How Do Crosby | Straightpoint Load Cells Make Your Overhead Lifts Safer?

Do you know the weight of the load you’re about to lift? Crosby|Straightpoint has a way for you to take the guesswork out of your lifting and eliminate the need for manual calculations in the field with either their Radiolink Plus or Wireless Load Shackle load cell devices and Bluelink Bluetooth Dynamometer.

How do you calculate the weight of an overhead lift?

Well, if you didn’t have a monitoring device like a load cell, what would you be doing?

Guessing.

And what should be eliminated from the process of lifting a load?

Guessing.

You want to eliminate hazards as often as possible when lifting loads. If you don’t, it could lead to catastrophic failure. In a worst-case scenario, a failed lift could damage the load, or more importantly, could cause injury or death.

Crosby | Straightpoint load cells are focused on taking the guesswork out of lifting. They want you to know your load’s exact weight and eliminate the risks associated with not using a load cell/dynamometer.

In this article, we’ll look at the following:

- What is a Crosby | Straightpoint load cell?

- Types of load cells/dynamometers

- How load cells and dynamometers are used in lifting

- Common problems with…

- Common misconceptions about…

- Maintenance/Repairability

What Is a Crosby | Straightpoint Load Cell?

Using a load cell or dynamometer is all about knowing how much you’re going to pick up.

The load cell will indicate how much weight that you have on your hook. Strain gauge technology measures the microscopic strain on the body of the load cell. Then, the results are converted into a pound, kilogram, kilonewton, or metric ton reading.

Types of Crosby | Straightpoint Load Cells

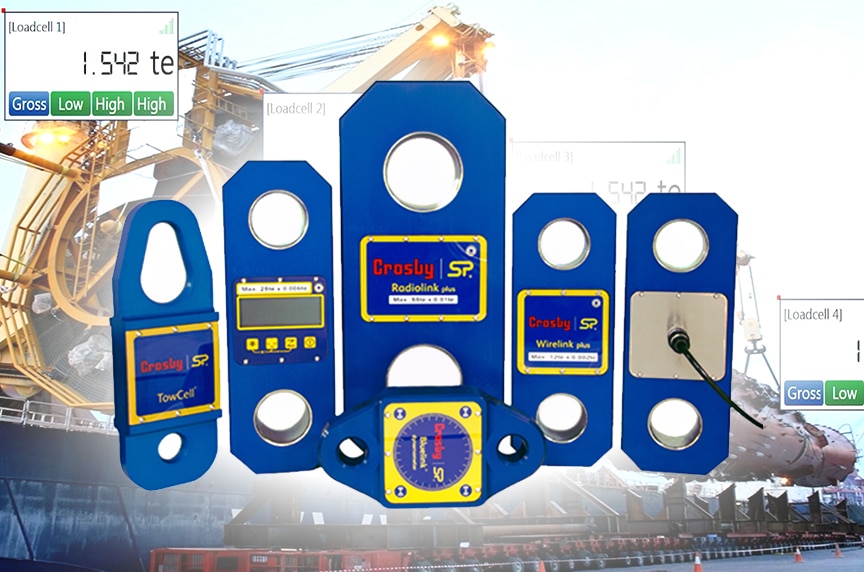

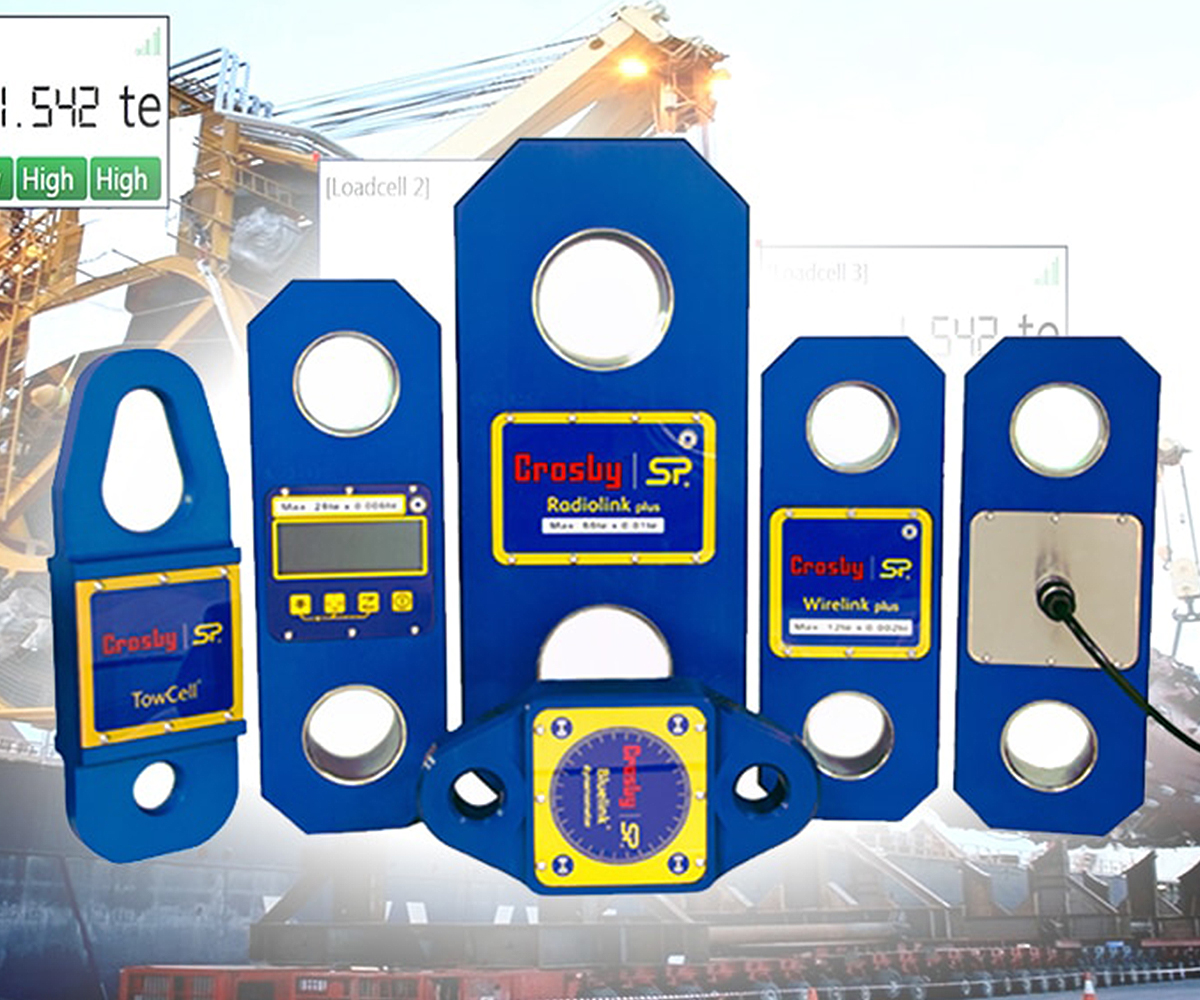

The Radiolink Plus

This is Crosby | Straightpoint’s link-style load cell with shackles on the top and bottom. This is their most commonly used load cell for monitoring loads. In their opinion, monitoring load weight should be done for every lift.

You put one shackle on the hook and attach the rigging to the bottom shackle. A wireless handheld device receives the information, which helps keep operators a safe distance away from the lift.

The wireless handheld device has a 1,000-meter range, which equates to more than 3,300 feet. Although Crosby | Straightpoint has never seen a need to be that far away from a lift, it means the Radio Frequency (RF) signal from The Radiolink Plus remains strong at varying distances from the load.

Reading the Results

Sometimes, you will see load cells with an integral screen, which creates a couple of issues in some cases:

- Puts the operator in close proximity to the lift

- Is difficult to read from far away

Because of space limitations, the screen is typically an inch or less tall, and sometimes, not backlit. You’ve either got to be really close to the load and put yourself at more risk for serious injury/death, or utilize a lower-tech option like binoculars.

Binoculars still may not be enough, as it could be difficult to tell apart similar-looking numbers on the screen. Results obtained this way may not be able to answer if the crane/rigging gear being used to complete the task is suitable to perform safe lifts.

The Radiolink Plus load cell is strictly wireless. There is no screen/read-out actually built into the structure of the cell. The Radiolink Plus remains functional if gouged or dinged because it features a completely polycarbonate front plate.

If your load cell’s screen is damaged, it can no longer be used without first going in for assessment/repair.

The Wireless Load Shackle

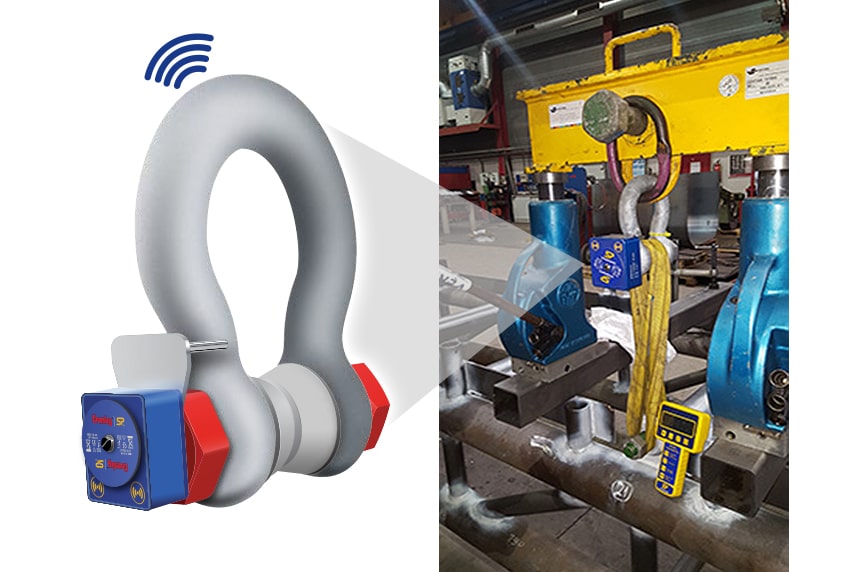

The Wireless Load Shackle utilizes Crosby G2130 and G2140 bolt type shackles to monitor loads for an efficient solution.

Low headroom applications, permanent installations, and heavy lifts are areas where a Wireless Load Shackle makes sense to use. Crosby | Straightpoint makes the wireless load shackles in varying capacities up to 1,500 metric tons.

Example:

Say you have a 400-ton Radiolink Plus load cell with a 400-ton shackle on top, and a 400-ton shackle on the bottom. It requires so much headroom and is so heavy with all those components together that it decreases the ease of use.

Solution:

You could use the Wireless Load Shackle at 400 tons, connect it to your rigging and hook, and monitor your lift.

Monitoring the Results

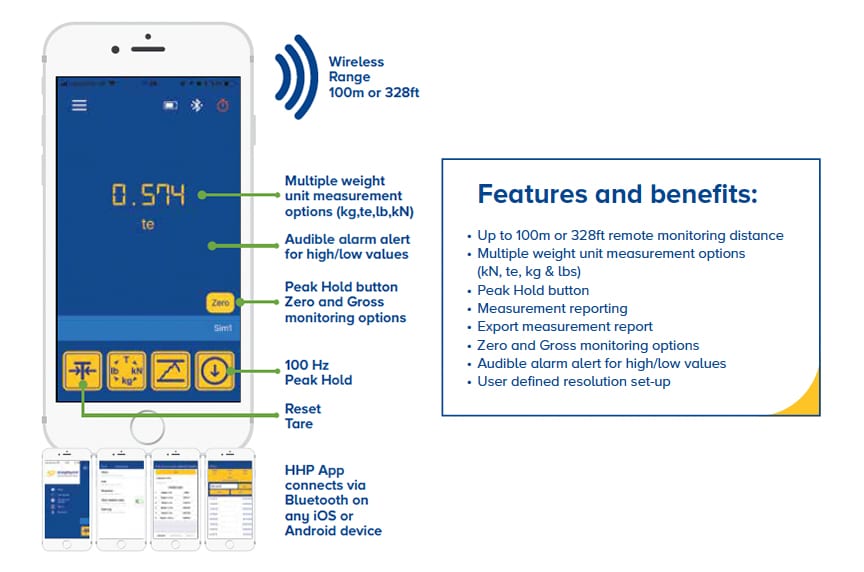

The Wireless Load Shackle offers either a long-distance Radio Frequency version monitored on a handheld device with Crosby | Straightpoint’s Insight software (designed for Windows-based devices), or a Bluetooth version monitored with their free app. The HHP app is available on Android or iOS platforms.

The Bluetooth version of the Wireless Load Shackle has a communication range of about 100 meters or 328 feet. However, the presence of other frequency devices in range of the load cell (including, but not limited to wireless crane controls), the signal could be weakened or easily disrupted.

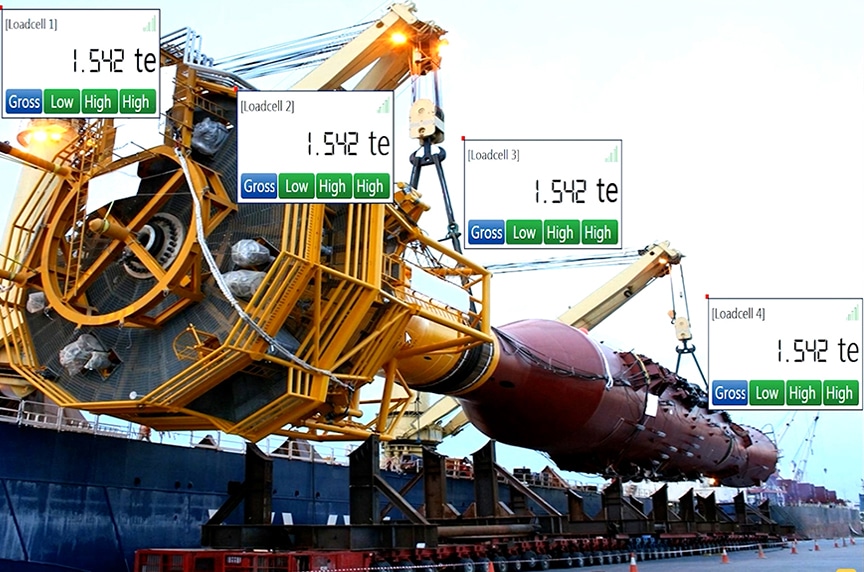

You can monitor the long-distance Radio Frequency version of the Wireless Load Shackles from the handheld device, which can monitor up to four devices at one time. If you have a four-point lift and you need four Wireless Load Shackles, you only need the one handheld device (or Insight software) to see the individual loads or access another screen that gives you the total weight of the load.

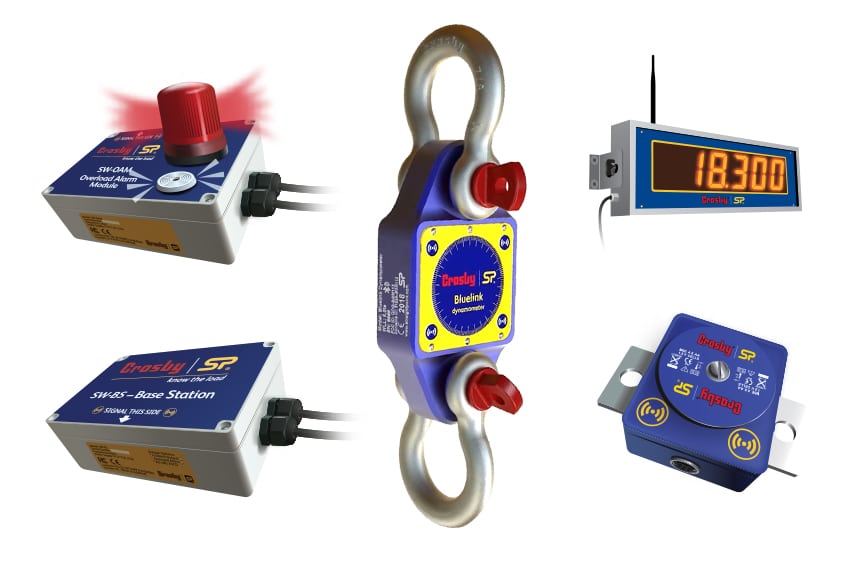

Following the power-on, the handheld device will connect to the load cell(s). If there is only one load cell, it will display the reading in a single screen mode. As the weight of the load increases, the amount on the display will increase. If an overload occurs, the handheld will display “OVERLOAD,” and a 90db alarm on the handheld will sound.

In addition to the weight, the Crosby | Straightpoint handheld device will be monitoring each load cell’s signal strength and ID.

Differences in load cells

The biggest difference between the link-style Radiolink Plus and Wireless Load Shackle is accuracy.

A link-style load cell, like the Radiolink Plus, is 0.1% +- tolerance of capacity.

If you’re using the Radiolink Plus on a 12-metric ton load, which is 26,000 pounds, you’re going to have a +- tolerance of only 26 pounds.

The Wireless Load Shackle used on the same 12-metric ton, 26,000-pound lift has a 1.0% +- tolerance. Now, you’re talking about 260 pounds.

Although the Wireless Load Shackle will not be as accurate as the Radiolink Plus, there are environments and applications where headroom is absolutely critical, and you won’t be able to use a Radiolink Plus.

***When customers go from no load monitoring to 1% +- tolerance, that’s a great improvement.

Other Load Cell Monitoring Devices

Crosby | Straightpoint has customers who call and say, ‘Hey, I’m working on an auto crane on the side of a truck. It’s 1-ton. I don’t need to be 200 feet away. I just need something that’s going be reliable, and lightweight, where I can put it in use and see the results on my phone using an app.”

Enter the Bluelink Bluetooth Dynamometer.

The Bluelink Bluetooth Dynamometer has a 6½-ton capacity. It’s a Bluetooth-only device meant to be used with Crosby | Straightpoint’s HHP app, which is free on the Android and iOS platforms and the customer can monitor the loads on their phones.

The app also has a record and log feature for when you need to record a particular measurement for later referral. Once logged into the app, it will allow you the convenience of exporting the details of the logged measurement(s) either to your mobile device, or send it to a particular email address in a spreadsheet format.

Monitoring the Results

Crosby | Straightpoint designed the Bluelink Bluetooth Dynamometer to connect to up to eight devices simultaneously.

Let’s say the foreperson wants to monitor the load while the crane operator is executing a lift. The operator doesn’t have to pass off the phone or wireless handheld device to the foreperson because the app allows him/her to monitor the load themselves.

As a double-check, if there’s a project engineer who wants to monitor the lift as well, all three can check the progress of the lift through the app without having to share and risk losing wireless display devices.

The app allows for teamwork and project specialization with one person executing the lift and focusing on the load. That person is watching the crane, watching the operation of the lift and controlling it.

By having a second person monitor the load cell, they will give an audio cue to the operator to keep executing the lift or to stop because the crane is overloaded.

For a solo working environment, The HHP app has an audible alarm that’s programmable, so the operator really knows when the load is nearing the crane’s capacity to help avoid overload events.

Training to Use Systems

Every product that comes in the Crosby | Straightpoint carry case has a QR code where customers can get the manual. The QR code takes customers to a landing page where they can see videos of how to use the product effectively.

Crosby | Straightpoint really worked hard to make these tools user-friendly. That means being able to open the case, turn on the device simply by hitting the power button and getting to work.

Best Fits

Some tools are job specific.

The Wireless Load Shackle and Radiolink Plus have their strengths and weaknesses, but can be used in different applications, different industries, and to different capacities.

Some uses include:

Logging Industry

Loggers came to Crosby | Straightpoint and wanted to use the Wireless Load Shackle as they were pulling logs up the side of the mountain.

Overhead Cranes

Typically, in a warehouse, headroom can be an issue during a lift. There are thousands of overhead cranes in the United States with no or limited load monitoring. The Wireless Load Shackle is a hook, and Crosby | Straightpoint offers an LED display that’ll show the weight. They’re four-inch tall letters so you can see how much you’re lifting.

Auto Crane

Here, load cells are used to make sure lifting specialists don’t overload the pedestal crane.

If you’re lifting a load, and you don’t know how much it weighs, that’s a perfect application for a load cell. There’s a multitude of opportunities to rig loads safer than they are right now simply by knowing how much you’re lifting.

Limitations

Crosby | Straightpoint’s load cells are designed to operate between 14°F (-10°C) and 122°F (50°C).

If there’s a customer making a lift in sub-zero temperatures, it’s probably not a fit for Crosby | Straightpoint’s load cells.

Conversely, in hot forge foundries, customers will put a load cell on a crane that’s getting up to 150°F, and others have said it’ll flash a temperature of 250°F. Crosby | Straightpoint doesn’t have an effective solution for something that hot.

Crosby | Straightpoint does make custom project load monitoring solutions, so special applications can be reviewed for capabilities.

If someone has a hazardous environment where they’re using spark-resistant cranes and hoists and explosion-proof equipment, Crosby | Straightpoint has an ATEX (Atmosphere Explosible)-rated load cell that can be used in those hazardous environments. The specialized load cell must be marked by ATEX and has to be ATEX-approved.

***Remember to have conversations with your rigging specialists and you’re reaching out to manufacturers to understand what you’re getting into because the equipment/tools business is not a “one-size-fits-all, out-of-the-box” application. Do your research on what you’re about to rig BEFORE you rig it.

Common Problems with Load Cells

Misinformed End-Users

The most common problem that Crosby | Straightpoint sees is the thought that using readings from load cells or weight measurement is an exact science. There’s a reason why you weigh more at the doctor’s office than your home scale. Any monitoring device/load cell has a +- tolerance.

If a customer calls and says, “I just received your Radiolink Plus. We turned it on, we picked it up, and it does not match the integrated LMS (load monitoring system) in my crane.”

The service technician will ask:

- When did you last have your crane’s LMS recalibrated?

- What is the +- tolerance of that crane’s LMS?

They may not know the +- tolerance and can’t find when it was last calibrated. At that point, Crosby | Straightpoint advises them to use the Radiolink Plus load cell, reference the supplied certificate of calibration, and trust that the recently calibrated device will give you an accurate reading.

***Remember to monitor your loads with timely and accurately calibrated equipment.

Bad Positioning

End-users standing underneath the load cells is another common problem that Crosby | Straightpoint sees in the field.

There are some applications where a customer can be too close to a load. Although the Radiolink Plus has a 1,000-meter range, the Radio Frequency band goes up and down, and really close to the load, there can be high peaks and low valleys in the RF signal.

If the customer is standing too close to the load with the handheld monitoring device, that Radio Frequency can jump over the receiver and may not get a signal. Remember, wireless load cells are designed to be used at a safe distance from the lift.

Misconceptions About Load Cells

The biggest misconception on these load cells is that they’re both Radio Frequency and Bluetooth, and that’s not the case.

Crosby | Straightpoint offers products that are either Radio Frequency (long distance 1,000-meter range) or Bluetooth (100-meter range).

After buying a Radiolink Plus, some customers have called and said, “I’ve got the yellow handheld, but I can’t connect my phone to it.”

That’s because it’s not a Bluetooth device.

Maintenance/Repairability of Load Cells

These load cells are an investment in safety, and they’re a monetary investment for your company.

Crosby | Straightpoint has recalibrated load cells that have been in use for as much as 25 years, and it is recommended that they receive annual recalibration. With any rigging piece of hardware, it’s going to depend on the environment. If you’re using it seven days a week and 12 hours a day, your company might require a quarterly recalibration to ensure the load cell is maintaining the most accurate +- tolerance.

Crosby | Straightpoint most commonly sees this product needing repair after being shock loaded or overloaded.

With a shock load or overloaded lift, it’s possible one of the string gauges can become unbonded from the metal. At that point, the load cell’s results are going to jump around. If that happens, you’ve got to send it for evaluation, and if possible, repairs.

Wrapping it Up

By reading this article, you have learned about different types of Crosby | Straightpoint load cells, as well as the strengths, weaknesses and limitations, best uses, and ease of maintenance/repairability of these devices.

We hope this article helps inspire you to utilize a more accurate way of monitoring your loads, and thus, improve the safety and secure delivery of loads on your jobsite.

Keep having those conversations with lifting specialists and product manufacturers. By having a good understanding of your lifting plans, and what they should be, you will be able to determine if products like load cells are a good fit for your company are the most important next steps.

The end goal is for you to have safer, more efficient lifts.

Click here to contact a Mazzella lifting specialist today for all of your lifting needs.

❯ Crosby|Straightpoint Load Cell Dynamometers

Radiolink plus BLE is designed to be rigged with Crosby standard shackles. Straightpoint’s DNV-GL type approved wireless tension load cell is capable of weighing and dynamic load monitoring capacities from 1t to 500t (all in stock).

❯ Lifting Products

We carry a complete line of lifting products, including a wide range of overhead crane blocks, wire rope sheaves, ergonomic material handling equipment, lifting clamps, and hydraulics … just to name a few!

Copyright 2021. Mazzella Companies.