What Are Harrington’s EM / SEM Mini Electric Chain Hoists?

Why should you consider purchasing a Harrington EM / SEM Mini Electric Chain Hoist from Harrington? Simply put, after more than 150 years in business, Harrington understands the needs of the end-user and engineers quality machines that help improve productivity and safety.

Have your current electric chain hoists reached the end of their lifecycle and become more difficult / costly to repair? Do you want something easier to use and that will help increase productivity?

If you answered “Yes” to either question, the Harrington EM or SEM Mini Electric Chain Hoists may be the answer you’ve been looking for all along.

For more than 150 years, Harrington Hoists, Inc. has been providing you with solutions for your lifting and rigging needs.

In this article, we’ll answer the following questions about the Harrington EM / SEM Mini Electric Chain Hoists:

- What are the Harrington EM / SEM Mini Electric Chain Hoists?

- Which unique features do the Harrington EM / SEM Mini Hoists offer?

- What are the maintenance and service classes for the Harrington EM / SEM Mini Hoists?

- How do you get replacement parts for the Harrington EM / SEM Mini Hoists?

What Are the Harrington EM / SEM Mini Electric Chain Hoists?

The EM Mini Electric Chain Hoist is a three-phase hoist designed with an improved control system with Solid State Relay (SSR) technology. Also, with a microcontroller (MCU), the EM Mini will have increased service life and better safety functions.

This high-quality, low-headroom hoist is built for work in medium- to heavy-duty:

- Industrial settings

- Rental and repair shops

- Garages

The SEM Mini Electric Chain Hoist is a single-phase hoist designed for environments offering only single-phase power. Like the EM Mini, the SEM Mini has SSR and MCU technology, and is built to operate in limited-space areas

The Harrington EM / SEM Mini Electric Chain Hoists are able to handle your lifts in temperatures ranging from -4° to 104° F (EM) and 14° to 104° F (SEM). Additionally, they can operate in environments where humidity is 85% or less. The Harrington EM / SEM Mini Electric Chain Hoists can lift loads of 250 to 1,000 lbs. (EM) and 500 to 1,000 lbs. (SEM).

What Are the Unique Features of the Harrington EM / SEM Mini Hoists?

These medium- to heavy-duty (EM) and limited-space (SEM) hoists offer you several unique features and benefits, including:

- UL® listed

- High-performance motor brake

- Unique chain guide

- Forged carbon steel hooks

- Solid state relay board

- Sleek rounded IP65 body

- Friction clutch

- Grease-packed gearbox

- Nickel-plated load chain

- Chain container

- Standard swivel hook

- Low profile upper limit switch

UL® Listed

These hoists are certified and listed to UL 1340 “Standard for Hoists” and CSA 22.2 No. 33 “Construction and Test of Electric Cranes and Hoists” standards.

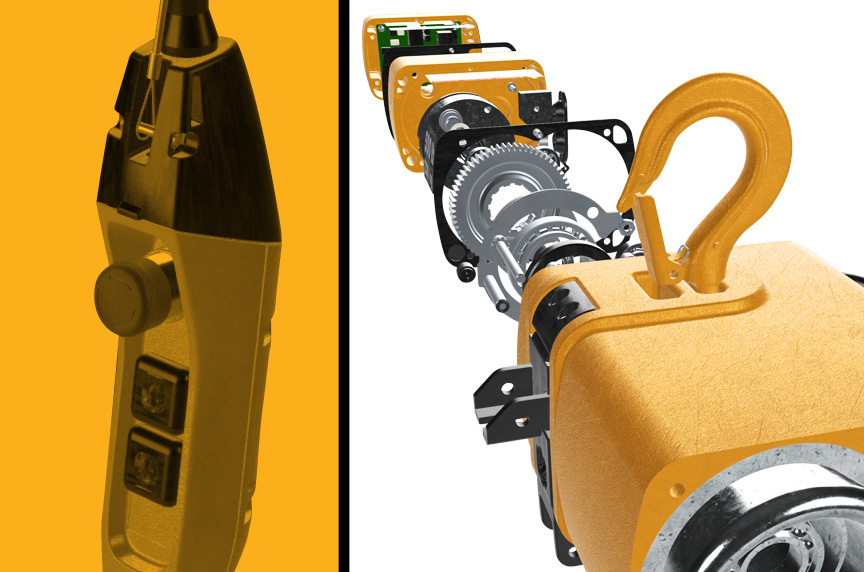

High-Performance Motor Brake

The electromagnetic brake is fast acting and has a durable current. The brake comes with a five-year warranty.

Unique Chain Guide

The unique chain guide discharges the chain from the side of the hoist body, which prevents tangling when winding up the slack chain. The chain is heat-treated for increased durability.

Forged Carbon Steel Hooks

When under excessive loads, the forged carbon steel hooks will open gradually and not fracture. The ball bearings allow for smooth rotation, and the bottom hook offer you 360° swivel capabilities. The heavy-duty hook latches are standard.

Solid State Relay Board

The SSR board has no mechanical contacts, which allows for an extended service life. The microcontroller provides protection from:

- Fast reverse

- Phase loss and reversal (EM only)

- Overcurrent

- Overtemperature

- Overvoltage

SSR boards come with electronic overload limiters and LED error indicators.

Sleek Rounded IP65 Body

The compact and rugged die-cast aluminum body has no sharp edges. The superior ingress protection makes it suitable for both indoor and outdoor applications.

By being IP65 rated, the EM / SEM Mini Electric Chain Hoists are totally protected against dust and protected against low-pressure jets of water from all directions with limited permitted ingress.

Friction Clutch

The rotor-integrated friction clutch outside of the load path provides consistent performance over a wide temperature range.

Grease-Packed Gearbox

The grease-packed gearbox is important particularly in demanding industrial applications.

Nickel-Plated Load Chain

In these hoists, Harrington used Grade 80, super strength load chain that has superior corrosion resistance.

Chain Container

An optional black canvas chain container is designed with two secure attachment points.

Standard Swivel Hook

The standard swivel hook prevents twists in the rigging. An optional fixed hook is available.

Low Profile Upper Limit Switch

The upper limit switch protects the hoist from overwinding and offers exceptional headroom.

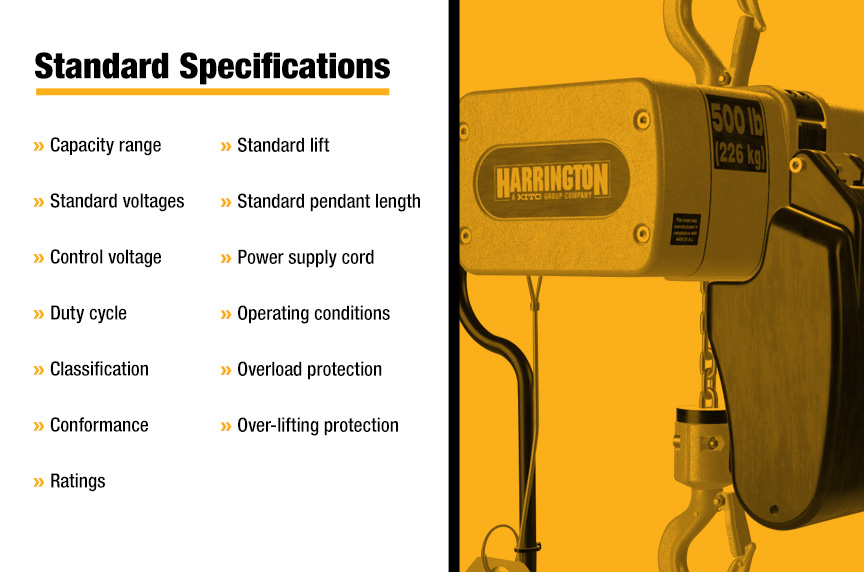

What Are the Standard Specifications for Harrington EM / SEM Mini Electric Chain Hoists?

In the manual for the EM / SEM Mini Electric Chain Hoists, Harrington outlines the following specifications for each of these products, including:

- Capacity range

- Standard voltages

- Control voltage

- Duty cycle

- Classification

- Conformance

- Ratings

- Standard lift

- Standard pendant length

- Power supply cord

- Operating conditions

- Overload protection

- Over-lifting protection

Capacity Range

For the EM hoists, the capacity is 250 to 1,000 lbs. The SEM has a capacity range of 500 to 1,000 lbs.

Standard Voltages

The EM hoist has several standard voltages:

- (200-230)-3-60

- 200-3-50

- (380-460)-3-60

- (380-400)-3-50

The SEM hoist has two standard voltages:

- (115-120)-1-60

- (220-230)-1-60

Control Voltage

Both hoists have a DC24V control voltage.

Duty Cycle

The EM and SEM hoists each have a duty cycle of 30 minutes.

Classification

Both hoists have received the following classifications:

- ASME H4

- ISO M5

- FEM 2m

Conformance

These hoists conform to the UL 1340/CSA 22.2 and ASME B30.16 Overhead Underhung and Stationary Hoists standards.

Ratings

Both hoists are IP65 rated.

Standard Lift

Each hoist comes with a standard lift length of 10’. However, other lengths are available.

Standard Pendant Length

Standard pendants hang approximately 4’ above the hoist’s fully extended bottom hook. However, longer lengths are available.

Power Supply Cord

Each hoist comes with a 15’ power cord. However, longer lengths are available.

Operating Conditions

The Harrington EM / SEM Mini Electric Chain Hoists are able to handle your lifts in temperatures ranging from -4° to 104° F (EM) and 14° to 104° F (SEM). Additionally, they can operate in environments where humidity is 85% or less.

Overload Protection

This is standard for both hoists through the SSR board.

Over-Lifting Protection

Each hoist has a standard protection with the friction clutch outside of the load path, as well as an upper limit switch.

What Are the Maintenance and Service Classes for Harrington EM / SEM Mini Electric Chain Hoists?

Every box shipped containing a Harrington product will include an owner’s manual. The owner’s manual will tell you how to determine the maintenance schedule for each of their products, along with other important information.

As the owner of the hoist, you have to figure out which of the following classifications applies to your applications:

- Normal Service

- Heavy Service

- Severe Service

Normal service is defined as operations with randomly distributed loads within the rated load limit or uniform loads less than 65% of the rated load limit for more than 25% of the time.

Heavy service is defined as operations within a working load limit which exceeds normal service. That is classified as hoists whose lifts exceed 65% of the rated load for more than 25% of the time or randomly distributed loads for over 25% of the time.

Severe service involves normal service and heavy service under abnormal operating conditions like weather or constant running.

Inspection Requirements

Once you determine what service classifications your hoists fall into, there are two kinds of inspections:

- Frequent inspection

- Periodic inspection

Frequent inspections are performed by an operator or other designated person at the facility:

- For normal service, frequent inspections would be needed monthly

- Under heavy service, weekly to monthly

- For severe service, daily to weekly

Periodic inspections are performed by designated persons. Harrington partners with Mazzella to provide these services. These inspections occur:

- At least yearly for normal service

- Semiannually, at least, for heavy service

- Quarterly for severe service

If you need your hoists repaired, you can contact Mazzella, which is a Harrington repair center, or speak with Harrington directly if you’re not sure who does repairs in your area.

By tracking the serial number of the product, Harrington can determine who you purchased the hoist from and guide you to that distributor first. If that company doesn’t do repairs, Harrington would put you in contact with a service repair center in your area.

How Do You Find Replacement Parts for EM / SEM Mini Electric Chain Hoists?

You cannot purchase replacement parts directly from Harrington, as the company only sells products through distributors.

Mazzella is a master parts distributor for Harrington and carries many products to fulfill your needs.

For any further questions, you can contact your local sales representatives. If you go to Harrington’s website under the “Resources” page, there is a “How To Buy” link. You can type in the first three numbers of your zip code, and the “How To Buy” program will pull up the information for the local territory representative.

How Can Mazzella Help With Your Hoists?

Mazzella is your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

If you are not looking to replace a hoist, we also have a Hoist Repair Department available to get your hoist back up and running. We provide in-house repair of electric, lever, manual chain, and wire rope hoists.

We offer you the following with our hoist service division:

- Experienced and qualified technicians assigned to perform hoist inspections and repairs

- Repairs and testing that comply with ASME B30.16 Overhead Underhung and Stationary Hoists and ASME B30.17 Cranes And Monorails (With Underhung Trolley or Bridge) specifications

- Static and dynamic testing

- Test certificates that are available electronically or a hard copy on paper

- Repairs and testing performed at our facility

- Load testing of all repaired hoists and pullers

- Repairs and tests to theatrical standards upon request

Call us at 800.362.4601 or click here if you need hoist units, parts, or repairs!

Harrington Hoists

Mazzella is your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

The Harrington Hoists product line includes electric and air powered chain hoists and trolleys, electric wire rope hoists and trolleys, lever hoists, manual hand chain hoists, push and geared trolleys, overhead cranes, crane accessories and a full line of replacement parts. Harrington Hoists, Inc. is ISO 9001 certified.

Copyright 2023. Mazzella Companies.