3-3 | Basic Inspection Criteria

<p>Whether you’re doing rigging inspections in-house or working with a third-party rigging inspection service, it’s very important for the inspector to understand what abuse the chain is seeing and inspect it accordingly.</p>

Whether you’re doing rigging inspections in-house or working with a third-party rigging inspection service, it’s very important for the inspector to understand what abuse the chain is seeing and inspect it accordingly.

Prior to inspecting, clean chains with a non-acid / non-caustic solvent so that marks, nicks, wear, and other defects are visible. With regard to inspection criteria, chain damage typically falls into one of five categories and critical damage will be obvious to a properly trained inspector.

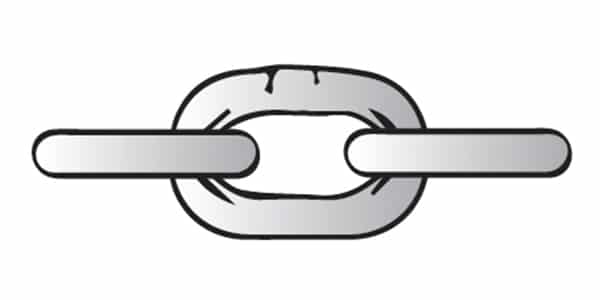

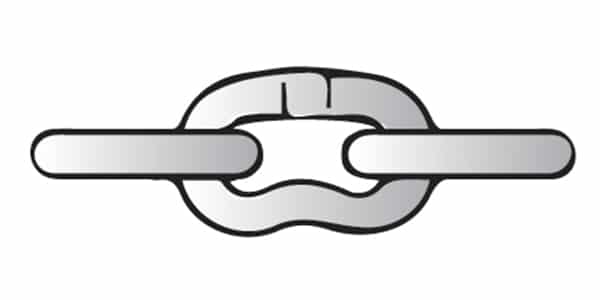

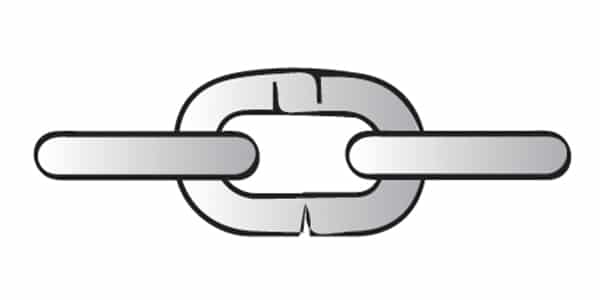

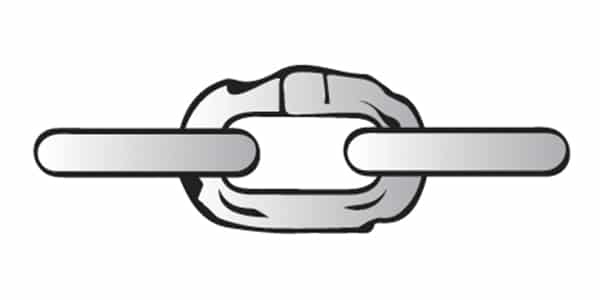

Wear

Localized Bending

Shearing / Cracks

Nicks or Gouges

Stretching

An alloy steel chain sling shall be removed from service if any of the following conditions are present:

- Missing or illegible sling identification

- Cracks or breaks

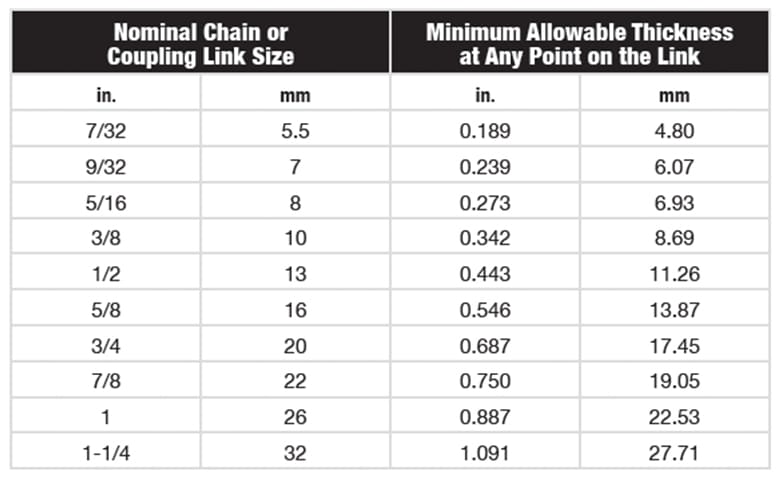

- Excessive wear, nicks, or gouges. Minimum thickness on chain links shall not be below the values listed in the table below:

Minimum Allowable Thickness at Any Point on a Link

- Stretched chain links or fittings

- Bent, twisted, or deformed chain links or fittings

- Evidence of heat damage

- Excessive pitting or corrosion

- Lack of ability of chain or fittings to hinge freely

- Weld splatter

- For hooks, removal criteria as stated in ASME B30.10

- For rigging hardware, removal criteria as stated in ASME B30.26

- Other conditions, including visible damage, that cause doubt as to the continued use of the sling