The 16 Biggest Myths in the Lifting and Rigging Industry

From using any chain for an overhead lift to the CE marking meaning "Chinese Export," plenty of myths still exist in the lifting and rigging industry. Our article will review—and debunk—the 16 biggest myths in the industry.

Few industries have changed as much as the lifting and rigging industry. Consequently, best practices from 30 years ago are now an OSHA inspector’s worst nightmare.

Whenever Mazzella’s trainers head to a facility or job site, they hear some variation of these sentences: “We’ve been doing it this way since the beginning. Why would we change it now?” “We can’t afford to adopt a new process. It would slow down our operations.”

Because of how much the industry has changed, plenty of myths still circulate. Most of these myths come from convenience. In the early years, there were no industry standards as comprehensive as the ones we have today.

Today, organizations realize that training is more important than ever. This cycle will only continue if older generations still perpetuate myths to younger generations.

Our article will review—and debunk—the 16 biggest myths in the lifting and rigging industry.

1. A Latch on a Hoist Hook is Optional

Any hoist hook on a job site must have a latch attached.

The only exception would be if the latch creates a hazard to the operator. These examples are usually found in high-heat environments, like a foundry or metal mill. Otherwise, a latch on your hook is essential for safe lifts.

2. Latches Are Required for Sling Hooks

No. While it’s not mandatory, many companies will recommend you put a latch on a multi-leg sling. If the hook was designed to have a latch, put one on.

3. You Can’t Use an Inverted Chain Hoist

While not all chain hoists can be inverted, some can. Inverted hoists are especially common in the entertainment industry, making them a great tool for stagehands who need quick adjustments without climbing a ladder.

However, if you use a hoist with a liquid-type lubricant (oil, transmission fluid, hydraulic fluid), switch the plug with the vent. Otherwise, it will leak. If your hoist uses grease, like the Columbus McKinnon Lodestar, you don’t have to worry about leakage.

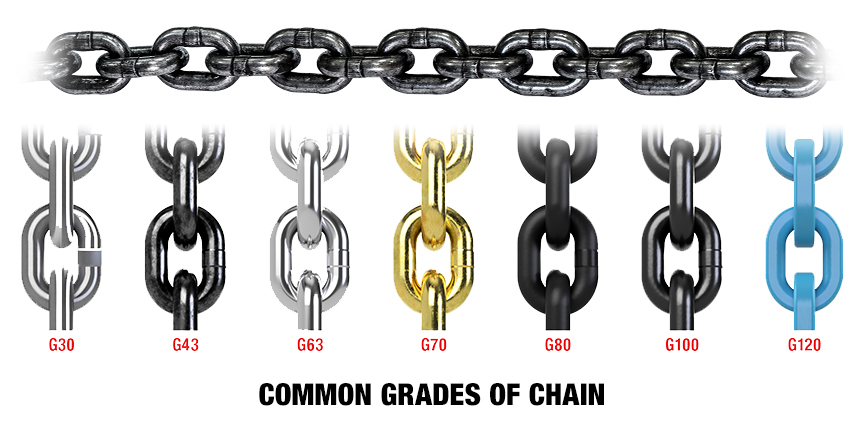

4. You Can Use Any Chain for an Overhead Lift

Both OSHA and ASME recommend Grade 80, Grade 100, or even Grade 120 chains for overhead lifting applications.

The reason? Grade 80 and Grade 100 chains are made from graded alloy steel chain, which provides:

- A higher strength-to-weight ratio

- A much higher elongation percentage—20% minimum—before breaking when overloaded

- Better endurance in extreme heat environments (Grade 80 is mandatory in steel mills)

That elongation gives operators a clear indicator of whether the chain has been overloaded. Meanwhile, carbon chains, such as Grade 43 and Grade 70, are commonly used for tie-down and container securement purposes. They are not recommended for overhead lifting, as they will not provide a visual indication, if overloaded, prior to failure.

What if the Load is Less Than the Working Load Limit?

Regardless of how light the load is, if you use a Grade 30 chain from a local hardware store to lift a load at your job site, and it fails, OSHA will penalize you.

5. ‘Backing it Off’ Is Good Practice for Screwing a Shackle

A popular myth, many riggers think it’s best practice to “back off” a pin on a screw pin shackle by an eighth of an inch to prevent over-tightening when lifting a load.

What ends up happening is the load, when lifted, might go to one side or the other side. This is referred to as the spread, where you could potentially bend the ear of the shackle because you’re putting excessive weight on one side of the shackle.

The proper way to use a screw pin shackle is to tighten it with your hand and not back it off.

6. Carbon Shackles Should Never Be Used for Overhead Lifting

“Since you can’t use carbon chains for overhead lifting, then carbon shackles shouldn’t be used.”

While this logic is understandable, it’s false. Carbon shackles, depending on the application, are fine to use for lifting.

However, don’t assume that similar-sized alloy and carbon shackles have the same working load limit. When comparing shackles of equal specification, most carbon shackles will have a smaller working load limit than alloy shackles.

7. Any Type of Shackle Can Be Used for An Overhead Lift

“As long as the working load limit is greater than the load that you’re lifting, you can use screw pin, round pin, or bolt type shackles, right?”

No. If you look at ASME B30.26 Rigging Hardware, round pin shackles aren’t meant for overhead lifting.

It states:

“NOTE: Round pin shackles are not covered by the scope of this Volume, because they have limited application in lifting. They are only restrained by a cotter pin and may present a hazard in odd angle loading conditions.”

8. You Don’t Actually Need to Use Cotter Pins on Bolt-Type Shackles

Yes, cotter pins have an important purpose. They can be used as a holding device so the nut cannot back out of the shackle.

With a cotter pin, the bolt can rotate 360 degrees while staying secure. If you rotate it without a cotter pin, the nut can back off the pin and cause a load drop.

According to ASME B30.26 Rigging Hardware, if the manufacturer designed the shackle to be used with a cotter pin in place, you must use it.

“For long-term installations, bolt-type shackles should be used; if screw pin-type shackles are used, the pin shall be secured from rotation or loosening.”

9. You Can Use any Shackle Pin as Long as It Fits the Shackle Body

Not all pins are created the same among manufacturers. Pins come in three types of materials: carbon, alloy, and micro-alloy. And even if two pins are the same size, they may have different WLLs depending on the manufacturer.

Some companies, make their pins interchangeable by using the same material for all of their pins. It’s good practice to reach out to the manufacturer to see what they think. It’s also good practice to keep your pins matched with the original shackle to avoid mixup and confusion.

10. If ASME Standards Say ‘Should,’ You Can Ignore It Without Penalty

While ASME can’t fine you for overlooking their standards, OSHA will take care of that.

Regardless of your experience in lifting and rigging, your daily operations are formed by ASME standards. Their standards are created and updated by ASME’s committees, which are made up of former and current:

- Engineers

- Government officials

- Academics

- Industry leaders

Plus, according to OSHA’s General Duty Clause, they can fine you for violating updated ASME standards, ANSI standards, and manufacturer recommendations, even if that standard isn’t in OSHA’s guidelines, regardless of whether it’s a should or a shall.

Your organization should be in the habit of following all applicable industry standards. Even if it does slow down your processes, it creates a safer work environment and keeps you from paying hefty fines.

11. CE Markings on Rigging Hardware Stands for “Chinese Export”

Many riggers believe the CE label on rigging hardware stands for “Chinese Export.” This isn’t true. CE stands for “Conformité Européenne,” and it indicates that the product meets European Union (EU) safety, health, and environmental protection requirements.

When you look at an American-made shackle, and it has the CE marking, that marking indicates it can be sold in Europe.

12. You Should Never Use Turnbuckles for Overhead Lifting

Turnbuckles can be used for specific overhead lifting applications. They are ideal for applications where your load needs to be perfectly level because they allow you to make minute adjustments to the rigging length and height.

We’ve seen power generation facilities use turnbuckle hoists in conjunction to lift the cover off large turbines.

Plus, turnbuckles fall under ASME B30.26 Rigging Hardware standards and best practices for use. In subsection 26-2.9.4. Rigging Practices, it states:

(a) Turnbuckle end-fitting threads shall be fully engaged in the body threads.

(b) Components, including pins, bolts, nuts, or cotter pins used with jaw ends, shall be in good working condition prior to use.

…

(f) The load applied to the turnbuckle should be in line and in tension.

(g) Turnbuckles should not be side loaded.

(h) Turnbuckles should be rigged or secured to prevent unscrewing during lifting or load handling activities.

13. The Red Thread On Web Slings is an Out of Service Gauge

The red thread isn’t a gauge of sling integrity. It is solely an indicator of overloading.

If you see the red thread while lifting, you should pull the sling out of service, but it’s not the sole indicator of the sling’s integrity.

The red thread isn’t made from the same material as the lifting sling. A nylon or polyester web sling will stretch a certain amount before it takes a load. When it gets into the overload condition, it stretches much more, while the red thread doesn’t stretch as much.

What can happen is the red thread becomes visible. That’s an indicator that that sling has been overloaded. Unfortunately, there are people out there who look at it and say, “Well, the red thread isn’t out yet, so it’s fine to continue using.”

The red thread will not account for issues like holes, cuts, and abrasion damage. To see if your sling meets cause for removal criteria, you should follow through with your normal inspection criteria instead of solely relying on the red thread.

It’s also important to note that not all manufacturers include red–core yarns with their synthetic web slings as part of the manufacturing process.

14. You Can Still Use Wire Ropes with Minor Kinks

Any kink, no matter how minor, is cause for removal. Any kink is a sign that the wire rope sling has been stretched past its elastic limit.

Even though the rope is physically intact, internally, the structure is permanently compromised. If you keep bending that wire rope multiple times, whether it’s two lifts or 25 lifts, it will inevitably break and cause a catastrophic failure.

For example, when you bend a paperclip several times, it will eventually break from metal fatigue, even if it looks intact from the outside—the structural integrity of that paperclip is permanently compromised. The same logic applies to wire ropes. The ropes have already been stretched past their elastic limit. While they appear fine on the outside—even with a minor kink—their integrity is permanently compromised.

To avoid kinks and extend the life of your wire rope sling, pair it with sling protection.

15. Rigging is Simple. Anyone Can Do It!

While some rigging is simple and straightforward, other parts of it are incredibly complex.

As we discussed in our Global Lifting Awareness Day article, riggers don’t become experts overnight. While they can come from all social classes, races, religions, or economic backgrounds, riggers spend countless hours learning from experienced workers, on-the-job training, and testing their skills.

There are teams of scientists and engineers who spend their days coming up with formulas and equations to ensure lifts go smoothly and equipment is properly manufactured.

It also depends on what you’re lifting, how you’re lifting it, what you’re lifting it with, and how you’re attaching it.

16. Trainers are Undercover Salespeople and OSHA Sticklers

Many view trainers as an adversary instead of an ally. They’re seen as OSHA shills with no experience in the field who just want to sell you more products.

First, trainers come from all walks of life, and plenty of them come from traditional rigging backgrounds. We’ve seen trainers at our organization with decades of fieldwork. Trainers can also come from an engineering background. Others could be transitioning from a managerial position.

Regardless of their background, trainers know what they are talking about. Many also sit on various industry boards and committees, like the Web Sling Tie-Down Association (WSTDA).

How Can You Improve Your Rigging Processes?

While they may seem like a burden, following updated industry standards and rooting out long-believed myths will improve your job site’s operations.

We understand it can be hard to kick old habits, especially if your experienced coworkers are the ones perpetuating them. Whether it was learning the truth about the CE label, or removing wire ropes with minor kinks, we hope this article equipped you with knowledge that you can bring back to your job site.

Mazzella has been a leader in lifting and rigging training for years now, offering comprehensive, in-house training programs that cover:

- Lifting and rigging

- Fall protection

- Overhead crane operating

- Signalperson

Furthermore, our partnership with Industrial Training International (ITI) helps lifting professionals advance their careers while keeping their operations safe and OSHA-compliant.

Schedule an online, in-person, or job site training session today. Mazzella is also a one-stop shop for all your lifting and rigging needs: fall protection, lifting slings, overhead cranes, below-the-hook lifting devices, crane service, warehouse solutions, and so much more!

Copyright 2024. Mazzella Companies.