What Are The Different Types of Eye Bolts Used for Overhead Lifts?

It can be confusing to understand what type of eye bolt to use for your application in conjunction with your other rigging gear. We often get asked about usage and what type can be used for a certain lift. In this article, we'll look at the different types of eye bolts, the types of eye bolts that can be used for angular loading, and how that affects the working load limit.

Used as a lifting or securement point, eye bolts are one of the most popular types of rigging hardware. Just like slings, sling hooks, and shackles, eye bolts come in a number of different designs and configurations. Eye bolts can be used as a connection point for rigging, anchoring, pulling, pushing, or hoisting applications.

Although eye bolts are commonly used in industrial applications, they’re also commonly misunderstood or used incorrectly. It can be confusing to understand what type of eye bolt to use for your application in conjunction with your other rigging gear.

We get questions all the time about the different types of eye bolts and how or when they can be used—which is why we wrote this article. We don’t want you to guess or choose incorrectly—that could result in a rigging failure that could cause significant damage or injury!

In this article, we’ll cover the following topics:

- The differences in design between different types of eye bolts

- What types of eye bolts can be used for angular loading

- How angular loading affects the Working Load Limit (WLL) of eye bolts

The Parts of an Eye Bolt

Eye bolts come in different design configurations based on the application and their intended use. Here are some terms you should familiarize yourself with to help you understand the different types and design of lifting eye bolts:

- Eye – loop formed at the top that can be either bent, welded, or forged

- Shoulder – “skirt” where the eye and shank come together designed to resist bending

- Shank – threaded shaft that attaches to the eye

Always ensure that the eye bolt that you select meets or exceeds the working load limit for the task at hand and is comparable to the WLL of the slings and other rigging hardware being used.

Eye Bolt Markings / Identification

According to ASME B30.26 – Rigging Hardware, each eye bolt shall be marked to show:

- Name or trademark of manufacturer

- Size or rated load

- Grade for alloy eye bolts

What Are the Different Types of Eye Bolts?

In this section, we’ll address some terms you may be familiar with, including: shouldered eye bolts, forged eye bolts, nut eye bolts, and machinery eye bolts.

Shouldered Eye Bolts vs. Non-Shouldered Eye Bolts

When selecting the proper eye bolt for your application, one of the most important considerations is whether you need a shouldered or non-shouldered (plain pattern) eye bolt. A shouldered eye bolt can be used for vertical in-line lifts or for angular lifts. Non-shouldered eye bolts should be used for in-line or vertical lifts only and should NEVER be used for angular lifts.

Shouldered Eye Bolts

Shouldered eye bolts are also commonly referred to as “shoulder pattern” eye bolts. These eye bolts are designed with a shoulder at the point where the eye and the shank come together. This shoulder design reduces bending stresses on the shank and allows the eye bolt to be used for angular lifting if the shoulder is properly seated in the load.

When used for side loading or angular loading, you must ensure that the shoulder is completely flush to function properly. Always follow the manufacturer’s specifications and reduction in capacity based on the different angle of loading.

If you are lifting with slings at ANY angle, you must use a shouldered eye bolt.

Non-Shouldered Eye Bolts

Non-shouldered eye bolts are also commonly referred to as “plain pattern” eye bolts. Designed without a shoulder, they can only be used for truly vertical or in-line lifts. Non-shouldered eye bolts are not designed for, or intended to be used for, any type of side loading or angular loading.

Fabrication Processes of Eye Bolts: Forged vs. Bent Eye Bolts

Eye bolts can take their final shape through a process that includes forging or by bending a solid rod into the final eye bolt shape.

Forged Eye Bolts

Forged eye bolts are hammered or pressed into form, which changes the grain structure of the metal to create a stronger, harder, and more durable product. Forged eye bolts are useful for heavier-duty lifting applications as they’re significantly stronger than wire eyes, can withstand loads up to the tensile strength of the material they’re made from, and are available in larger sizes.

When equipped with a shoulder, forged eye bolts can be used for in-line or angular loading.

Bent Eye Bolts

Also referred to as turned eye or wire eye bolts, these eye bolts are made from one-piece that is bent and shaped to form the eye.

Bent eye bolts are used primarily for lighter-duty applications and should not be used for heavy loads, which can cause the eye to open, or for angular loads, which can bend or break the bolt.

Nut Eye Bolts vs. Machinery Eye Bolts vs. Screw Eye Bolts

You can determine the correct type of eye bolt required for the job, by understanding:

- The application or the nature of the lift

- The material or structure the eye bolt is being inserted into (wood, metal, engineered lifting point, etc.)

- If the load angle will be vertical / inline or if there will be angular loading

Nut Eye Bolts

With these eye bolts, the bottom of the shank protrudes through the bottom of the load and is secured in place with a nut. Nut eye bolts can be shouldered or non-shouldered and can be fabricated through forged, welded, or bent eye methods.

Machinery Eye Bolts

On machinery eye bolts, the shank is threaded and is designed to be installed into tapped holes that have been engineered specifically as a lifting point. When equipped with a shoulder, they can be used with angular loads up to 45°.

When installing machinery eye bolts, the minimum thread engagement can be determined using this formula:

Minimum tap depth = basic shank length + half the nominal eye bolt diameter

Screw Eye Bolts

Screw eye bolts are essentially just a screw with an eye. Also commonly referred to as a lag eye, a screw eye bolt has an eye formed on one end and a threaded shank that tapers to a point. They are used primarily for light applications and are screwed into wood or lag anchors. These don’t have a working load limit and are not recommended for use in overhead lifts or with heavy loads.

Eye Bolt Materials

The eye bolt material may be a consideration for you if you need additional corrosion resistance for your application. Two of the most common eye bolt materials are:

Stainless Steel Eye Bolts

Stainless steel will always maintain corrosion resistance when it gets scratched, dinged, or beat up. Stainless is a perfect choice for rigging, tie downs, and other demanding applications. There are many different grades of stainless steel with 304 being the most common. 316 grade can be used in saltwater applications, making it resistant to ocean spray and salt.

Galvanized Eye Bolts

The galvanization process adds a thin zinc coating to protect the metal material from corrosion and oxidization. Galvanized eye bolts can be used in industrial applications where moisture isn’t a primary concern, but where the eye bolts still need to be protected against elements that may cause accelerated corrosion or deterioration to the product.

Angular Loading of Eye Bolts and Rated Capacity

Working Load Limits for eye bolts are based on a straight vertical lift in a gradually increasing manner. Angular lifts will significantly lower working load limits and should be avoided whenever possible. If an angular lift is required, a properly seated shoulder pattern eye bolt must be used.

Loads should always be applied to eye bolts in the plane of the eye, not at an angle to the plane. Angular lifts must never be more than a 45° pull.

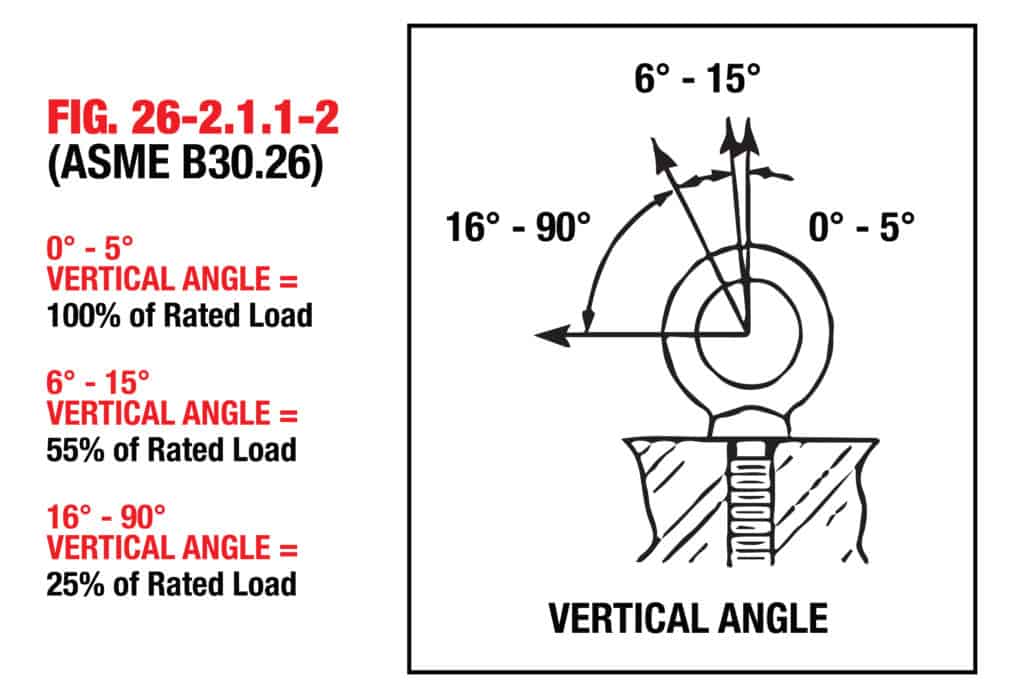

Shoulder Eye Bolts: Working Load Limit Reduction to Vertical Angle (Per Fig. 26-2.1.1-2, ASME B30.26 – Rigging Hardware):

Always consult with the eye bolt manufacturer if you have questions about reduction to WLL in conjunction with an angular load.

Wrapping it Up

When it comes down to it, the most important part of determining what type of eye bolt to use is to have a complete understanding of:

- The total weight of the load

- The application or the nature of the lift

- The material or structure the eye bolt is being inserted into (wood, metal, engineered lifting point, etc.)

- If the load angle will be vertical / inline or if there will be angular loading

- The angle of the sling(s)

- The type of sling(s) being used

- Other rigging hardware being used

From there, you can partner with a reputable rigging shop, or rigging equipment supplier, to determine the best type of eye bolt to use for your application. This will ensure that the design of the eye bolt and its Working Load Limit is adequate for the lifts you’ll be performing.

At Mazzella, we partner with all of the major rigging hardware suppliers in the industry. We can quote and fabricate sling assemblies or get you the individual slings and hardware that you need to put them together yourself.

We offer a full inventory of hooks, shackles, eye bolts and other rigging hardware from the following manufacturers—all of which meets or exceeds ASME design standards:

- Crosby

- CM

- Van Beest

- Gunnebo Industries

- Peerless Industrial Group, Inc.

- And more!

We also provide lifting and rigging training and have certified inspectors to fulfill OSHA/ASME periodic inspection requirements. If you want to schedule a consultation, or receive a quote for your next lifting project, contact one of our Lifting Specialists today

Rigging Hardware

Are you looking for access to a complete inventory of rigging and lifting products from the largest manufacturers in the world?

Contact us if you need shackles, hoist rings, eye bolts, hooks, master rings, links, turnbuckles, and more!

Learn more about lifting and rigging hardware!

Copyright 2019. Mazzella Companies.