Measuring Crane Span and Runway Length

<p>Having a clear understanding of the space available in your building, the existing building supports that the crane can be installed on, and any overhead obstructions, will help you lay out the design criteria and expectations for any crane manufacturer who bids on the project.</p>

Having a clear understanding of the space available in your building, the existing building supports that the crane can be installed on, and any overhead obstructions, will help you lay out the design criteria and expectations for any crane manufacturer who bids on the project.

You should familiarize yourself with the following measurements prior to meeting with an overhead crane manufacturer:

- Runway beam size

- Runway rail size

- Crane span

- Runway length and distance between runway supports

- Building clearances

The more information you can gather upfront, the more information the crane manufacturer will have to take back to their engineering team to put an accurate quote and project specification together. Also, the better you understand the design and specification requirements for your own crane system, the better equipped you’ll be to compare the different quotes you receive against the project criteria.

What You’ll Need to Measure for an Overhead Crane Installation

When you’re gathering your materials so you can start recording measurements, we recommend using the following tools:

- Tape Measure – A 25’ to 30’ foot tape measure is perfectly fine

- Laser pointer – An inexpensive one can be found at hardware or home improvement stores for $65-70. More expensive ones with longer ranges are typically $130-150.

- Notepad and pen or pencil

- Building plans or drawings

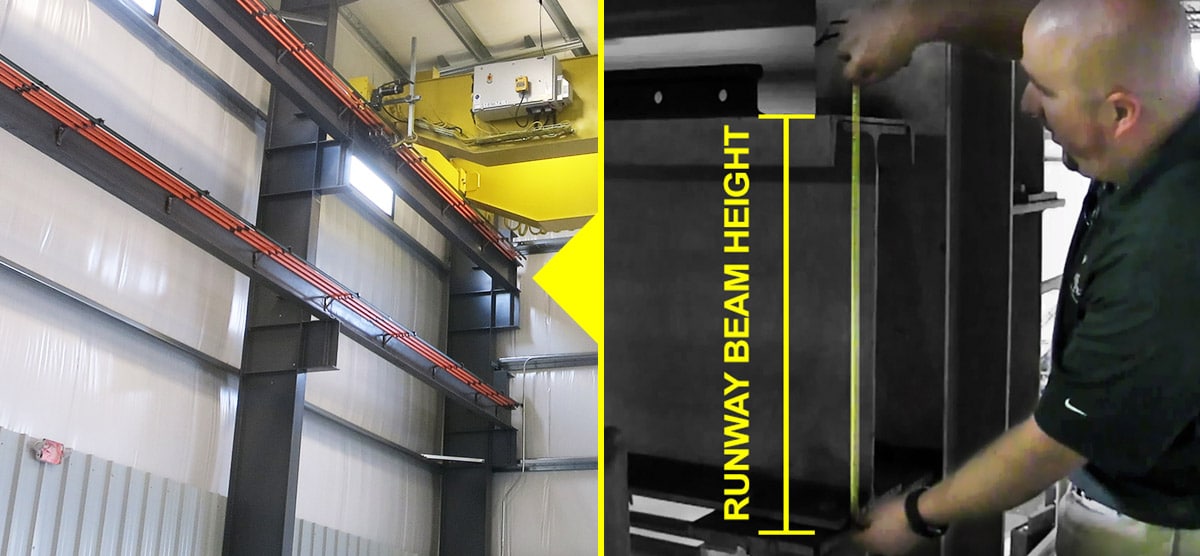

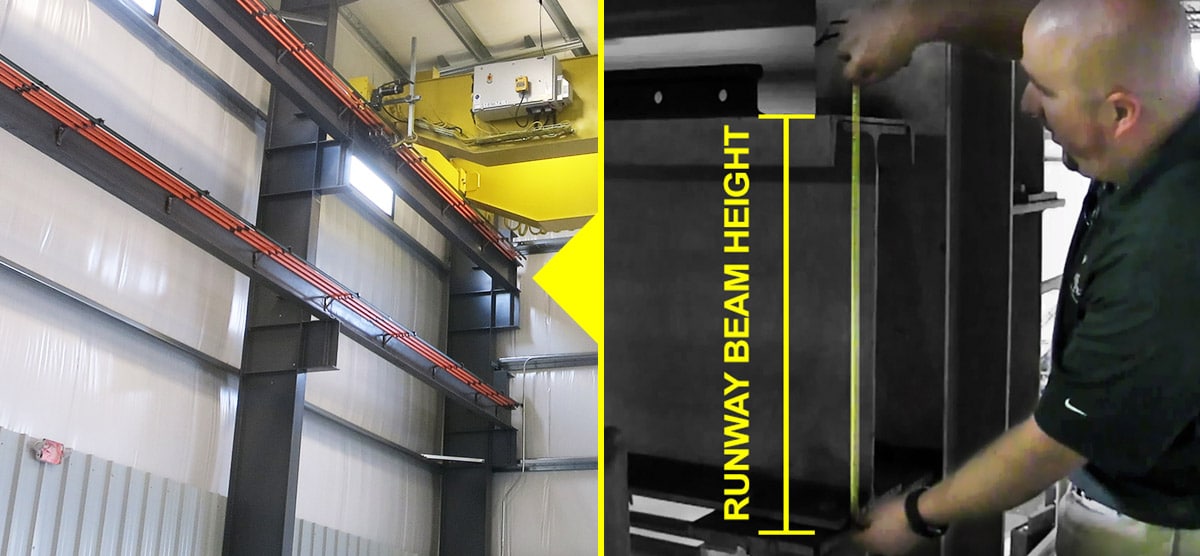

Measuring the Crane’s Runway Beams

Ideally, you will have access to get closer to the runway beams using a lift or nearby mezzanine (if available). If not, you can gather a lot of these measurements using your tape measure or your laser pointer.

Getting measurements of the actual runway beam is as simple as running your tape measure from the bottom of the beam up to the top if you have easy access to the beam. If you can’t get to the beam, you can stand underneath it and use your laser pointer to get a measurement to the top flange, and then get a measurement to the bottom of the beam and subtract the difference. This will give you your beam height. If you’re able to get up close to the beam, you can measure the flange width, as well as the flange thickness.

If the runway beam has a cap channel added for extra reinforcement, getting measurements for the width of the flange, toe, and thickness of the cap will also help the engineering team understand the crane’s design requirements.

Measuring the Crane’s Rail Size

Making sure that you understand the size of the rails will allow you to properly size the wheels. The two most important measurements for the crane rails are the head width and the rail height. This allows the engineering team to identify the size of the rail and determine what size wheels should be used on the crane system. This is important for two reasons:

- You can match the size of the wheels to the size of the rails for proper alignment and tracking of the crane as it moves down the runway. This can help prevent premature or excessive wear of the rails and wheels, but also to the beams and structural supports themselves.

- A properly sized wheel will prevent design changes to the runway rail so the customer can still utilize the original structure in place. This can be a significant cost-savings to the customer if the runway beams and rails can be re-used.

Measuring the Crane’s Span

One of the most important measurements you can provide during an overhead crane consultation is the crane’s span. An overhead crane’s span is essentially its width across the bay—or the measured center-to-center distance between the runway beams. It’s important because it determines how much material is required to build the bridge girders and most significantly affects the cost of the overhead crane.

If your building already has a runway system in place, you can use your laser pointer and place it flush with the runway or building support that the runway is resting on and measure across to the next beam or support. You’ll want to make note of any cantilevers or haunches that the runway beam may be sitting on to determine how far off the building column the center line of the runway is.

During this step, you want to get measurements near the exact measurements to give the estimators and engineers enough information to put a quote together. However, if you move forward with the project, the approval drawings will provide the exact measurements required.

If you’re designing and installing a new crane in your existing facility, then you can use the existing building supports to measure the crane’s span. Take your laser pointer and measure the outer edge distance between parallel building columns. If you have building drawings, you can also use these as a reference or provide the crane manufacturer with a copy of the drawings for their reference.

Measuring the Crane’s Runway Length and Distance Between Supports

The length of the runway is the total overall distance that the crane will move through the facility. Measure out this rough length using the building’s specifications, the setup of your existing production area, or map out or mark off an area you want to be able to utilize for material handling and load movement.

You will also need to determine the measured distance between the building supports that the runway beam will run on top of. To do this, place your laser flush against a building support beam and measure down the length of the runway beam to the next support.

Identifying Obstructions and Measuring for Building Clearance

OSHA 1910.179(b)(6)(i) Overhead and Gantry Cranes states that, “a minimum clearance of 3” overhead and 2” laterally shall be provided and maintained between crane and obstructions in conformity with Crane Manufacturers of America, Inc., Specification No. 61.”

In layman’s terms, this means that when you design your overhead crane system, you must consider any type of overhead obstructions including:

- Water pipes

- Heating and cooling ducts

- Gas or electrical lines

- Overhead light fixtures

- Building headers

You’ll need to know if your crane is a top running or under running design. This will determine the maximum height of your crane system. A top running crane runs on top of the runway beams and will be closer to any overhead obstructions, while an under running crane hangs off of the bottom flange of the runway beam.

You’ll then need to determine how close your crane will be to any of the obstructions mentioned above by measuring from the top of the crane to the bottom of any possible obstruction—ensuring the overhead gap is at least 3” and your crane runway beams and supports are at least 2” from any possible lateral obstruction.