What Is the Harrington TCL Lube Free Air Hoist, & How Can It Help You?

Why should you consider purchasing a Harrington TCL Lube Free Air Hoist from Harrington? Simply put, after more than 150 years in business, Harrington understands the needs of the end-user and engineers quality machines that help improve productivity and safety.

Are you looking to purchase a new air hoist that not only stands up to difficult tasks under less-than-ideal working conditions, but also, is environmentally friendly?

Have your current air hoists reached the end of their lifecycle and become more difficult / costly to repair? Do you want something easier to use and to increase productivity while reducing your impact on the environment? The Harrington TCL Lube Free Air Hoist may be the answer you’ve been looking for all along.

For more than 150 years, Harrington Hoists, Inc. has been providing end-users with solutions for their lifting and rigging needs, and their most popular product was designed to hold up to difficult conditions with quiet operation, and minimal vibration.

In this article, we’ll answer the following questions about the Harrington TCL Lube Free Air Hoist:

- What is the Harrington TCL Lube Free Air Hoist?

- Does the Harrington TCL Lube Free Air Hoist come in different models?

- What is the maintenance and service class for the Harrington TCL Lube Free Air Hoist?

- What unique features does the Harrington TCL Lube Free Air Hoist offer end-users?

- How do you get replacement parts for the Harrington TCL Lube Free Air Hoists?

What Is the Harrington TCL Lube Free Air Hoist?

Harrington’s TCL Series Lube Free Air Hoists are operational without air supply lubrication, which leaves the environment free of oil mist from the air exhaust. The TCL Series hoists are recommended for use in any area where oil mist cannot be tolerated, such as in:

- Food production

- Chemical environments

- Pharmaceutical industries

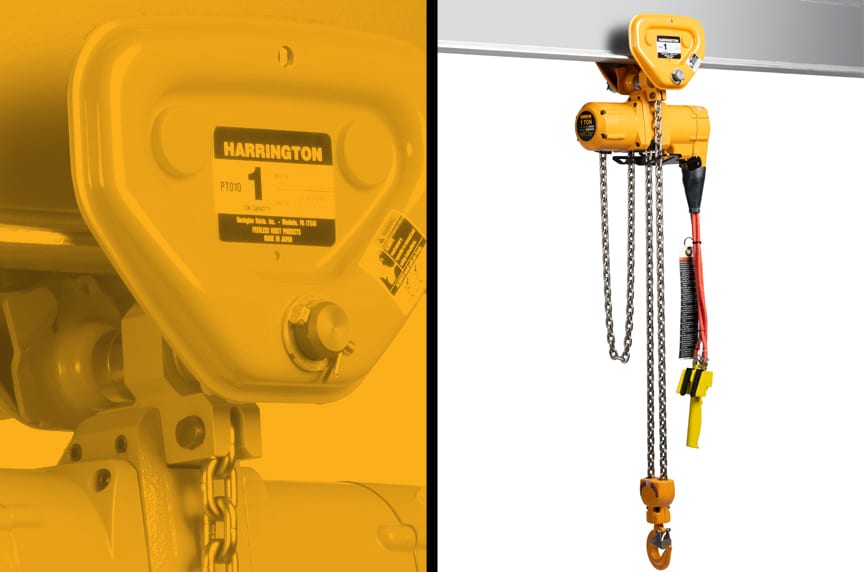

For added mobility, pairing Harrington’s MCL air powered trolley with the TCL Lube Free Air Hoists leads to easier transport of medium to heavy loads. These hoists can be mounted to a Harrington push trolley (PT) or geared trolley (GT) for lighter or more infrequent moves.

The Harrington TCL Lube Free Air Hoists are able to handle your lifts between ¼ and 6 tons, depending on the type of hoist you purchase.

Does the Harrington TCL Lube Free Air Hoist Come in Different Models?

Yes, the Harrington TCL Lube Free Air Hoist comes in different models to address a variety of customer needs based on lifting capacity and type of suspension.

Overall, there are 10 hoist models of this hoist line. The hoists come in capacities of ¼, ½, 1, 3 and 6 ton capacities in both the hook suspension and air powered, push, and geared trolleys constructions.

What Are the Unique Features of the Harrington TCL Lube Free Air Hoists?

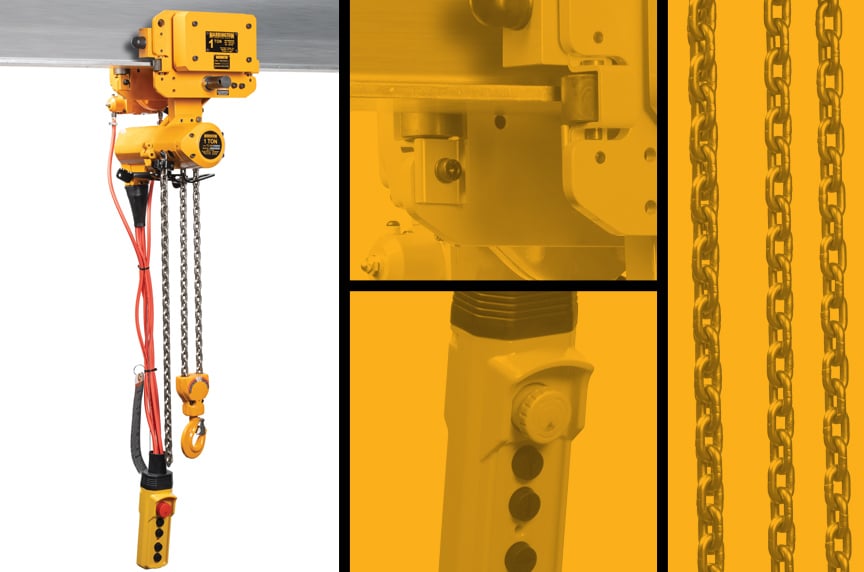

Hoists with Pendant and Cord Controls and Hook Suspension

These hoists offer precise load positioning with either pendant or cord control, and have several features and benefits that will help you in the field.

Unlimited Duty Cycle

These hoists are built for continuous operation.

Spring-Loaded Multi-Vane Motor Design

This feature allows for very fine feathering control. Although fast at full throttle, it can be slowed down by the end-user to allow for precise load positioning.

Pilot air control and spring-loaded vanes are keys to fine feathering.

Extremely Fast Lifting

This is meant to assist in applications where speed is critical.

Low Noise Levels

This adds increased comfort to the operator during use, and also, could prevent hearing damage.

Nickel-Plated Load Chain

Having a nickel-plated load chain increases resistance to:

- Corrosion

- Abrasion

- Wear

Lubrication Free

This feature is important, particularly for applications where a clean environment is needed.

For the ¼-1 ton capacity hoists, they offer:

Extremely Compact & Lightweight Body

The cast aluminum body allows for easy operation, transportation, and storage.

External Speed Adjustment Screw

No special tools are required to set specific speeds. The screws can be adjusted simply by removing rubber caps over the bolts and using a basic screwdriver to make the necessary changes for speed.

Adjustable Lifting and Lowering Speeds

Having adjustable lifting and lowering speeds allows for increased production capabilities.

Heavy-Duty Disc Motor Brake System

This feature is important because it allows for reliable load support.

For the 3-6 ton capacity models, they offer end-users:

Overload Limiter

The adjustable load limiter detects overload automatically, and blocks air flow for lifting.

Cast Iron Housing

This adds strength and durability to your hoists.

Powder Coated Finish

This has proven to be a helpful feature, as it is weather resistant for use in harsh environments.

Internal Disc Brake

Having the disc brake in the body of the hoist and not exposed protects it from harsh environments.

The standard hoist specifications include:

- Capacity range of ¼-6 tons

- Lift height of 10’ (with longer lifts available)

- Controls that are approximately 4’ above the hoist’s fully extended bottom hook (longer lengths available)

- 60-90 psi air supply requirement

- Maximum five micron air filter or finer required

- Temperature range of 14°F to 140°F

- Optional canvas or steel chain containers

- Air inlet points of

- ½” NPT* for ¼-1 ton hoists

- 1” NPT* for 3-6 ton hoists

- Air supply hose minimum sizes of

- ½” for ¼-1 ton hoists

- ¾” for 3-6 ton hoists

*NPT stands for the National Pipe Thread Tapered

Hoists with Air Powered, Push, and Geared Trolleys

The Air Powered trolleys offer:

Unlimited Duty Cycle

These hoists are built for continuous operation.

Spring-Loaded Multi-Vane Motor Design

This feature allows for very fine feathering control. Although fast at full throttle, it can be slowed down by the end-user to allow for precise load positioning.

Pilot air control and spring-loaded vanes are keys to fine feathering.

Drop Stops & Rubber Bumpers

This feature is designed to ensure safe operation.

Side Guide Rollers

The rollers provide additional stability and smooth travel.

Versatile Wheels

The wheels can fit flat or tapered beam flanges.

Trolley Muffler

This produces low noise levels and helps protect the hearing of the hoist operator.

Lubrication Free

This feature is important, particularly for applications where a clean environment is needed.

For the ¼-1 ton capacity hoists, they offer:

Extremely Compact & Lightweight Body

The cast aluminum body allows for easy operation, transportation, and storage.

For the 3-6 ton capacity models, they offer end-users:

Cast Iron Housing

This adds strength and durability to your hoists.

Powder Coated Finish

This has proven to be a helpful feature, as it is weather resistant for use in harsh environments.

Internal Disc Brake

Having the disc brake in the body of the hoist and not exposed to elements protects it from harsh environments.

The standard hoist specifications include:

- Capacity range of ¼-6 tons

- Pendant control only

- Controls that are approximately 4’ above the hoist’s fully extended bottom hook (longer lengths available)

- 53cfm at 60-90 psi air supply requirement

- Maximum five micron air filter or finer required

- Operating conditions

- Temperature range of 14°F to 140°F

- Humidity at 85% or less

- Optional canvas or steel chain containers

- Air inlet port of ¾” NPT*

- Air supply hose minimum sizes of

- ½” for ¼-1 ton hoists

- ¾” for 3-6 ton hoists

*NPT stands for the National Pipe Thread Tapered

The manual trolleys offer:

Shafts

The standard shafts fit a wide range of beams, and longer shafts are available for larger beams. Spacers allow end-users to make easy adjustments.

Wheels

The all-steel wheels with sealed ball bearings can fit flat or tapered beam flanges.

Capacity Range

Push trolleys have capacities of ¼-6 tons. Geared trolleys have capacities of 3-6 tons.

Control Option on Hoist

There are options for pendant (TCLP) and cord (TCLG) controls.

Standard Hand Chain Length

On geared trolleys, the chain hangs down approximately 2’ less than the fully extended bottom hook. Longer lengths are available.

The standard hoist specifications include:

- Capacity range of ¼-6 tons

- Push trolley ¼-6 tons

- Geared trolley 3-6 tons

- TCLP and TCLG pendant and cord controls

- On geared trolleys, the standard hand chain length is approximately 2’ less than fully extended bottom hook (longer lengths are available)

What Is the Maintenance and Service Class for Harrington TCL Lube Free Air Hoists?

Every box shipped containing a Harrington product will include an owner’s manual. The owner’s manual will tell end-users how to determine the maintenance schedule for each of their products, along with other important information.

As the owner of the hoist, you have to figure out which of the following classifications applies to your applications:

- Normal Service

- Heavy Service

- Severe Service

Normal service is defined as operations with randomly distributed loads within the rated load limit or uniform loads less than 65% of the rated load limit for more than 25% of the time.

Heavy service is defined as operations within a working load limit which exceeds normal service. That is classified as hoists whose lifts exceed 65% of the rated load for more than 25% of the time or randomly distributed loads for over 25% of the time.

Severe service involves normal service and heavy service under abnormal operating conditions like weather or constant running.

Inspection Requirements

Once you determine what service classifications your hoists fall into, there are two kinds of inspections:

- Frequent inspection

- Periodic inspection

Frequent inspections are performed by an operator or other designated person at the facility:

- For normal service, frequent inspections would be needed monthly

- Under heavy service, weekly to monthly

- For severe service, daily to weekly

Periodic inspections are performed by designated persons. Harrington partners with Mazzella to provide these services. These inspections occur:

- At least yearly for normal service

- Semiannually, at least, for heavy service

- Quarterly for severe service

If you need your hoists repaired, you can contact Mazzella, which is a Harrington repair center, or speak with Harrington directly if you’re not sure who does repairs in your area.

By tracking the serial number of the product, Harrington can determine who the customer purchased the hoist from and guide you to that distributor first. If that company doesn’t do repairs, Harrington would put you in contact with a service repair center in your area.

How Do You Find Replacement Parts for TCL Lube Free Air Hoists?

End-users cannot purchase replacement parts directly from Harrington, as the company only sells products through distributors.

Mazzella is a master parts distributor for Harrington and carries many products to fulfill customer needs.

For any further questions, you can contact your local sales representatives. If you go to Harrington’s website under the “Resources” page, there is a “How To Buy” link. You can type in the first three numbers of your zip code, and the “How To Buy” program will pull up the information for the local territory representative.

How Can Mazzella Help With Your Harrington TCL Lube Free Air Hoists?

Mazzella is your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

If you are not looking to replace a hoist, we also have a Hoist Repair Department available to get your hoist back up and running. We provide in-house repair of electric, lever, manual chain, and wire rope hoists.

We offer you the following with our hoist service division:

- Experienced and qualified technicians assigned to perform hoist inspections and repairs

- Repairs and testing that comply with ASME B30.16 Overhead Underhung and Stationary Hoistsand ASME B30.17 Cranes And Monorails (With Underhung Trolley or Bridge) specifications

- Static and dynamic testing

- Test certificates that are available electronically or a hard copy on paper

- Repairs and testing performed at our facility

- Load testing of all repaired hoists and pullers

- Repairs and tests to theatrical standards upon request

Call us at 800.362.4601 or click here if you need hoist units, parts, or repairs!

Hoists, Hoist Parts, & Repairs

We are your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

We are also one of the largest authorized stocking master parts depots for Columbus McKinnon (CM) Companies. We feature Budgit, Coffing, Acco / Wright, Yale, Shaw-Box, and Harrington…just to name a few. Call our Parts Department for your hoist parts needs.

If you are not looking to replace a hoist unit, we also have a Hoist Repair Department available to get your hoist back up and running. We provide in-house repair of electric, lever, manual chain, and wire rope hoists.

Copyright 2022. Mazzella Companies.