwell / J.C. Renfroe Model TL Clamp is rated to turn a plate from flat to 90° and back through the same angle. It has a locking lever on it that maintains constant pressure on the plate so the teeth can always penetrate during no-load conditions. Such conditions include when a plate is standing straight up and resting on the ground.

Also, Caldwell / J.C. Renfroe offers you clamps that can flip plates over completely. They have the following components that allow them to function properly:

- A pivoting jaw

- Lock

- Additional lock

Clamps for Special Lifting Conditions

The additional lock is a good safety feature, as when you’re flipping a plate completely over, if you happen to hit an obstruction, the clamp won’t unlock and disengage from the plate. The Caldwell / J.C. Renfroe JPA Model comes with a pivoting shackle that allows it to be used in pairs with a central lift point.

For plates that are lifted in a flat manner, meaning they are hoisted straight up and straight down, horizontal clamps should be used. You use these in pairs, and they are for lifting plates in a flat manner, straight up and straight down, and for transport through the shops. It does not turn, and there’s no side-loading allowed.

Caldwell / J.C. Renfroe has an SCPA model, and this clamp is rated to turn 180°. It has a pivoting shackle, so you can use it in pairs with a central hoist and a spreader beam when lifting a plate that’s standing vertically. As an added bonus, the robustness of this clamp is good for high vibration environments, and that’s where Caldwell / J.C. Renfroe clamps start to break down and become more specialized throughout the product line.

When speaking with your sales representatives, provide them with the information on how you need the plate moved.

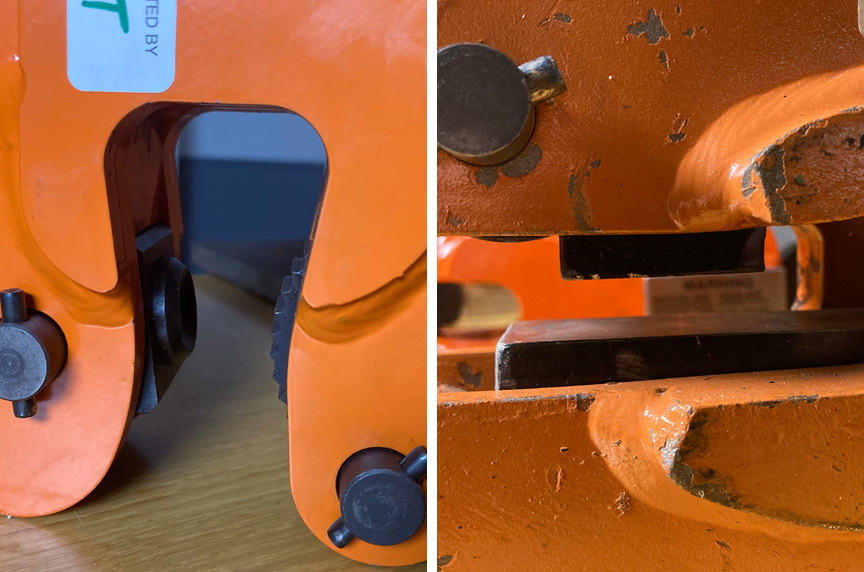

Jaw Opening

All Caldwell / J.C. Renfroe clamps are identified and have the jaw opening on the label. It is important that you always follow the restrictions listed on the clamp’s tags.

Remember, just because a plate fits in the jaws doesn’t necessarily mean it’s the appropriate clamp for a plate’s thickness. The reason is because once the clamp’s teeth penetrate, they can upset the metal, and now, the plate gets thicker and your plate can get stuck in the jaw. This will prevent the clamp from releasing.

Again, always follow the recommended jaw range that’s listed on the tag for each individual clamp.

Environmental Considerations

The next important item you need to discuss with your sales person is the environment you intend on using the clamp in. You need to identify if the clamps will be used in chemical conditions, sand conditions, and what kinds of temperatures (either extreme heat or cold), as all of those factors can affect the usability of the clamp.

All the Caldwell / J.C. Renfroe standard clamps have a temperature range of 0°F to 200°F. If the temperature range is beyond 0°F to 200°F, and it becomes too cold, the metal in the clamp can become brittle and cause the clamp to fail. When the temperature is too hot, it can damage the teeth and cause them to melt or lose their hardness and cause it to fail.

If your working conditions are outside of the 0°F to 200°F range, call your sales representative and tell them your desires to use a clamp in an environment that’s outside that range. Let the representative choose the appropriate clamp for the job. Caldwell / J.C. Renfroe does offer hot lift clamps that are capable of being used in environments up to 1,000°F.

Certain clamps shouldn’t be used in sand-blasting environments, and that includes screw clamps. The sand could get stuck and affect the threads. Acids and alkalines can attack the teeth and cause them to dull out. For these environments, Caldwell / J.C. Renfroe offers special materials that can withstand the caustic environments created by acids and give your clamps better lifespans for that work.

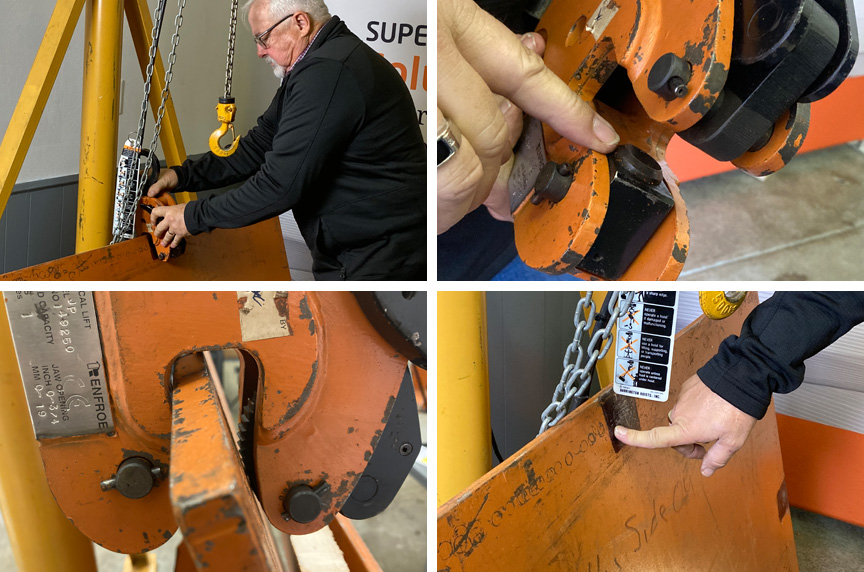

Confirmation

To confirm that you chose the right clamp, first you’ll want to read the clamp’s accompanying manual. Then, you’ll want to inspect your clamp to make sure everything is in operable condition, and that includes having a legible tag.

During the inspection, you’re looking to make sure the teeth are sharp, and the bolts holding the clamp together are tight.

Then, you will use your new clamp to conduct a test lift and check your “witness marks.” The first step in this process is outfitting yourself with the required PPE (personal protective equipment), which could include:

- Safety glasses

- Steel-toe boots

- Hard hat (where applicable)

- Anything else your company requires you to wear for safety purposes

“Witness marks” are the marks left on the plates after a load has been applied to your clamp.

During a test lift, you want take your clamp, apply it to your plate, tilting it at approximately a 20-30° angle and lock the lock handle. Then, you’ll tilt the clamp back up, leaving a 1/4” gap between the edge of the plate and the interior side of the jaw. This allows the clamp to seat properly.

Then, you’ll hook up the clamp to a hoist, and apply just enough load to lift the plate off the floor before returning the load to the ground. Once the plate is back on the ground, you’ll want to remove the clamp from the hoist, and disconnect it from the plate so you can inspect the witness marks. If you can feel an indentation, that clamp is suitable for your application.

When Would Clamps Not Be the Right Fit?

Sometimes, a clamp is not the right fit for your lifting application. In fact, if used improperly, clamps can be a hazard instead of a help.

This is especially true for the following plates:

- Diamond plate

- Coated plate

Caldwell / J.C. Renfroe recommends using clamps ONLY on plates that are clean and have no coatings so the clamp can get a proper engagement.

Where Can You Use Clamps for Overhead Lifts?

A good application for any Caldwell / J.C. Renfroe clamp is a clean metal plate of proper hardness that’s a flat surface.

Many of these clamps are used in shipyards for boat building. This is a good fit because the clamps help:

- Save time

- Increase efficiency

- Provide a safer work environment

How Can Mazzella Help With Your Below-The-Hook Lifting Devices?

If clamps are the correct below-the-hook device for your overhead lifts, Mazzella distributes several types of clamps based on your needs.

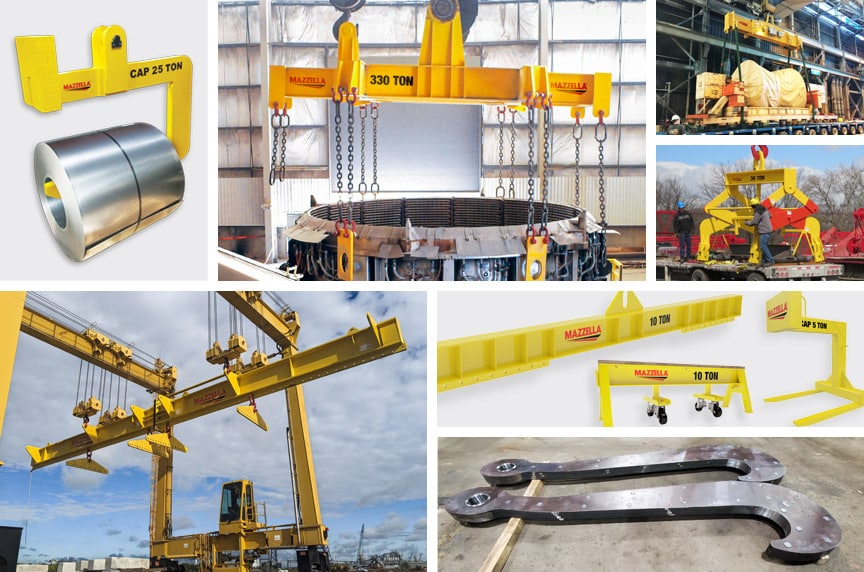

However, if clamps are not the correct product for you, we have more than 65 years of experience in designing and developing custom engineered products, below-the-hook lifting devices, and lifting attachments for use with all types of cranes. On-staff engineers and our commitment to the ISO 9001: 2015 standard guide us to continued success in manufacturing quality products and processes.

Mazzella understands the standards set forth by the American Society of Mechanical Engineers (ASME) for below-the-hook lifting devices, with an engineer who sits on the ASME B30.20 sub-committee. Also, we have the appropriate insurance coverage to provide you with a device that is certified and backed by the standards. Mazzella lifting devices will meet every OSHA (Occupational Safety and Health Administration) requirement and ASME standard.

We can design and fabricate all types of below-the-hook lifting solutions for any application—all of our work is done in compliance with ASME B30.20 Below-the-Hook Lifting Devices and ASME BTH-1 Design of Below-the-Hook Lifting Devices standards. Our products range from a common lift beam to an engineered special 150 lb. engine line lifter, and 330-ton electric furnace lifter.

Along with design and fabrication, we provide repair or recertification of below-the-hook lifting devices.

Click here if you need a repair or recertification of your lifting device.

Call us at 800.362.4601 or click here to specify your next below-the-hook project!

Below-the-Hook Lifting Devices

We have more than 65 years of experience in designing and developing custom engineered products, below-the-hook lifting devices, and lifting attachments for use with all types of cranes.

On-staff engineering and our commitment to ISO 9001: 2015 guides us to continued success in quality products and processes.

Copyright 2023. Mazzella Companies.