OSHA, ASME, and ANSI: What They Do and How They’re Different

In order to help you understand the key roles and differences of OSHA, ASME, and ANSI we’ve developed this article to explain their main functions, how they affect the lifting and rigging industry, and how you can stay compliant.

Whether you’re an executive, a seasoned crane operator, or an entry-level rigger, you have probably heard of OSHA, ASME, or ANSI.

These three organizations play a prominent role in the daily functions of the lifting and rigging industry. But there’s still some confusion about what they do and how much influence they have.

Mazzella has over 70 years of meeting and exceeding industry standards, and we understand that they can be convoluted.

To help clear up any confusion, this article will go over:

- The main functions of OSHA, ASME, and ANSI

- How each one affects the lifting and rigging industry

- How are OSHA, ASME, and ANSI different?

- How to keep your organization OSHA, ASME, and ANSI compliant

What is OSHA?

Created by the Nixon administration in 1971, the Occupational Safety and Health Administration (commonly called OSHA) serves to “ensure safe and healthful working conditions for workers by setting and enforcing standards and by providing training, outreach, education, and assistance.”

As laid out in the Occupational Safety and Health Act of 1970 (OSH Act), organizations must provide workers with safe and healthy work environments. The act also gave the Federal Government power to enforce and set standards. Over the years, these standards have changed to adapt to modern work arrangements.

As part of the United States Department of Labor, OSHA’s administrators report directly to the Secretary of Labor, a member of the President’s cabinet. This status gives OSHA incredible power to enforce laws.

According to their estimates, OSHA oversees the health and safety of an estimated 130 million Americans, over a third of the country’s total population.

How Does OSHA Regulate the Lifting and Rigging Industry?

Companies that are not meeting standards can pay hefty prices. Recently, the cost of OSHA fines has increased. In early 2024, OSHA announced a 3.2% price increase in penalties. There was also a 7.7% increase from 2022 to 2023.

In one example, a contractor in Northeast Ohio was fined $414,000 for repeated fall protection violations. Not only can OSHA fine you, but they can also shut down your operations if enough violations are found.

According to OSHA’s preliminary 2023 data, they cited 7,271 fall protection violations, amounting to over $6 billion in fines. In 2021, there were 680 deaths associated with falls from elevation, accounting for 13% of all workplace deaths that year.

Falls from elevations are also the leading cause of death on construction sites and the second most overall (car crashes being number one). Even with heightened awareness and more emphasis on training, fall deaths have increased in recent years.

Some of the most cited OSHA standards for lifting and rigging are:

• OSHA 1926.503: construction companies must offer fall protection training to any employee exposed to fall hazards

• OSHA 1910.28: employers must provide proper fall protection equipment

• OSHA 1910.184: general sling safety requirements, including frequency and type of inspections

One of Mazzella’s core values is creating safe work environments, and much of what we practice is not only based on OSHA guidelines but goes above and beyond them.

We focus on multiple areas to keep companies OSHA-compliant, including rigging, fall protection, fall protection training, crane inspections, rigging inspections, and more. If you’d like to learn more, check out our OSHA inspection series.

Why do Some States Have Their Own OSHA Departments?

As part of the 1970 OSH Act, states were given the authority to create their own OSHA departments. Currently, 22 states have their own OSHA departments that oversee both public and private sectors. According to our safety experts, state-run OSHA departments tend to have stricter standards.

While these state-run agencies have some autonomy, OSHA must approve and monitor all plans and provide up to 50% of their budget.

Overseeing the most populated state and the fifth largest economy in the world, the California Occupational Safety and Health Administration (Cal OSHA) is the most influential state-run OSHA department.

Because of their unique economic situation, California feels that OSHA isn’t comprehensive enough and differs the most from federal guidelines. If you or your organization is relocating to California, you may have to take new training and workplace certifications.

Other states with their own OSHA program include:

- Washington

- Oregon

- New York

- Nevada

- Wyoming

What is ASME?

While OSHA enforces the standards, many seen in the lifting and rigging industry are designed by the American Society of Mechanical Engineers (ASME). Founded in 1880, this non-profit’s goal is:

“To promote the arts, sciences, and practice of multidisciplined engineering and allied sciences around the globe.”

The organization comprises a vast network of volunteers, including current and former engineers, scientists, academics, government officials, high-ranking executives, and more. Together, ASME’s network focuses on writing and setting standards, codes, and best practices in many industries. According to their website, ASME has over 78,000 members in 145 countries.

ASME is at the forefront in forming industry best practices, whether it’s lifting and rigging, bioengineering, aerospace engineering, or elevators and escalators.

At the moment, ASME has developed over 600 codes and standards for mechanical devices. And according to our lifting and rigging experts, it’s common for ASME to update their standards every three to five years.

Besides setting standards, ASME also offers:

- Learning and development courses

- Certification and accreditation opportunities

- Technical publications and magazines

They also sponsor and host several technical conferences and various educational programs.

How Do ASME’s Standards Affect the Lifting and Rigging Industry?

If you’re using overhead lifting and rigging equipment, your daily operations are formed around ASME’s standards.

One of the best examples of ASME’s influence is the ASME B30 Safety Standard, a comprehensive, 30-volume manual covering safety standards for:

- Cranes

- Rigging equipment

- Hoists

- Material handling equipment

- Below-the-hook lifting devices

Whether it’s tower cranes or articulating boom beams, ASME offers provisions for just about any device you could come across at a work site.

For each piece of equipment, ASME covers the equipment’s:

- Construction and installation requirements

- Inspecting, testing, and maintenance procedures

- Operation requirements – including operator or end-user training

- Scope and definitions

What is ANSI?

Founded in 1918, the American National Standards Institute (ANSI) is a non-profit organization developing performance and quality standards for many products and industries.

ANSI is one of the 170 members of the International Organization for Standardization (ISO), an organization looking to improve and develop international standards.

ANSI’s primary goal is to solidify the United States’ position in the global market, ensuring the nation’s product features and performance levels comply with or exceed current international standards. Like ASME, ANSI’s membership is a diverse mix of academics, government officials, labor union representatives, and public- and private-sector leaders.

Additionally, they play a significant role in sponsoring and accrediting products, organizations, or personnel that meet international standards.

Even though ANSI supervises an organization’s development and use of standards, they don’t develop the standards independently. Instead, they provide a framework, facilitate standards development, and collaborate with other organizations.

How do ANSI’s Standards Affect the Lifting and Rigging Industry?

Like OSHA and ASME, ANSI focuses on safety procedures / practices in the lifting and rigging industry.

An example is ANSI / ASSP Z359, their comprehensive guide for fall protection and restraint best practices.

As a leading provider and installer of engineered fall protection systems, Mazzella reviews ANSI’s standards when we design our products and consult customers.

What are Manufacturer Recommendations?

When purchasing a piece of equipment, it’s important to review the Manufacturer Recommendations. These are instructions, procedures, and recommendations issued by the facility / organization that manufactured the product.

Manufacturer Recommendations can cover multiple topics, including recommended maintenance schedules, potential safety hazards, and ideal work applications.

How are OSHA, ASME, and ANSI Different?

On the surface, OSHA, ASME, and ANSI are similar: four-letter agencies wanting to advance worker safety and uphold industry standards. What separates them is their motives and ability to enforce those standards.

It’s safe to label OSHA as the “enforcer” of the three. While ASME and ANSI write out, endorse, and plan standards, they won’t hand out fines at construction sites or steel mills. OSHA’s status as a federal organization, their 85 area offices, and nearly 2,000 inspectors allows it to keep construction, manufacturing, and industrial companies compliant with industry standards.

ASME is the sole developer for mechanical engineering standards out of these three organizations. In fact, OSHA’s General Duty Clause says that they can fine you for violating updated ASME standards, ANSI standards, and manufacturer recommendations, even if that standard isn’t in OSHA’s guidelines. This clause is a great example of why it’s important to understand all three organizations’ standards.

For many, it’s tough to distinguish ASME and ANSI. While both non-profits want uniform standards and engineering codes, they have different projects and goals. ASME places heavy emphasis on developing standards for mechanical devices, while ANSI focuses on the standards for supplies and products.

It would be fair to label ANSI as a “facilitator” of industry standards. For example, ANSI consulted the American Society of Safety Professionals (ASSP) to create the Z359 fall protection and restraint standards.

How Can You Stay Compliant With OSHA, ASME, and ANSI Standards?

It’s likely your organization has never had an on-site fatality. You may think adding regulations and complying with new standards will slow down productivity. Whatever it may be, OSHA, ASME, and ANSI do not care.

Not only are the fines associated with violations expensive, but failing to keep up with best practices puts your workers at an increased risk of injury or death.

With over 70 years in the lifting and rigging industry, we understand these standards can be hard to follow. Want more information about OSHA, ASME, and ANSI compliance? We have plenty of content covering multiple topics, including our:

- Lifting & Rigging Site Assessment Guide

- Sling Inspections E-Book: A Guide to Inspections & Applicable Standards

- Lifting & Rigging Inspection Frequencies & Records Guide

Furthermore, check out our Toolbox Talk episode on decoding fall protection safety regulations.

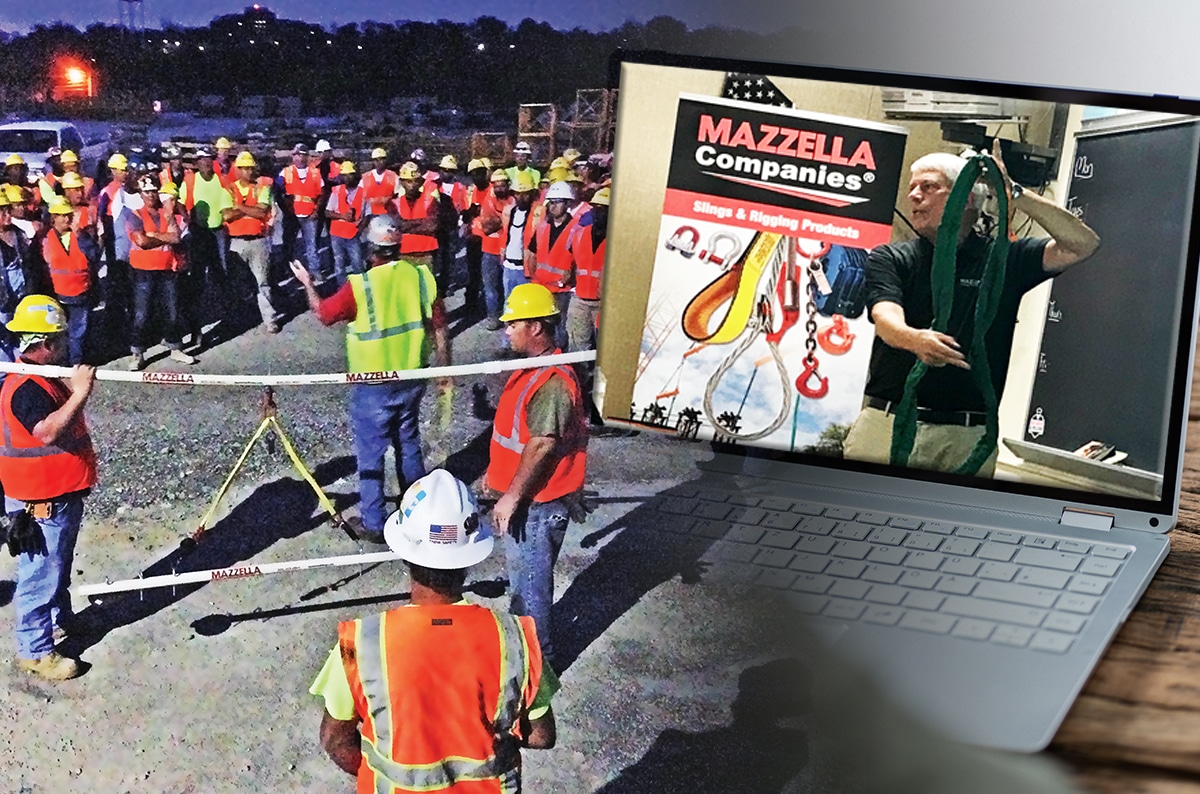

Lifting & Rigging Training

If you require a specific training course for OSHA compliance, Mazzella can assist you in creating a safe and reliable workplace. We qualify our trainers by requiring them to complete an internal train the trainer program (which trains to applicable OSHA and ASME standards and training technique), extensive field experience, and additional training from third-party entities, such as Crosby, CM, Harrington, Gorbel, and Industrial Training International (ITI).

Copyright 2024. Mazzella Companies.