How do I select and install trolleys for manual and powered hoists?

While this may seem like a simple question, it has a complicated answer, one that manufacturers have provided through intensive training programs for its distributors. The goal of the training was to understand standards set forth by OSHA (Occupational Safety and Health Administration) and ASME (American Society of Mechanical Engineers), and how to install these trolleys to meet those requirements to keep your overhead lifts as safe as possible.

In this article, you’ll learn about:

- Types of trolleys and beams

- Selection and installation of trolleys for manual and powered hoists

- Proper procedures for trolley use and inspection

- Operation of the trolley and its brakes

- Disassembly and reassembly of trolleys

- Performing a routine inspection

- Troubleshooting trolley issues

- Properly fitting a trolley to a beam

Types of Trolleys

Trolleys are available for underhung lug-mounted hoists and underhung hook-mounted hoists for monorails and single girder cranes.

Trolleys for Lug-Mounted Hoists

A lug-mounted hoist requires mechanical fasteners, including varying types of hardware and pins, to attach it to the trolley. The hoist gets attached directly to the trolley rigidly. That eliminates any flexing between the trolley and the hoist.

Underhung trolleys for monorails and single girder cranes for lug-mounted hoists include:

- Push / Pull Trolley

- Motor-Driven Trolley

- Hand-Geared Trolley

Trolleys for Hook-Mounted Hoists

A hook-mounted hoist is one that uses a hook suspension to join the hoist to the trolley. These hoists are two individual components. The trolley is one individual unit, and it will have an eye at the bottom of it to which you can attach a hook.

Underhung trolleys for monorails and single girder cranes for hook-mounted hoists include:

- Push / Pull Trolley

- Motorized Trolley

- Motorized Tractor Drive Trolley

- Hand-Geared Trolley

Tractor Drive Trolleys pull themselves along the bottom of the beam hanging from the wheels on the flange.

All of CM’s trolleys are manufactured to the ASME B30.16 Overhead Underhung and Stationary Hoists standard. Section 16-1.2.1: Mechanical Design states “the hoist and accessories shall be designed to withstand all stresses imposed under normal operating conditions while handling loads within the rated load (capacity).”

What To Know about Beams?

Trolleys are designed to fit specific beam flange sizes. Thus, you may not easily be able to convert trolleys from one flange size to another. While there could be two trolleys that fit the same beam, one trolley might be at its maximum adjustability range and the other might be at its minimum adjustability range.

Sometimes, price dictates the type of trolley you’ll purchase, but also, it could come down to availability or capacity.

Switching a trolley from one flange to another requires removing certain pieces of hardware and adjusting the trolley side plates.

Standard Beams

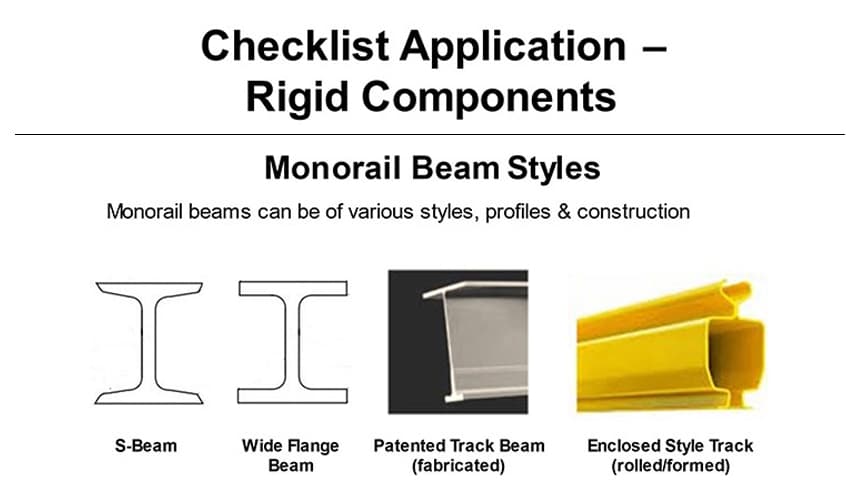

There are many types of beams in use on the market, and they include:

- AISC (American Institute of Steel Construction) “S” Section Beams, also known as “I” Beams

- AISC “W” Section Beams, which are also referred to as “H” or “WF” (Wide Flange) Beams

The “S” and “I” beams have a flange slope of 9°, while “W,” “H,” and “WF” beams have a flange slope of 0° to 2°.

In some cases, these different beams can accept a universal wheel fit, but there are times when a universal wheel won’t work properly. That would depend on the capacity and the size of the trolley.

Patented Track Beams

Patented Track Beams are manufactured tracks.

The inside track where the wheel of the trolley would ride typically is harder than the traveling surface of an “S” beam or the “WF” beams. That gives more longevity to the trolley wheel and will not be as susceptible to wear. That will save you downtime and money because the trolley will not need to be repaired or replaced as often as it would while installing and running on an “S” or “WF” beam.

While that is a big strength, there are some disadvantages to using a patented track beam. The wheels on the track are harder to match the hardness of the track. Those wheels tend to be narrower, so there is less contact between the beam and the wheel. You won’t have as much friction to stop, so the trolley’s braking system needs to be up to date and stronger than a normal system.

Patented Track Beams are used a lot in curved sections because it tends to be stronger and have better longevity than a standard “WF” or “S” beam. These beams can be shaped and formed in different ways.

Selecting the Correct Trolley

In order to choose the right trolley for your beam, you either have to know or have an evaluation done to gather the following information about your working environment:

- Beam Shape

- “S” or “W” Section

- Patented Track

- Fabricated

- Beam Depth / Height

- Flange Width

- Flange Thickness

- Curve Radius and Type

- Measures radius

- 90°, 180°, or “S” curve

Disassembly and Reassembly of Trolleys

When any kind of maintenance is done, trolley wheels must be checked because they’re subject to the most wear. Just like the tires on a car, when in use, trolley wheels are the first component that will experience wear.

The wheel bearings will need to be lubricated periodically. For more regular use, the bearings will need to be lubricated more often. Conversely, less frequently used trolleys will not need to have their bearings lubricated as often.

Wheels should be lubricated with a manufacturer-supplied or recommended grease or oil.

Trolley Wheels

Trolley wheels are made from medium carbon-forged steel or cast iron. They have a dual-tapered tread to run on both “S” and “W” Section beams, and are equipped with precision ball bearings.

Patented Track Wheels

Patented track wheels have a narrow flat tread, and are heat-treated to 425 BHM to meet patented track requirements.

Trolley Construction

With many motor-driven trolley models, they will include VFDs (Variable Frequency Drives). Many manufacturers offer these units on their trolleys. The VFDs help ramp up or ramp down a trolley gradually, which will reduce high-impact collisions against the ends of the beams.

The speeds can be adjusted based on your specific needs. If you’re moving a hot material or a liquid (i.e. acids, plating compound), you don’t want it to spill. This is where the slow ramp up and ramp down comes into play. It helps you avoid a potential incident.

Key things to understand with trolley construction include:

- Structural steel side plates

- Drop stops bolt-on option on Shaw-Box models

- Rubber bumpers are optional

- The side plates are load-bearing, so they need to be inspected periodically

- Right angle worm gear reducers

- Provides braking to stop unit within 10% of rated speed

- Squirrel cage induction motors

- Similar features as hoist motor, except NEMA Design B motors

- VFD duty standard

- Controls

- Single-speed contactor standard

- Two-speed contactor and VFD available options

With trolleys, the following must be inspected periodically:

- Trolley wheels (plain or geared)

- Drop stops

- Space washers with nuts

- Warning label

- Suspension bolt nuts

- Load bracket

- Side plates (plain or geared)

- Suspension plate

When trolleys are purchased, the manufacturer will put in enough spacers and washers in the unit so you can configure that trolley from the minimum flange thickness allowed to the maximum. You cannot add additional non-OEM (Original Equipment Manufacturer)-supplied spacers or washers to the trolley to fit on a bigger beam. Instead, you need to purchase a different trolley.

The suspension bolts are designed only to go to the maximum flange thickness that the trolley is made for.

***Remember, load testing of a trolley is recommended when load-bearing components are repaired / replaced / altered.

How Do I Properly Fit a Trolley to a Beam?

Once it is determined that the trolley is compatible with the beam, the next step is to adjust the width of a trolley to fit the beam.

In order to adjust the width of the trolley, you want to:

- Remove one set of locking nuts on one side of the trolley

- Remove the washers / spacers from the shaft

- Space the trolley wheels the appropriate distance to fit the designated flange using the washers / spacers

- Set the distance on one side of the trolley and leave the other side loose

The next step includes:

- Placing the trolley on the selected flange with assistance from a person, jack, tow motor, or another hoist

- You may be attaching a lug-mounted trolley separately or with the hoist affixed to the trolley, so this assembly can be heavy SO USE CAUTION.

- Assembling the last side plate to the trolley with the appropriate washers / spacers and tighten the remaining locking nuts

- Checking the clearance between the flange of the trolley wheel and the edge of the flange of the beam

- The gap should measure 1/8” to 3/16” greater than the flange width or what the manufacturer recommends

- Ensuring the trolley moves along the beam freely, and make adjustments as needed

- If the trolley is powered, test that the controls match the movements of the trolley, as well as the hoist

How Can Mazzella Help You with Your Hoists and Trolleys?

In working to select and install a new trolley for your manual or powered hoists, you must understand:

- The different types of trolleys and beams

- How to select and install trolleys for hoists

- Proper procedures for trolley use and inspection

- Operation of the trolley and its brakes

- Disassembly and reassembly of trolleys

- Performing a routine inspection

- Troubleshooting trolley issues

- Properly fitting a trolley to a beam

Mazzella has been in the lifting and rigging industry since 1954, and is a distributor of trolley and hoist products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications, as well as trolleys that work with multiple hoist types.

If you are not looking to replace a hoist unit, we also have a Hoist Repair Department available to get your hoist back up and running. We provide in-house repair of electric, lever, manual chain, and wire rope hoists.

Our Hoist Repair Department will ensure you receive:

- Experienced and qualified technicians assigned to perform hoist inspections and repairs

- Repairs and testing in compliance with ASME B30.16 Overhead Underhung and Stationary Hoists and ASME B30.17 Cranes & Monorails With Underhung Trolley or Bridge specifications

- Static and dynamic tests

- Test certificates that are available electronically or paper will be provided

- Load tests for all repaired hoists and pullers

Also, we can repair and test to theatrical standards upon request.

Call us at 800.362.4601 or click here to purchase new trolleys or hoists, or discuss needed repairs for your current lifting and rigging equipment.

Hoists, Parts, & Repairs

We are your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

We are also one of the largest authorized stocking master parts depots for Columbus McKinnon (CM) Companies. We feature Budgit, Coffing, Acco / Wright, Yale, Shaw-Box, and Harrington…just to name a few. Call our Parts Department for your hoist parts needs.

Copyright 2021. Mazzella Companies.